Vehicle loaded soft expansion square cabin

A vehicle-mounted, cabin-based technology, applied in the field of shelters, can solve the problems of high cost, complex production process, system structure and unfolding operation procedures, heavy overall quality, etc., and achieve manufacturing cost reduction, maintainability and economy Good, easy to operate and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0012] The specific implementation of the present invention will be described in detail below with reference to the drawings and preferred embodiments.

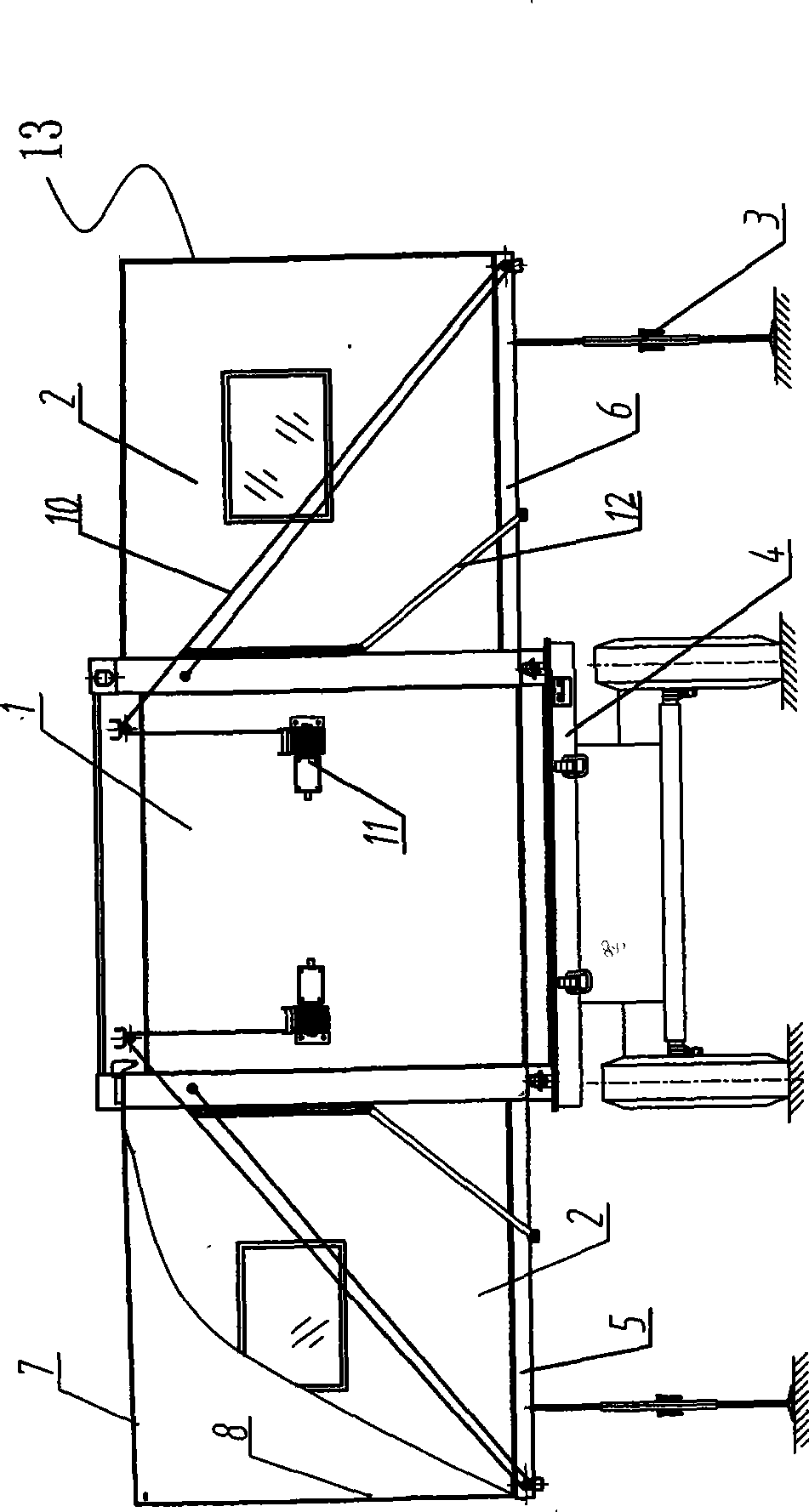

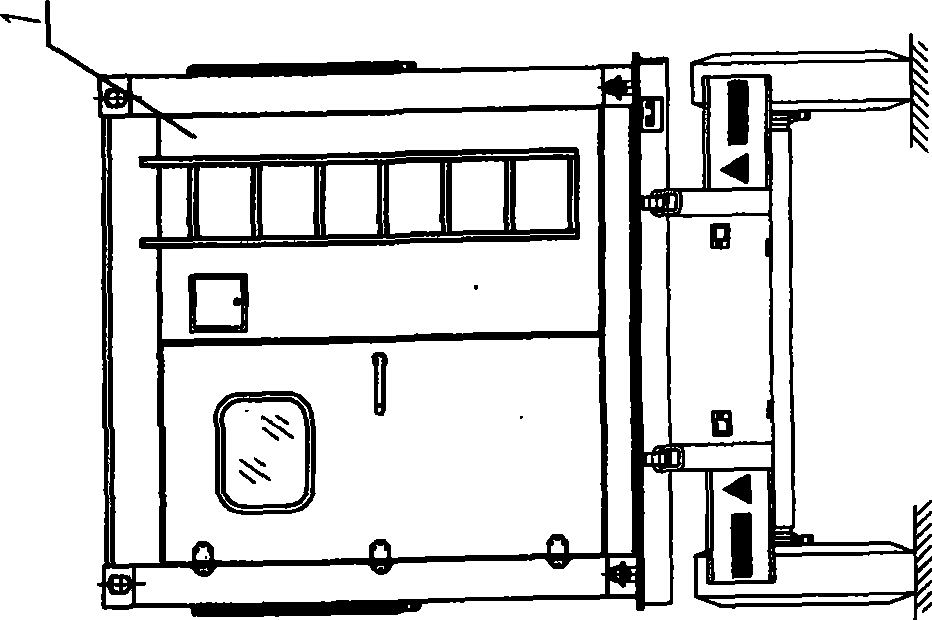

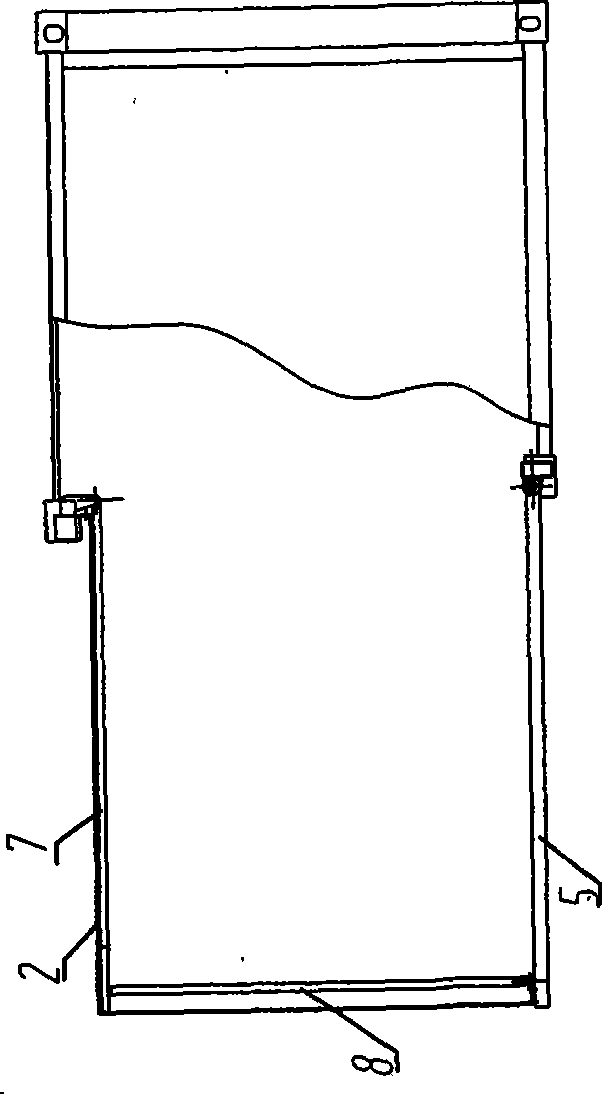

[0013] As shown in the figure, a vehicle-mounted soft expansion shelter includes a shelter body 1 fixed on a special vehicle chassis 4, and the left and right sides of the shelter body are respectively provided with expanded shelters 13, and the expansion The floor of the shelter is composed of the left or right side panels 5, 6 of the unfolded shelter body, and an auxiliary support mechanism 3 connected to the ground is provided on the outside of the unfolded side panel. The extended shelter is composed of an extended power unit, a side extended soft tarp 2, a tarpaulin internal forming support frame 7 and a strut 8 to form a soft extended shelter, and the left or right side panel of the shelter body is connected with the extended power unit The inner forming support frame 7 and the strut 8 of the tarpaulin are mainly folded and un

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap