Method and system for non-contact powder image development

a non-contact powder and image technology, applied in the field of non-contact powder image development, can solve the problems of uncontrollable charge, undeveloped image, undeveloped image, etc., and achieve the effect of minimizing the impact of undeveloped particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

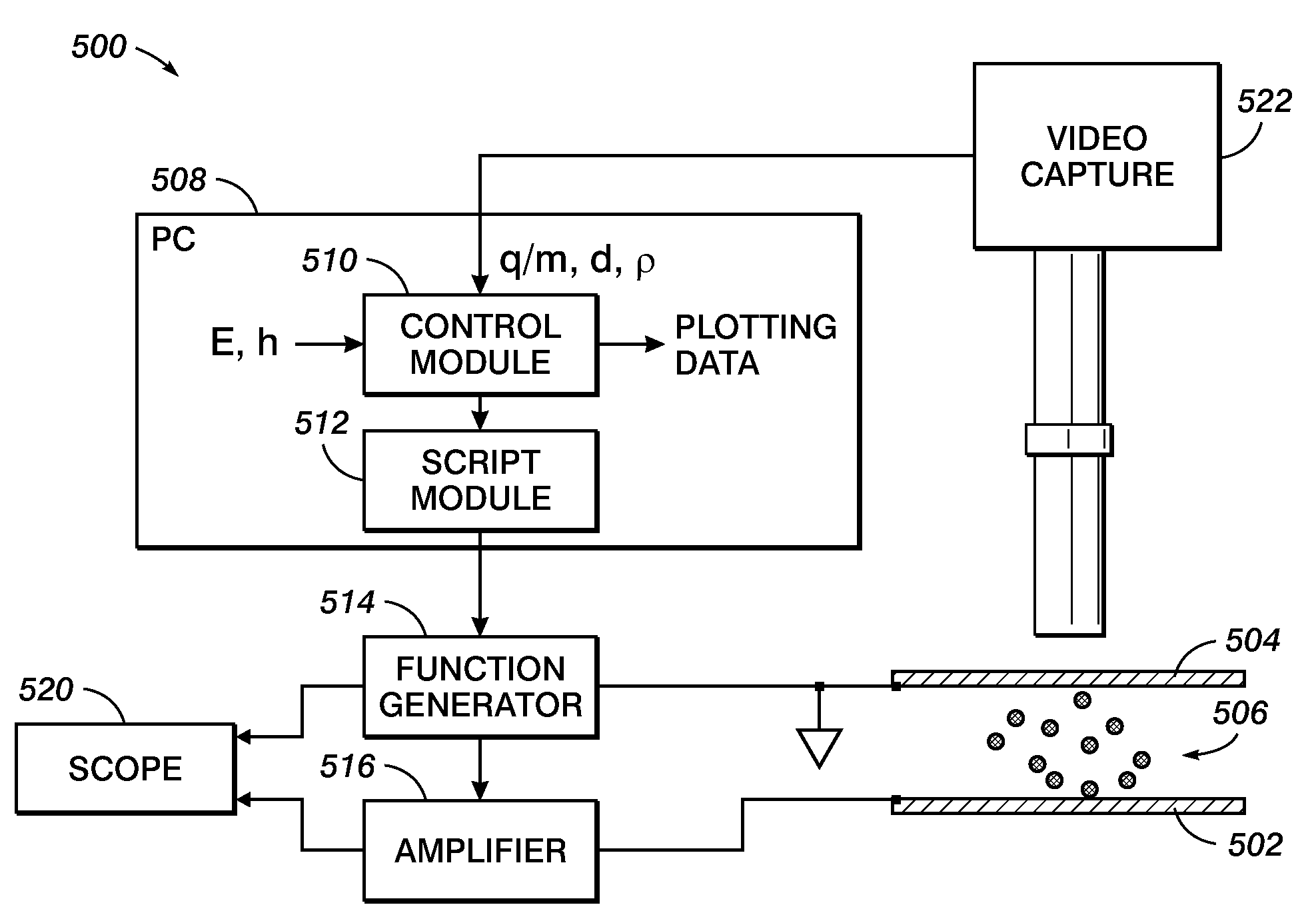

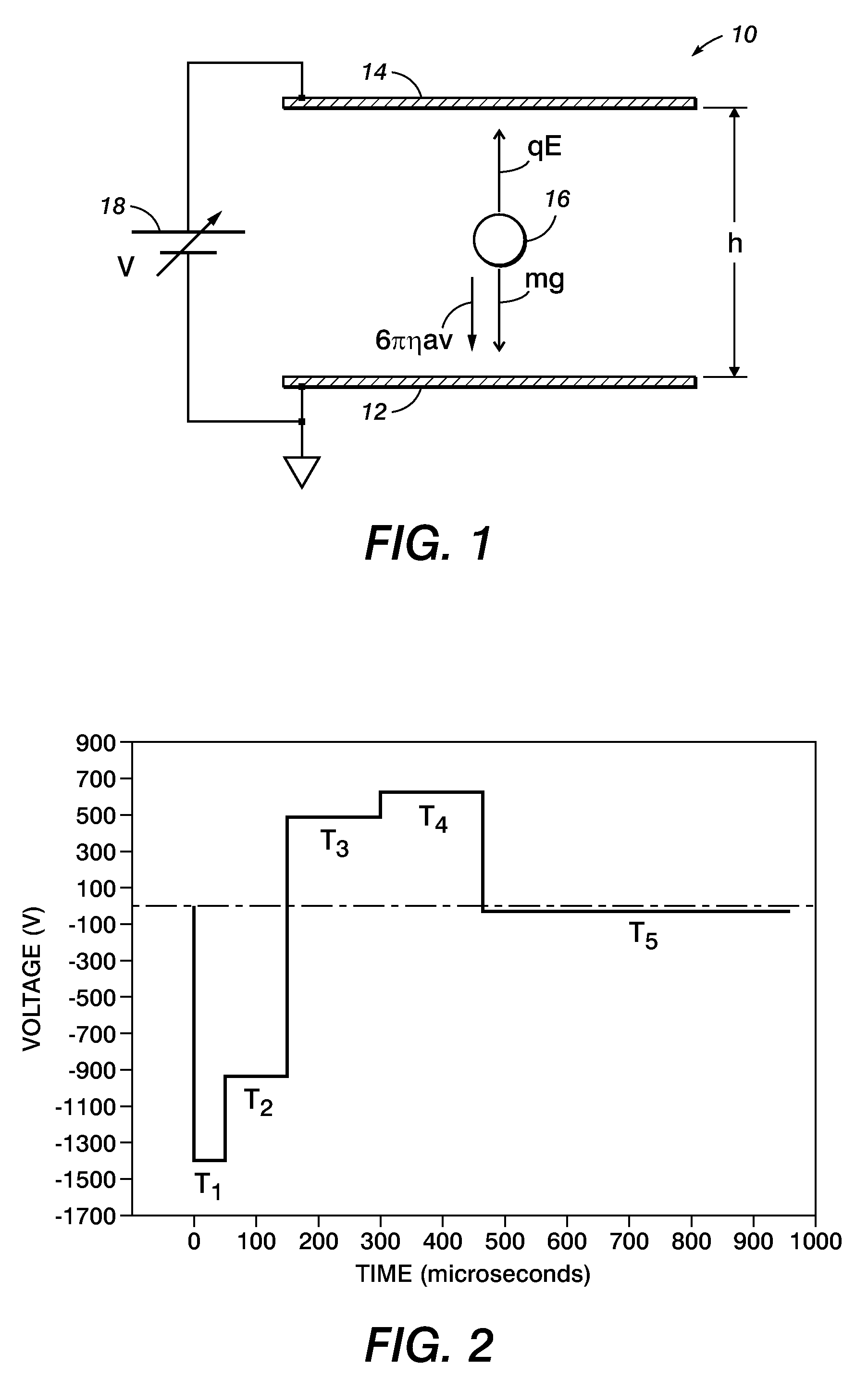

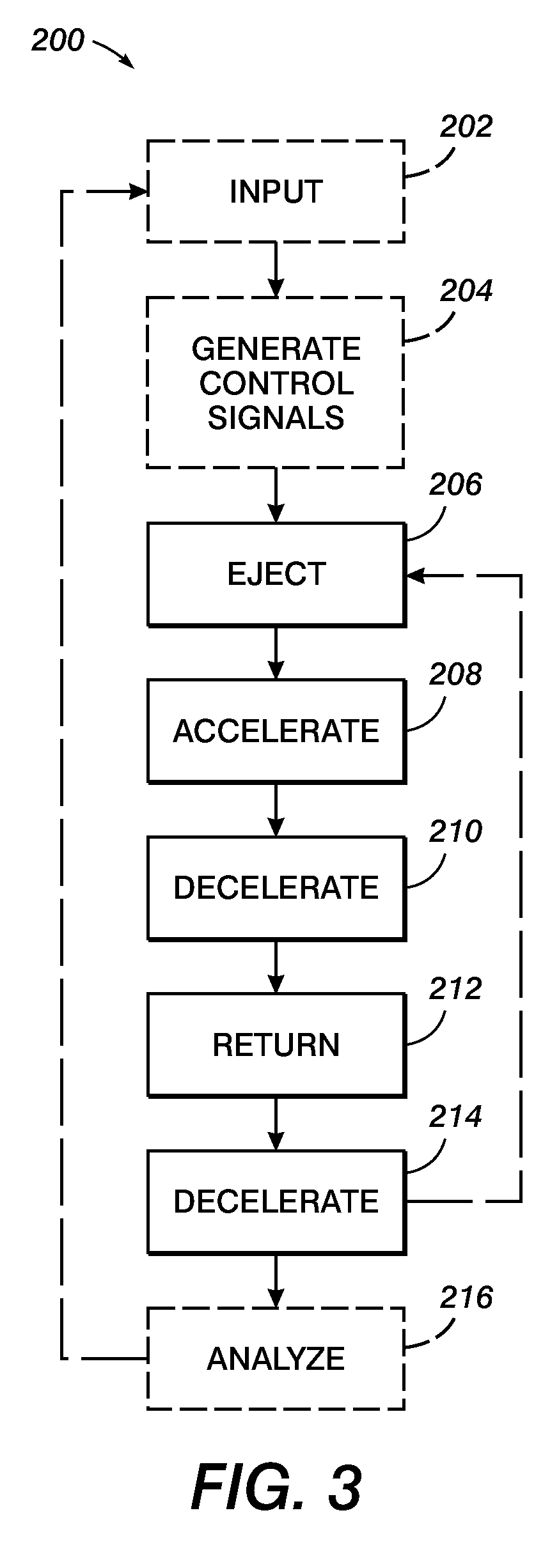

[0030]The presently described embodiments improve upon the prior noted wireless method(s) in at least the following respects: (1) a 5-stage jumping development cycle is implemented where the initial stage is a momentary over-voltage condition to release the majority of the toner on a donor substrate and the final stage includes the implementation of a decelerating potential to minimize the return impact on the donor and, therefore, toner abuse; and (2) a routine is used to directly determine improved (e.g. up to optimal) waveform amplitudes and pulse widths based on toner size and q / m, guided by physical insight. In at least one form, the routine allows for an automation of the process.

[0031]In this regard, given a distribution of particle size and charge, detachment forces have to act over a wide range to overcome the nonlinear adhesion forces of the donor surface to fluidize particles. The contemplated momentary overvoltage serves to so detach the majority of particles with a high

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap