Electrolytic deburring apparatus and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]In this section, some preferred embodiments of the present invention are described in detail sufficient for one skilled in the art to practice the present invention. It is to be understood, however, that the fact that a limited number of preferred embodiments are described herein does not in any way limit the scope of the present invention as set forth in the appended claims.

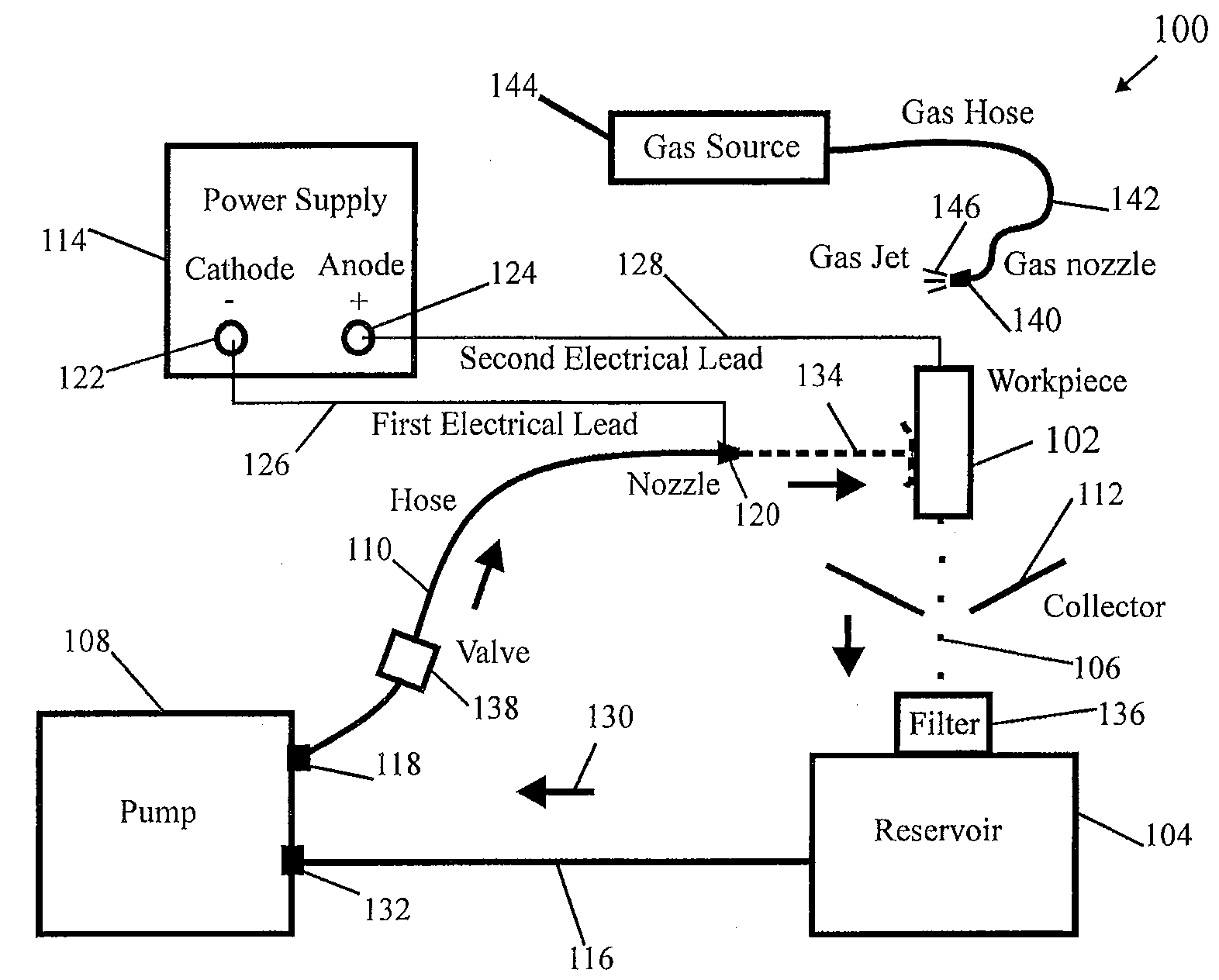

[0018]Referring to FIG. 1, there is shown a schematic representation of an apparatus 100 for toolless electrolytic deburring of a metal workpiece 102 according to an embodiment of the present invention. The apparatus 100 comprises a reservoir 104 containing a quantity of electrolyte 106, a pump 108, a flexible hose 110, a collector 112, and an electrical power supply 114 that is adapted to provide DC current, preferably pulsed DC current. The reservoir 104 is in fluid communication with the pump 108 via a pipe 116. One end of the hose 110 is operably connected to the pump outlet 118 and the other end is attac

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap