Transformer of high-frequency spark vacuum detector

A detector and transformer technology, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problems of high material consumption, large volume, easy to burn, etc., to reduce magnetic flux leakage, compact structure, and improve the efficiency of electromagnetic induction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

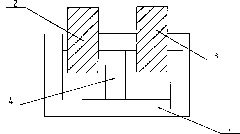

[0009] Such as figure 1 As shown, the transformer includes a rectangular iron core 1, and a primary wire package 2 and a secondary wire package 3 are wound side by side on one side frame of the rectangular iron core, and a choke The iron core 4 is separated, and the choke iron core is connected between the frame where the two wire packages are located and the frame on the opposite side.

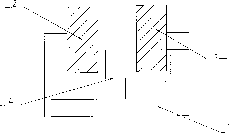

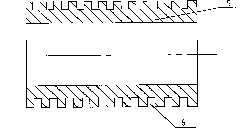

[0010] The primary wire package and the secondary wire package are composed of a bobbin 5 and a coil wound on the bobbin, and the wires are as figure 2 As shown, a plurality of winding slots 6 separated by partitions are arranged side by side on the periphery of the coil bobbin 5, and the coil is wound on the coil bobbin slot by slot.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap