Aircraft catapult utilizing hydraulic power and hinge connecting rod structure

A hydraulic power and catapult technology, which is applied in the field of aircraft catapults, can solve the problems of reduced efficiency and air leakage, and achieve the effects of low cost, simple process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific examples.

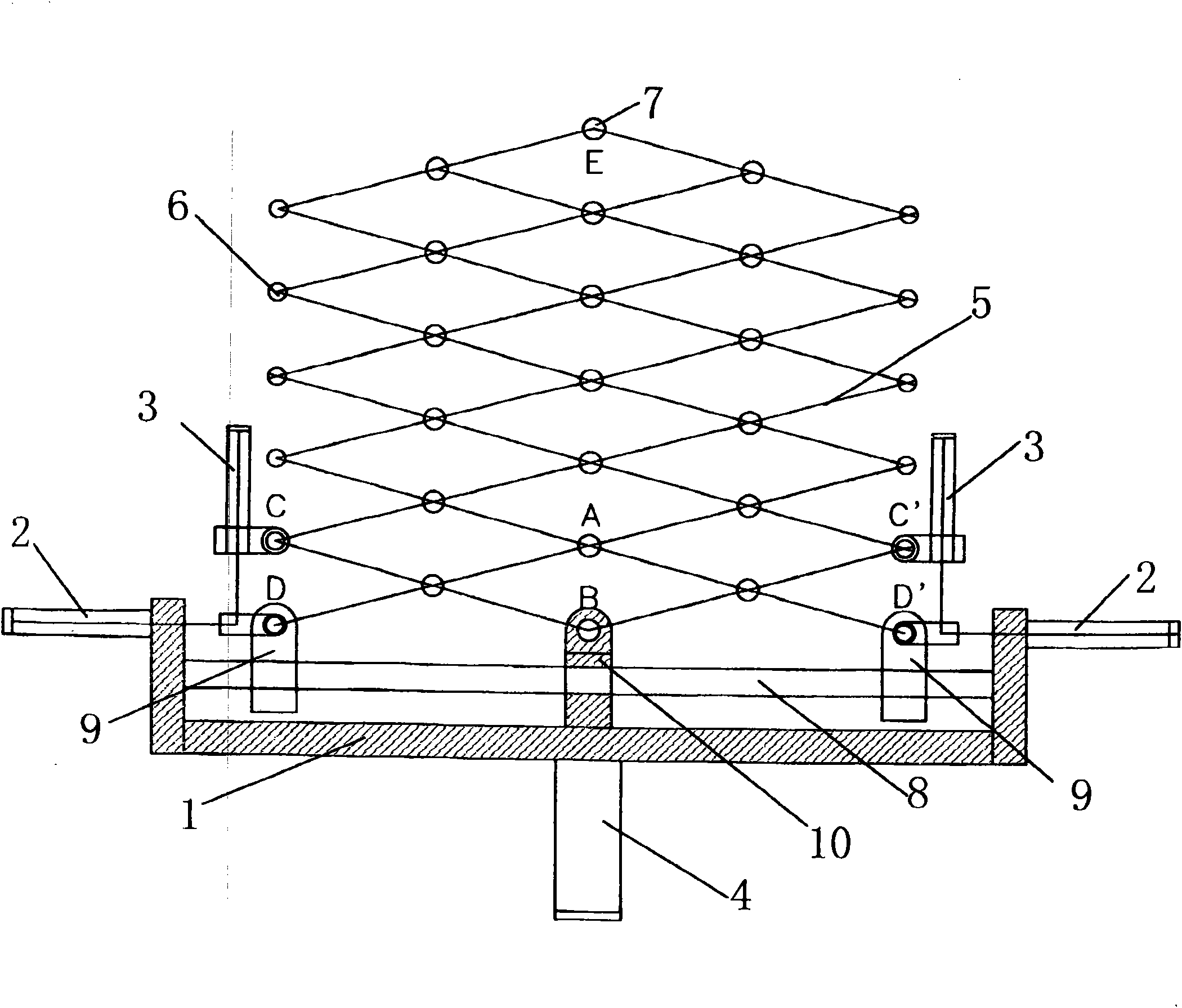

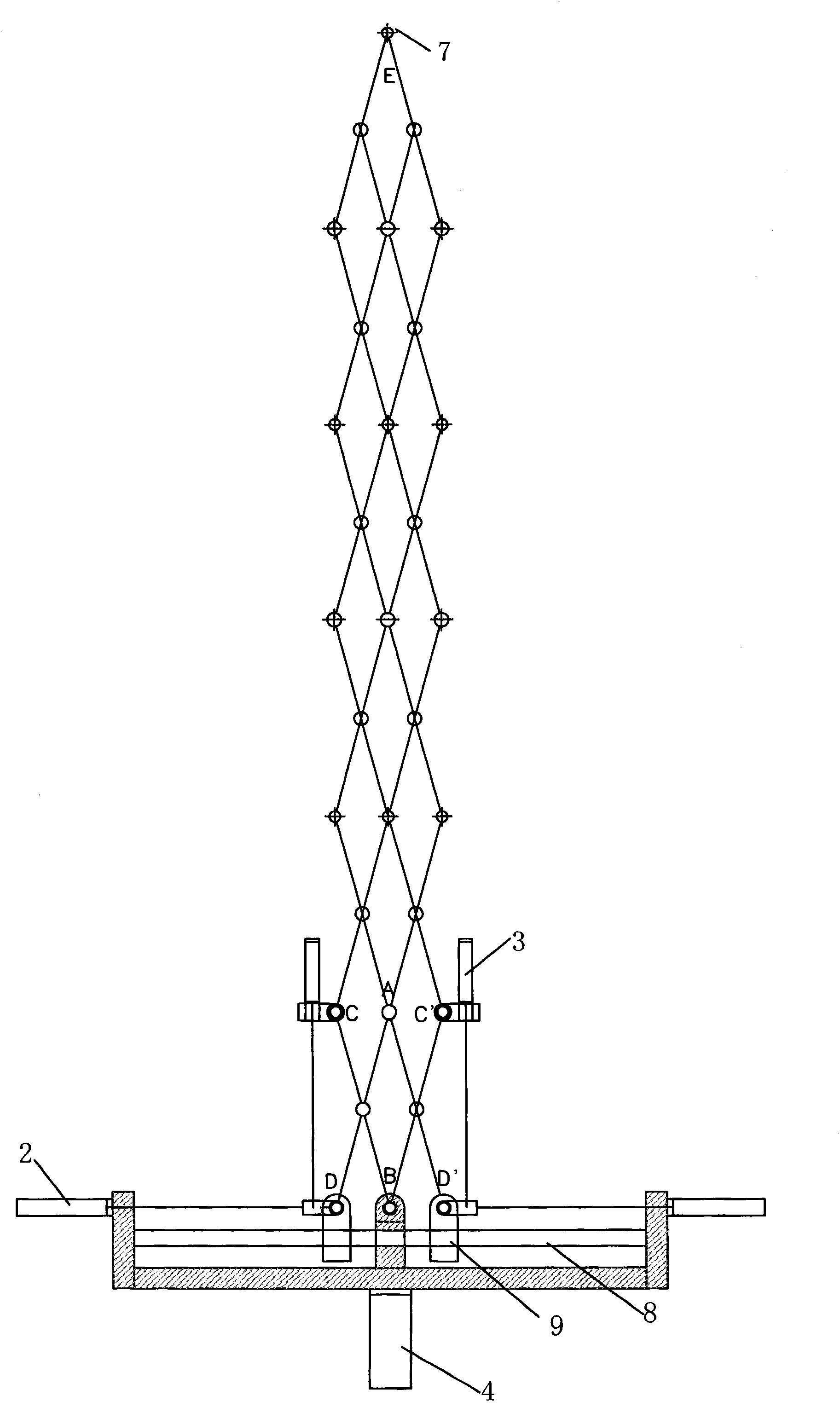

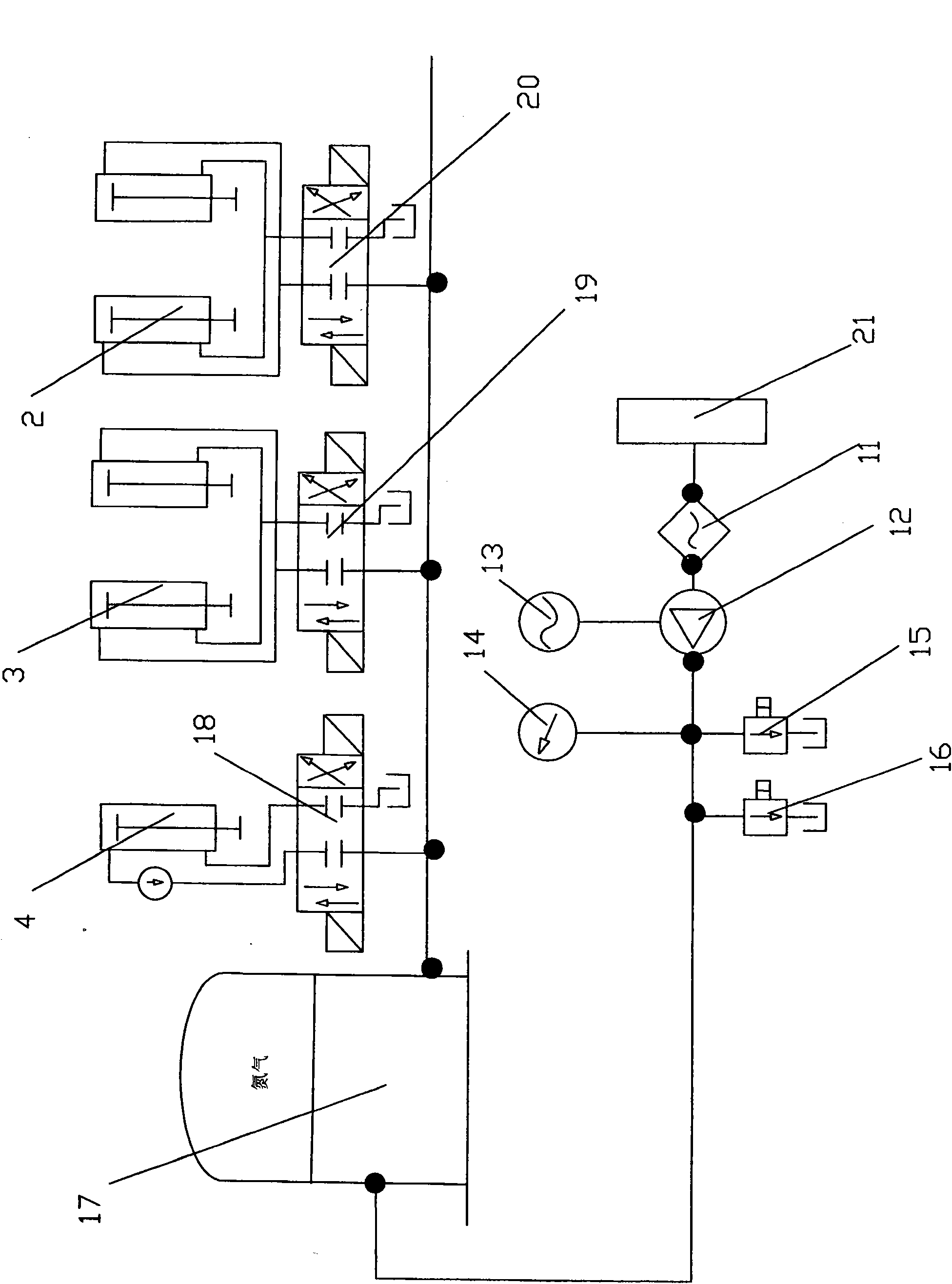

[0034] The present invention is a quick catapult using hydraulic power, its mechanical transmission structure adopts a hinge linkage mechanism, the mechanical transmission structure of the catapult is fixed on the machine base 1, and the hydraulic transmission part is composed of 5 high-pressure oil cylinders, which are respectively 1 load-bearing seat oil cylinder 4, 2 horizontal oil cylinders 2 and 2 vertical oil cylinders 3, and a hinged structure is adopted between each connecting rod 5 of the hinge link structure. Bearing seat oil cylinder 4 fronts are horizontally provided with guide rod 8, and guide rod 8 two ends are respectively provided with twisted ear seat 9, and twisted ear seat 9 can slide along guide rod 8.

[0035] Bearing base oil cylinder 4 is installed on

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap