Tilting-type operating platform used for processing three-dimensional hole of die

A three-dimensional hole and worktable technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of low efficiency, inability to guarantee accuracy, and complicated adjustment, and achieve accurate positioning, convenient height calculation, and firm support. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

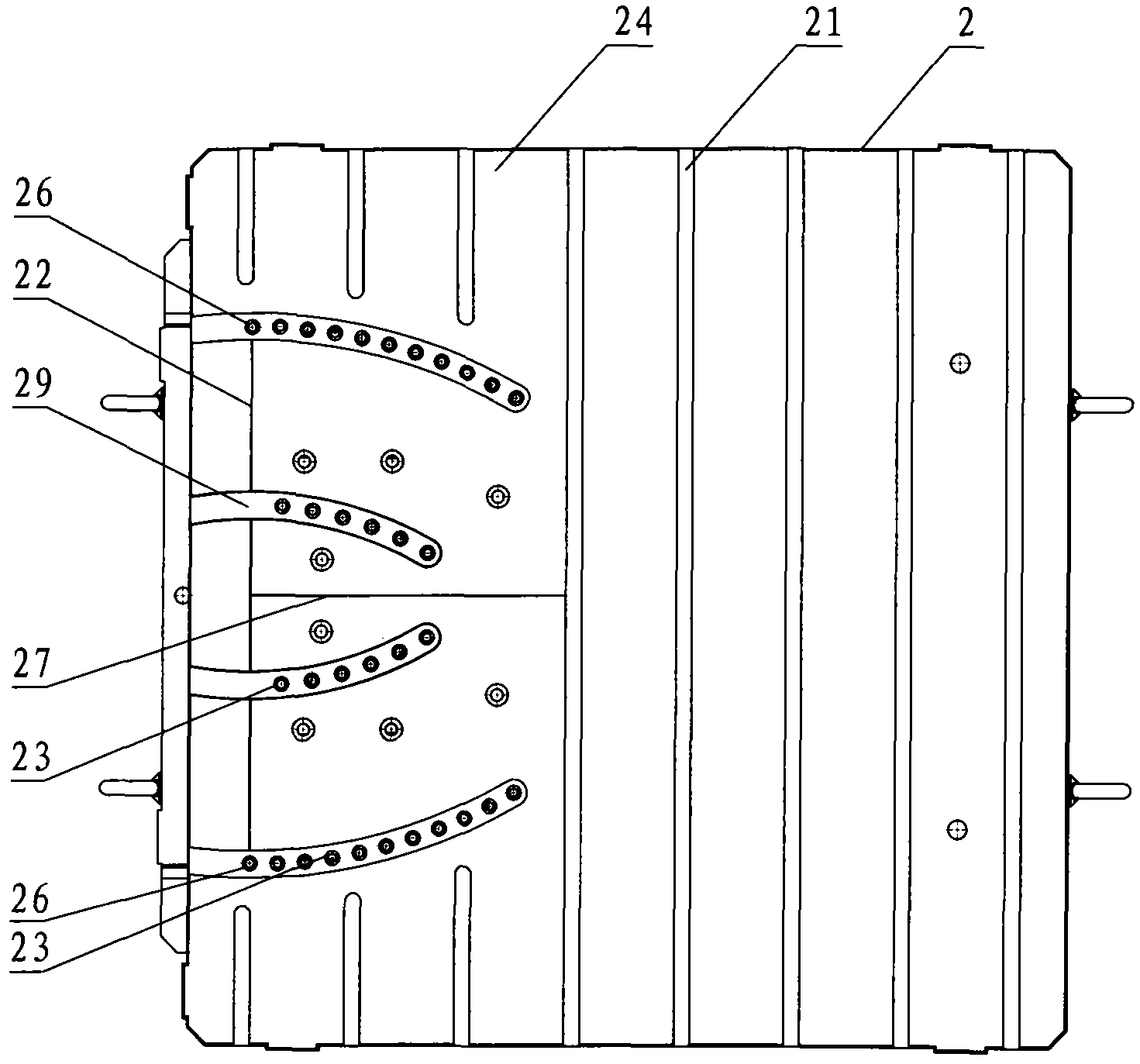

Embodiment 2

[0039] The structure and principle in this embodiment are basically the same as those in Embodiment 1. The main difference is that 6 rows of positioning holes 23 are provided on the upper surface 24 of the working plate 2, and 3 rows of positioning holes 23 on one side of the line of symmetry 27 are provided respectively. On the circular arc with the reference hole 26 on the other side of the line of symmetry 27 as the center and three unequal diameters; the row of positioning holes 23 on one side of the line of symmetry 27 has fifteen positioning holes 23 away from the line of symmetry 27, and the fifteen positioning holes 23 The first positioning hole 23 extends at an equal angle to the line of symmetry 27 at an angle of 2 degrees with the reference line 22 as the starting point. included angle; the middle row has ten positioning holes 23, and the ten positioning holes 23 extend at an angle of 3 degrees to the line of symmetry 27 with the reference line 22 as the starting point,

Embodiment 3

[0040] Embodiment three: the structure and principle among the present embodiment are basically the same as embodiment one, and its main difference is that the upper surface 24 of the working plate 2 is provided with 8 rows of positioning holes 23, and 4 rows of positioning holes on one side of the line of symmetry 27 The holes 23 are respectively arranged on four circular arcs with unequal diameters centered on the reference hole 26 on the other side of the line of symmetry 27 . Among the positioning holes 23 on one side of the line of symmetry 27, there are fifteen positioning holes 23 in the row away from the line of symmetry 27. The fifteen positioning holes 23 take the reference line 22 as the starting point and extend to the line of symmetry 27 at an equal angle of 2 degrees. There is an included angle of 30 degrees between the line connecting the hole 26 and the farthest positioning hole 23 away from the reference line 22 and the reference line 22 . One of the two rows in

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap