Multi-bottle type manual cork pressing device

A wine and manual technology, applied in the field of cork stopper of wine bottles, can solve the problems of inconvenience of movement, inapplicability to multi-variety, multi-bottle and small-scale special-shaped bottles, etc. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

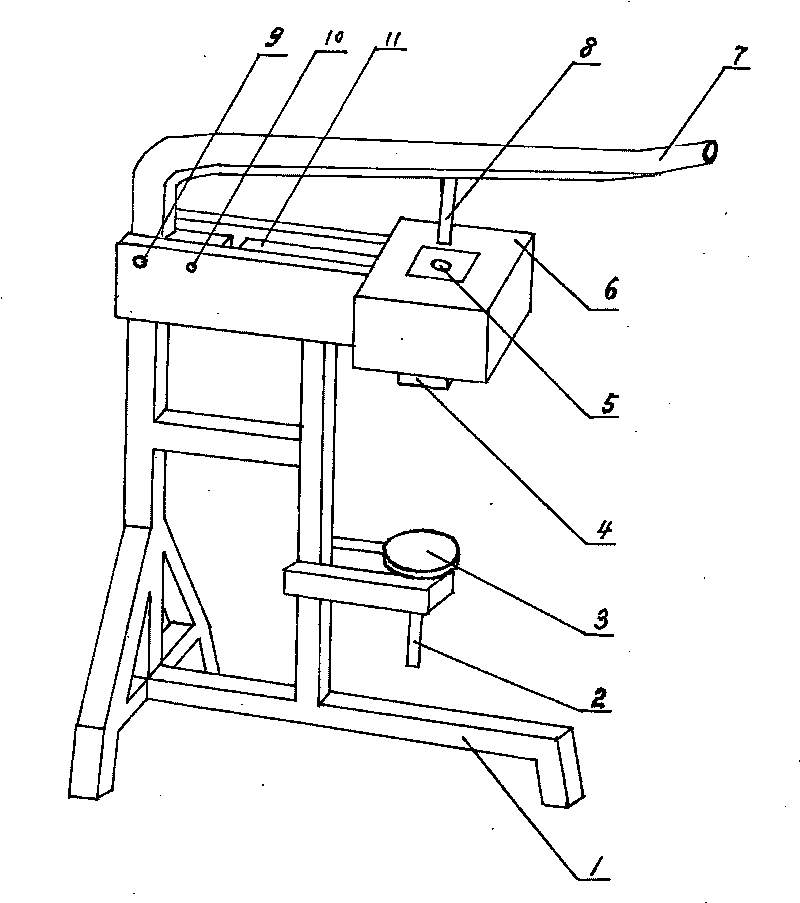

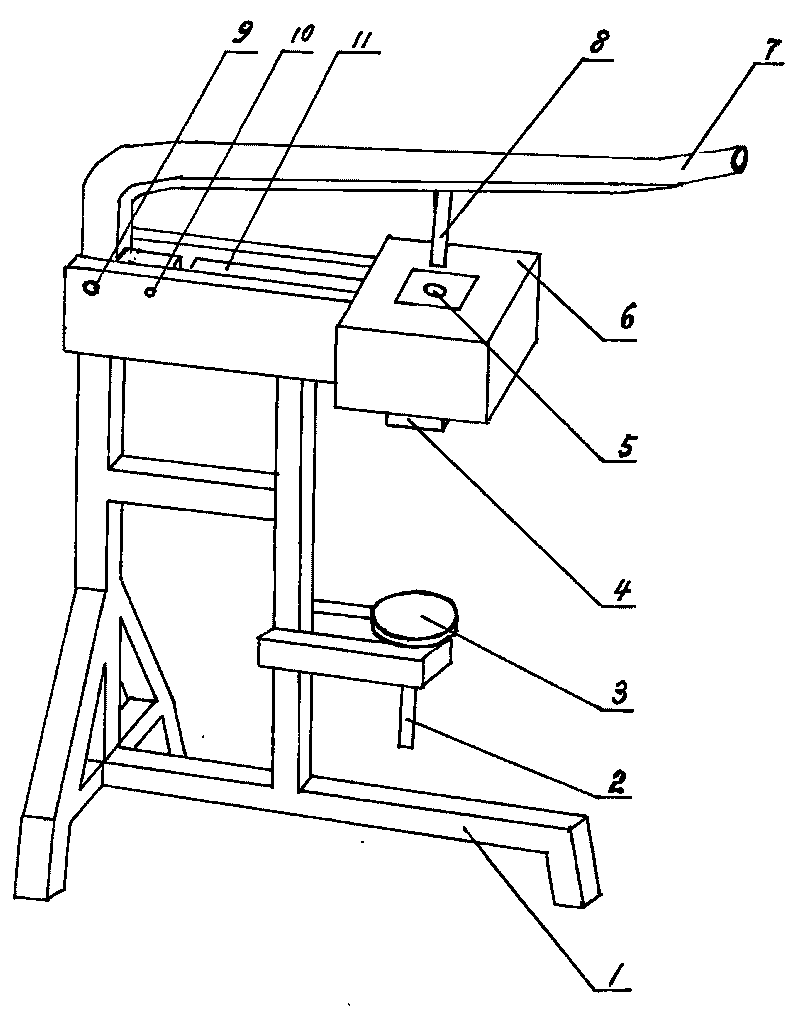

[0009] In the figure 1, the frame body of the manual corking device 2, the lifting screw 3, the bottle supporting positioning plate 4, the bottle mouth positioning device 5, the replaceable corking device 6, the cork retracting device outer box 7, the lever arm handle 8. Plugging post 9, pin 10, plugging push rod pin 11, plugging push rod

[0010] From figure 1 It can be seen that a liftable lead screw 2 is installed on the pillar at the bottom of the frame body 1, and the top of the liftable lead screw 2 is fixed with a bottle support positioning plate 3; In the middle of the outer box 6 of the plug device is a replaceable plug retracting device 5; the replaceable plug retracting device 5 is respectively connected to the outer box 6 of the cork retracting device by bolts, and the plug retracting push rod 11 is connected to the replaceable plug retracting device through a pin shaft The bottle mouth positioning device 4 is fixed on the bottom of the outer box 6 of the cork retrac

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap