Pipeline quick service clamp sleeve joint

A technology of casing joints and clamps, which is applied in the field of quick-repair clamps and casing joints of pipelines, can solve the problems of uneconomical maintenance, excessive consumables, and prolonged repair time, and achieve simple and compact structure, improved connection strength, and shortened repair time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

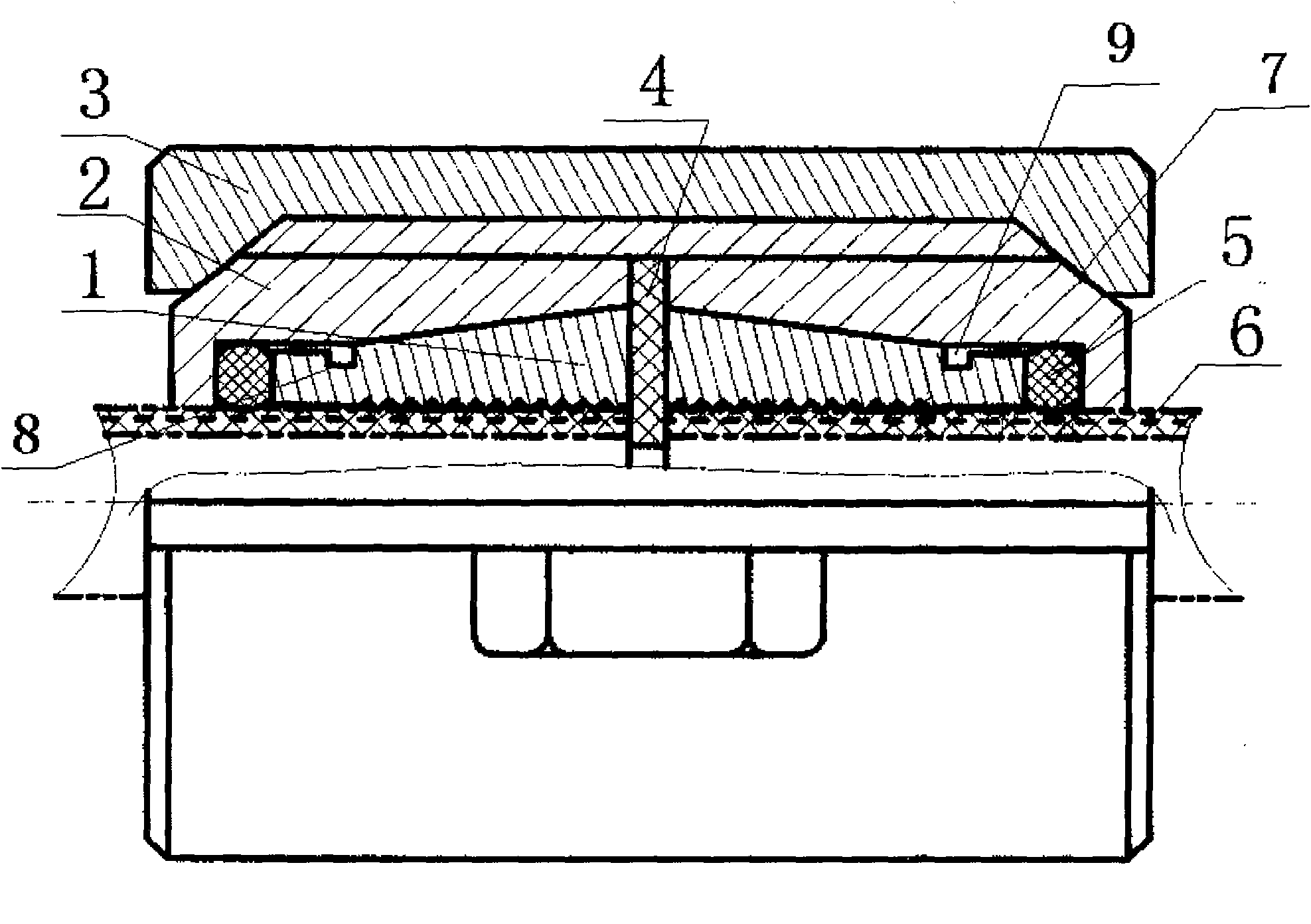

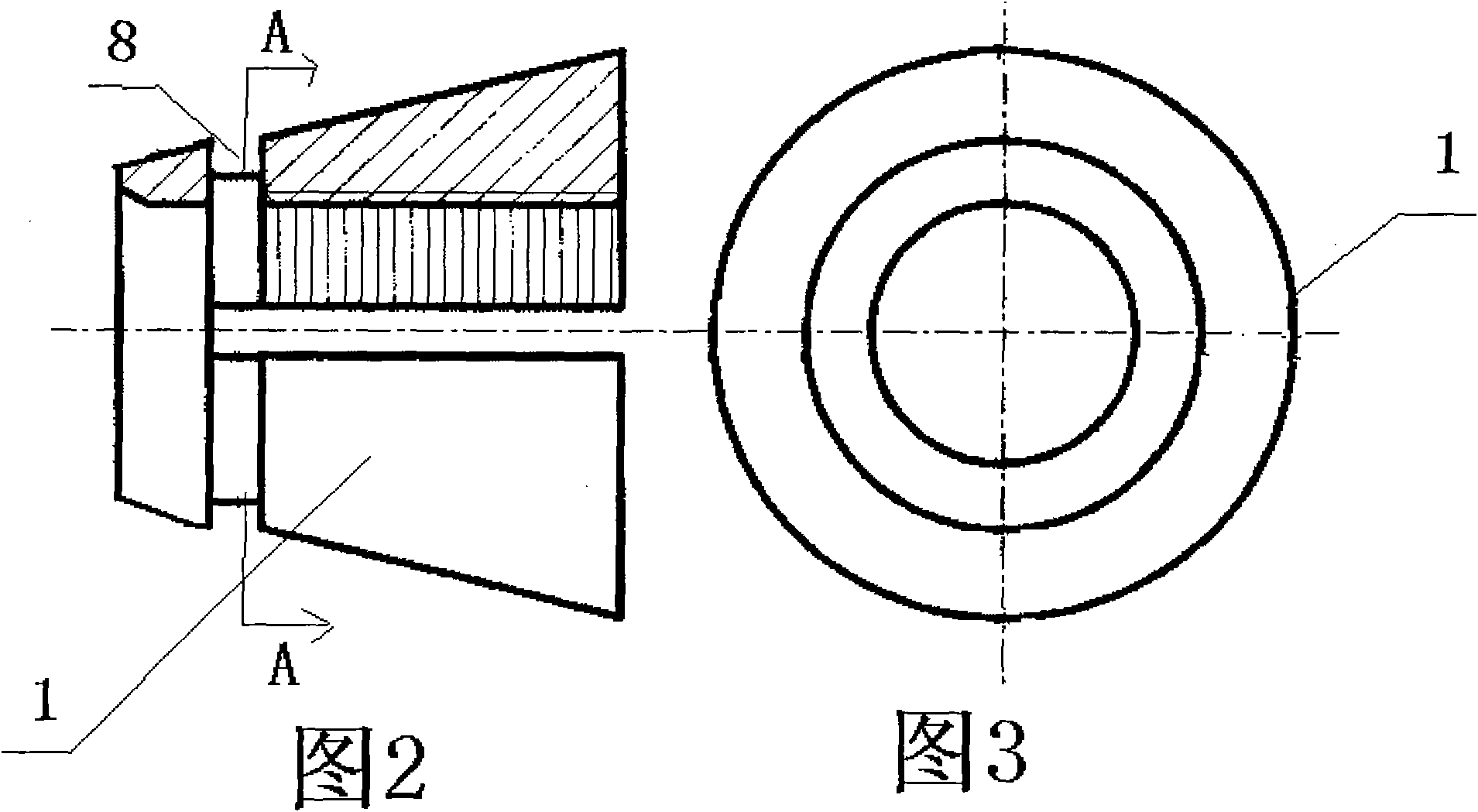

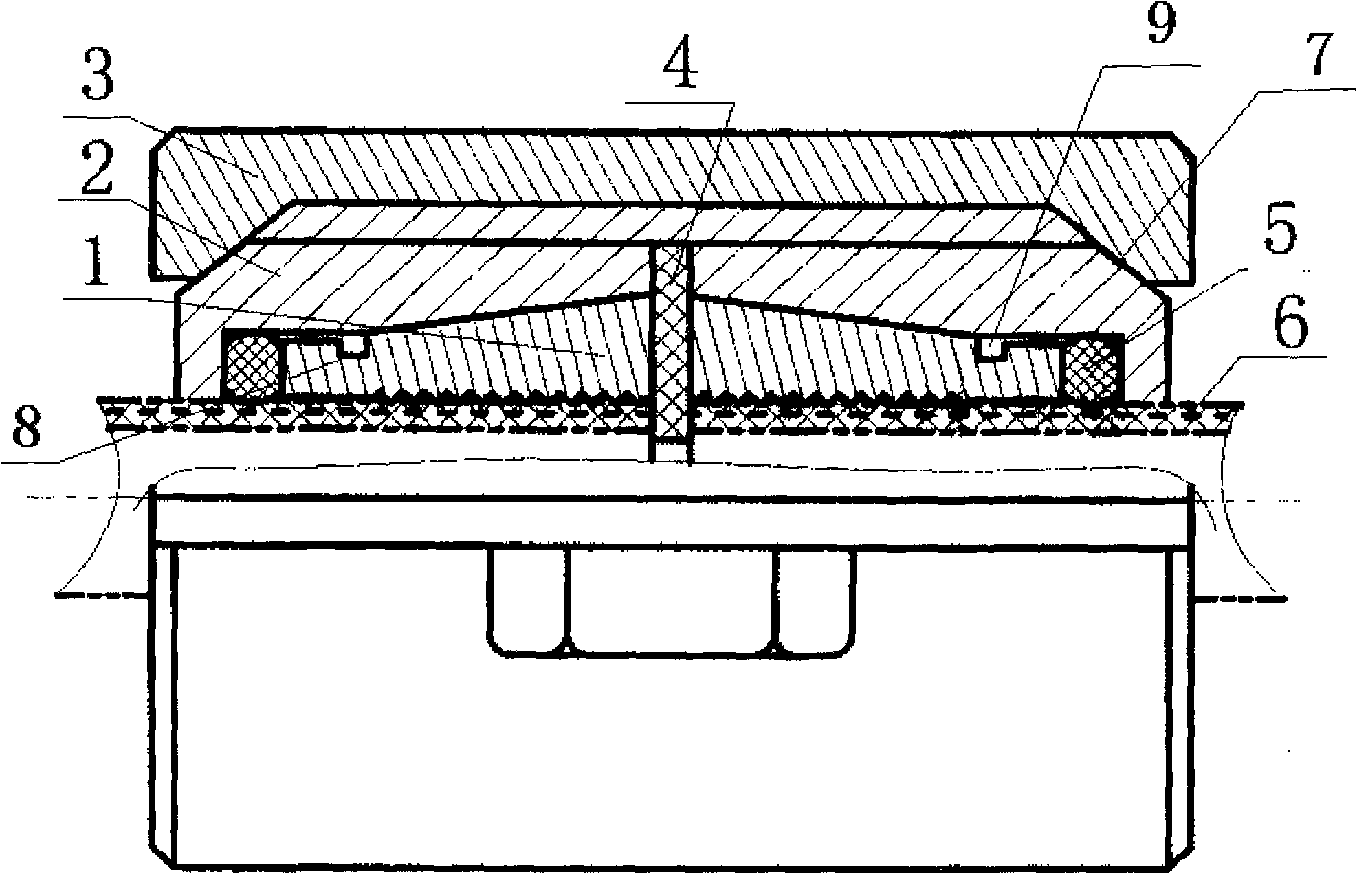

[0014] Example: such as figure 1 , figure 2 , image 3 As shown, a pipe quick-repair clamp sleeve joint, including claw 1, locking sleeve 2, clamping member 3, sealing gasket 4, sealing ring 5, the two sealing rings 5 and a pair of tapered The claws 1 are respectively set on the nozzles of the connected pipes 6, and are set in the tapered hole of the locking sleeve 2. The taper of the outer tapered surface of the claw 1 matches the taper of the tapered hole of the locking sleeve 2. , the outer tapered surface of the pair of tapered claws is provided with an annular groove 8, the inner tapered surface of the locking sleeve is provided with a matching protrusion 9, and the inner tapered surface of the claw 1 The holes match the outer diameters of the connected pipes 6, the sealing pad 4 is arranged at the butt joint of the two connected pipes 6 and is clamped by a pair of claws 1, and the clamping member 3 Installed on the locking sleeve 2, the outer shape of the locking slee

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap