Embroidery machine

A technology of embroidery machine and embroidery head, which is applied in the direction of sewing machine components, textiles and papermaking, sewing equipment, etc., to achieve the effect of increasing machine efficiency and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

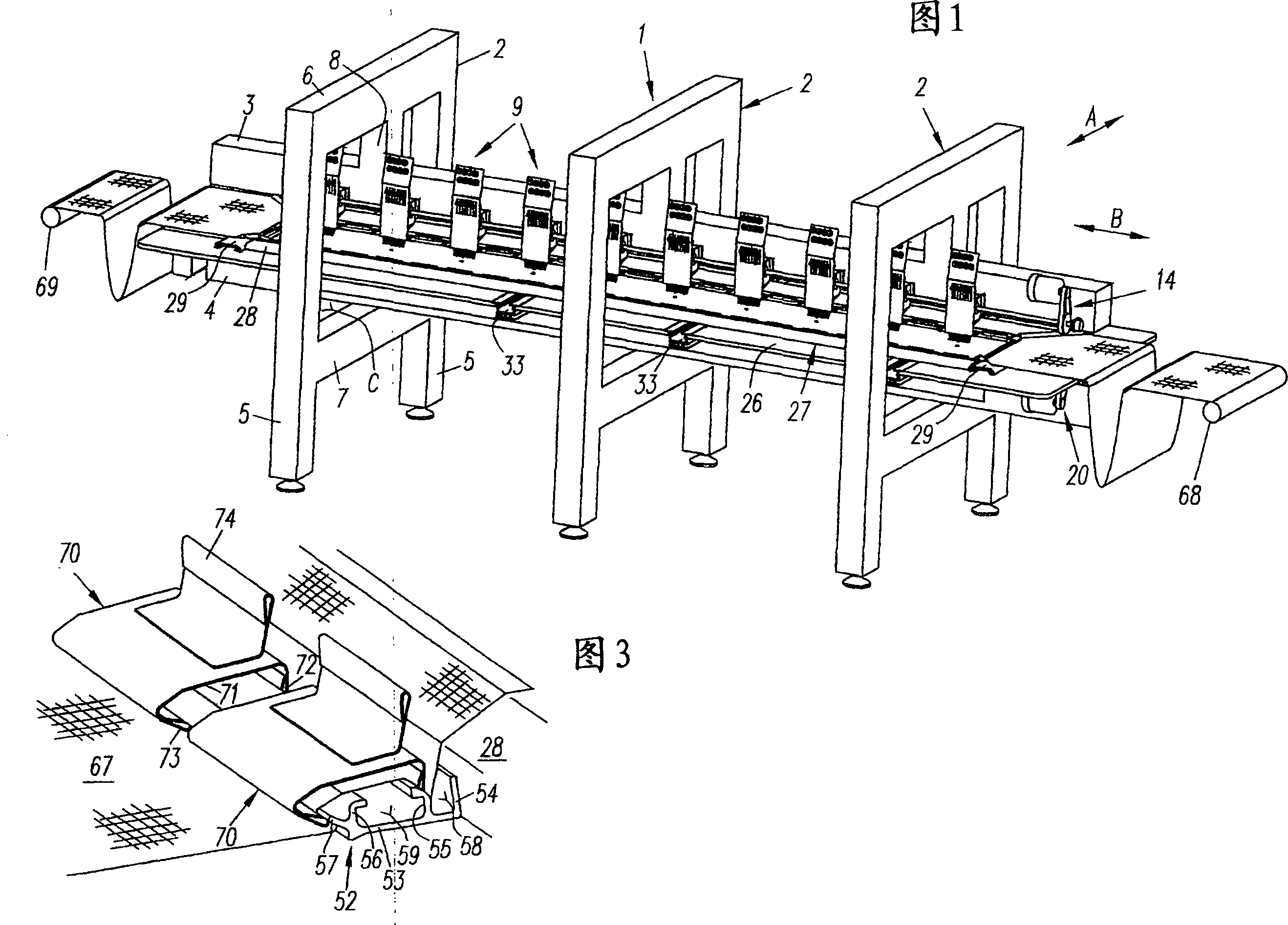

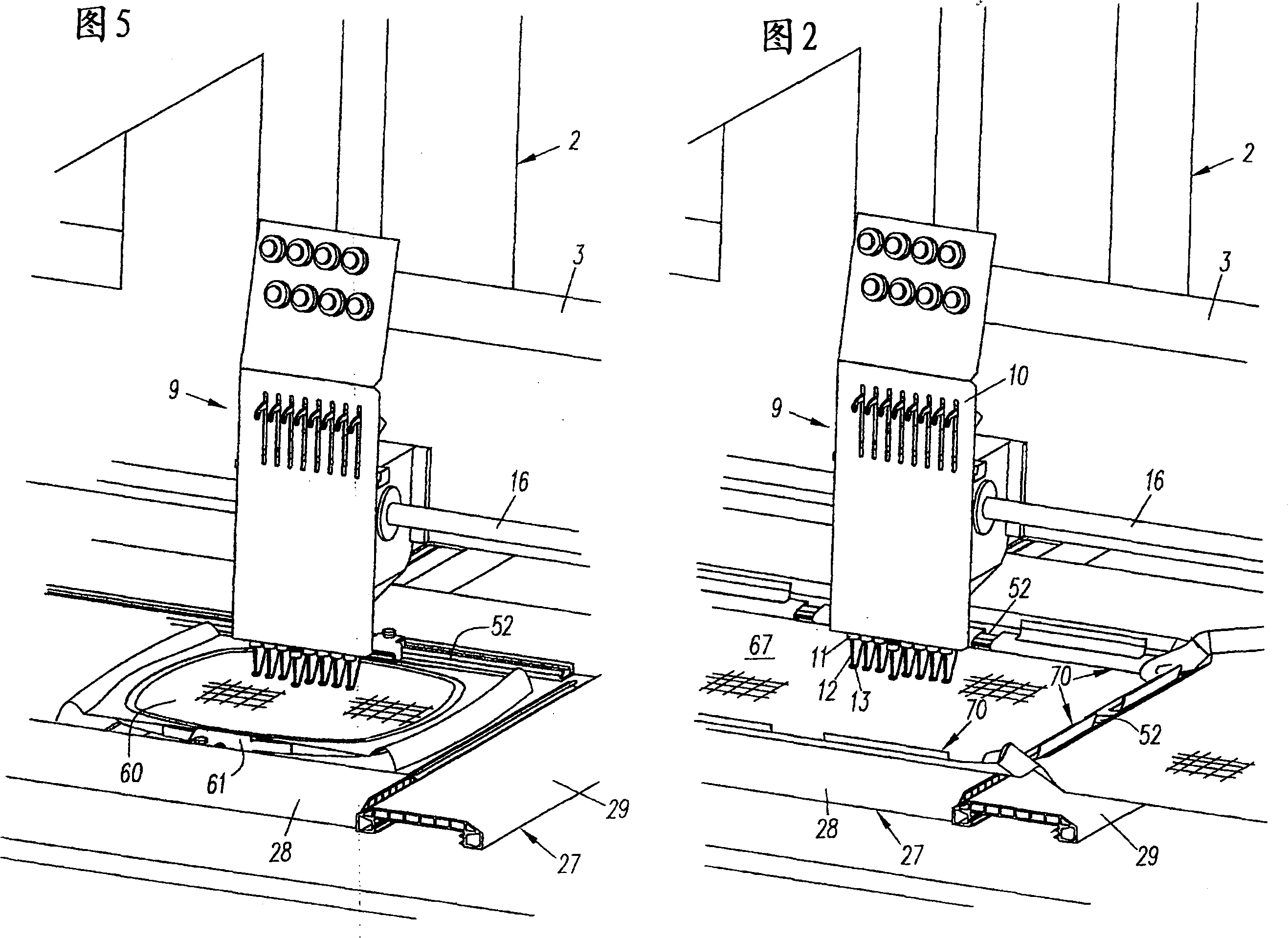

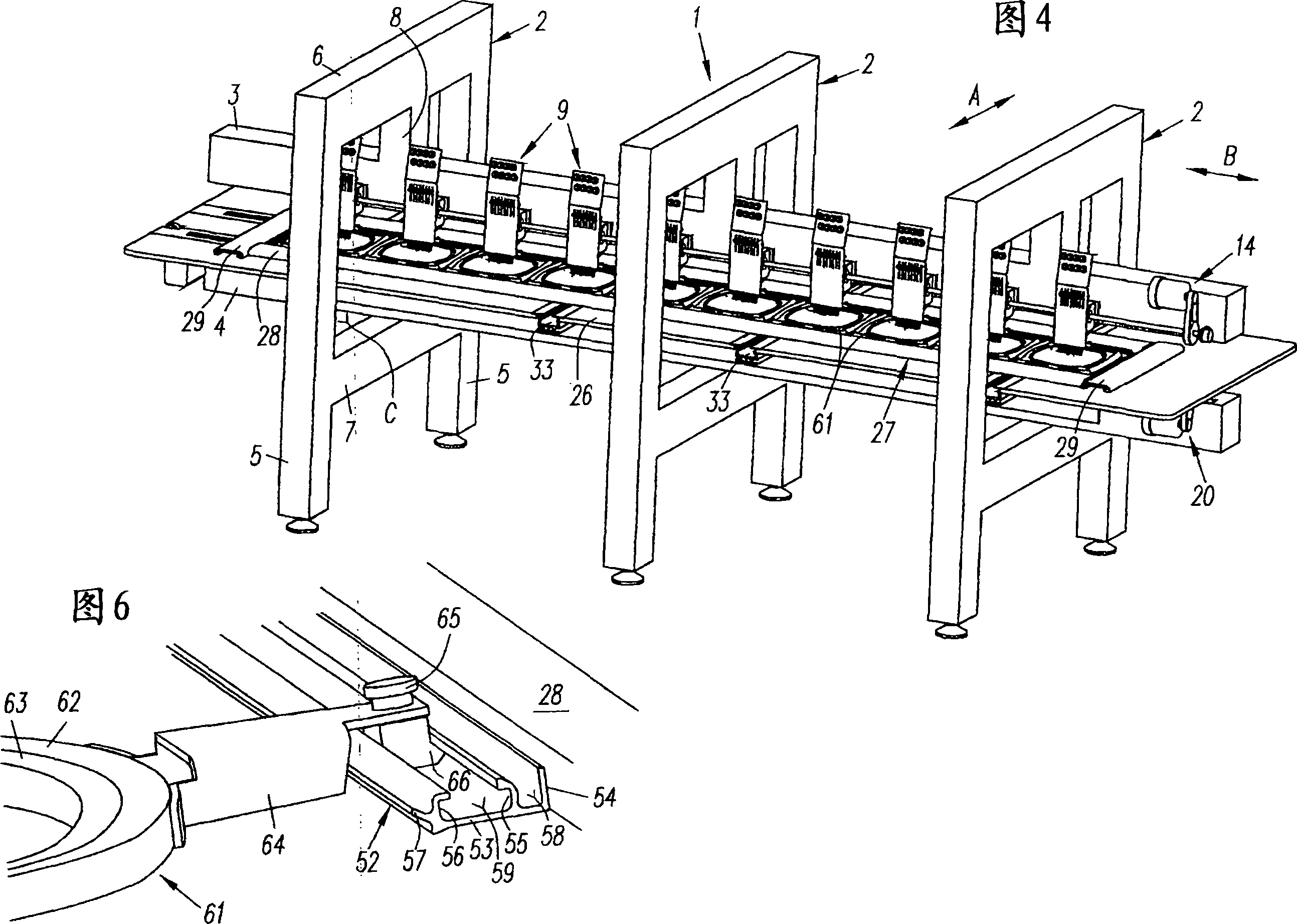

[0023] In the multi-head embroidery machine described in Figures 1 and 4, the frame 1 basically includes three retaining frames 2 arranged in the transverse direction A, forming a bridge and relatively spaced apart, and including an upper supporting beam 3 and an The lower support beams 4 , which run at a distance parallel to the upper support beam, both extend in the longitudinal direction B .

[0024] The holding frame 2 comprises two vertical struts 5 , an upper beam 6 and a lower beam 7 . Each upper cross member 6 has a downwardly directed middle part 8 . The upper support beam 3 is fastened to the lower end of the middle part 8 in such a way that it is at a distance from the underside of the upper transverse beam 6 . The lower support beam 4 instead lies directly on the upper side of the lower cross beam 7 and is likewise firmly connected thereto. The mutually facing inner sides of the vertical struts 5 have a relative distance which simultaneously corresponds to the clear

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap