Driving circuit of optoelectronic equipment and driving method thereof

A technology of optoelectronic equipment and driving circuits, which is applied in the electronic field, can solve the problems that I/O ports cannot complete control tasks, and cannot reduce the occupation of single-chip I/O ports, etc., and achieve the effects of improving reliability, reducing occupancy, and simplifying circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

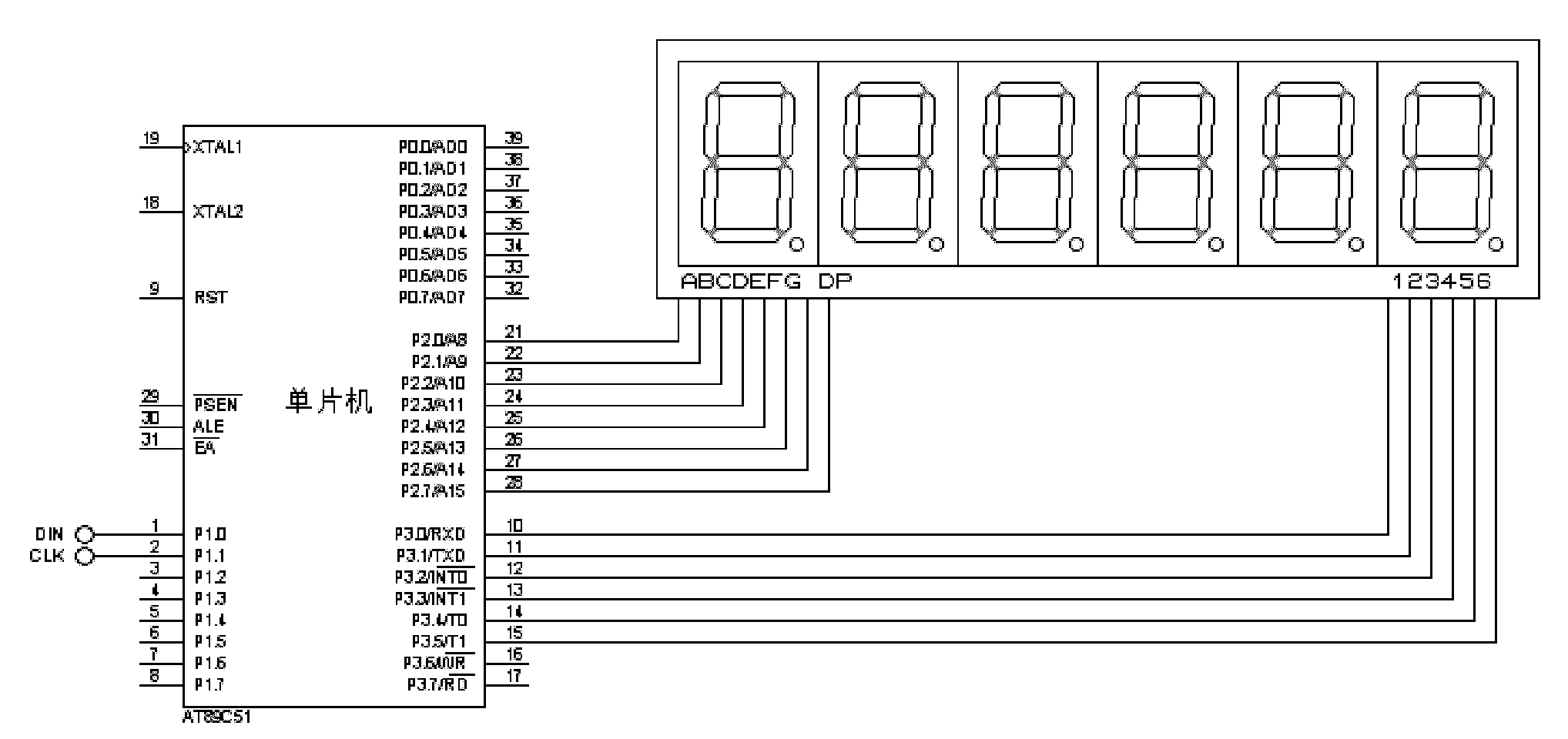

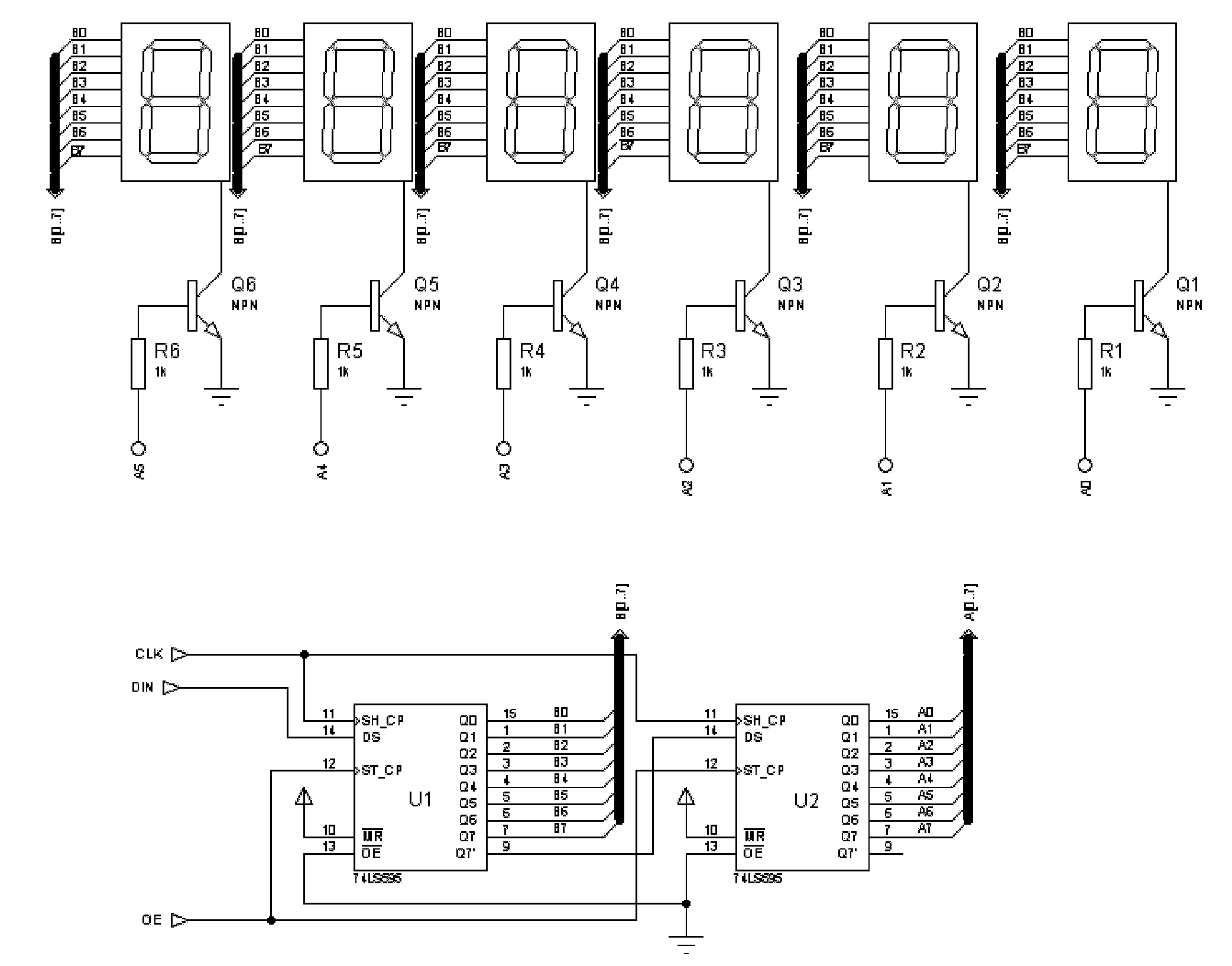

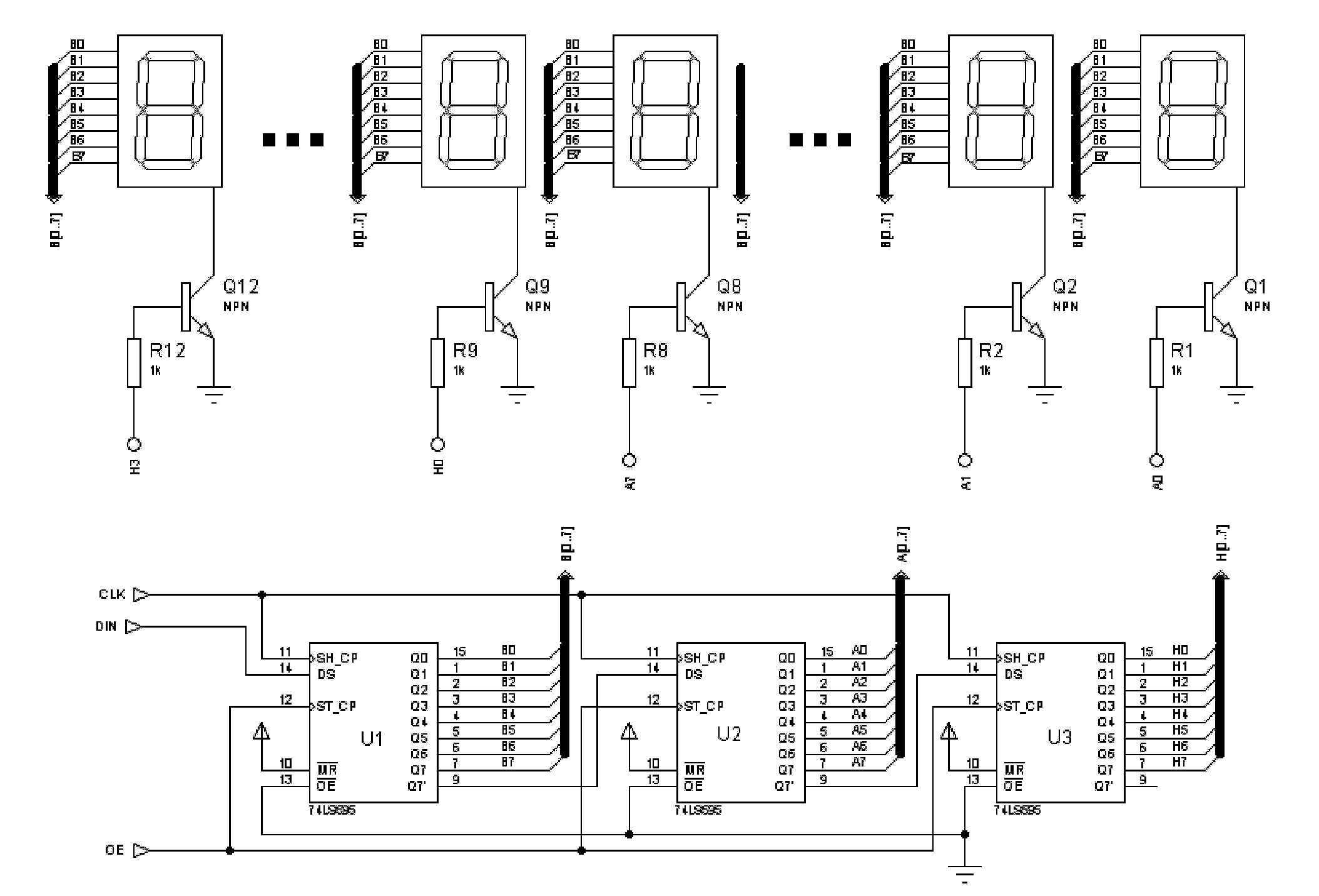

[0023] The invention connects a plurality of serial-to-parallel conversion chips between the single-chip microcomputer and the nixie tube, completes the conversion of data serial-in and parallel-out through the serial-to-parallel conversion chips, and realizes only using three-terminal bus to control and drive the photoelectric equipment.

[0024] figure 2 The driving circuit diagram of the six digital tubes provided for the first embodiment of the present invention only shows the parts related to the present invention for the convenience of description.

[0025] In this embodiment, the drive circui

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap