Electronic fuel injection (EFI) rapid electromagnet

A fuel injection and electromagnet technology, which is applied in fuel injection devices, electromagnets with armatures, electromagnets, etc., can solve the problems of insufficient attention to the release process of the electromagnet, the influence of the response speed of the electromagnet, and stickiness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

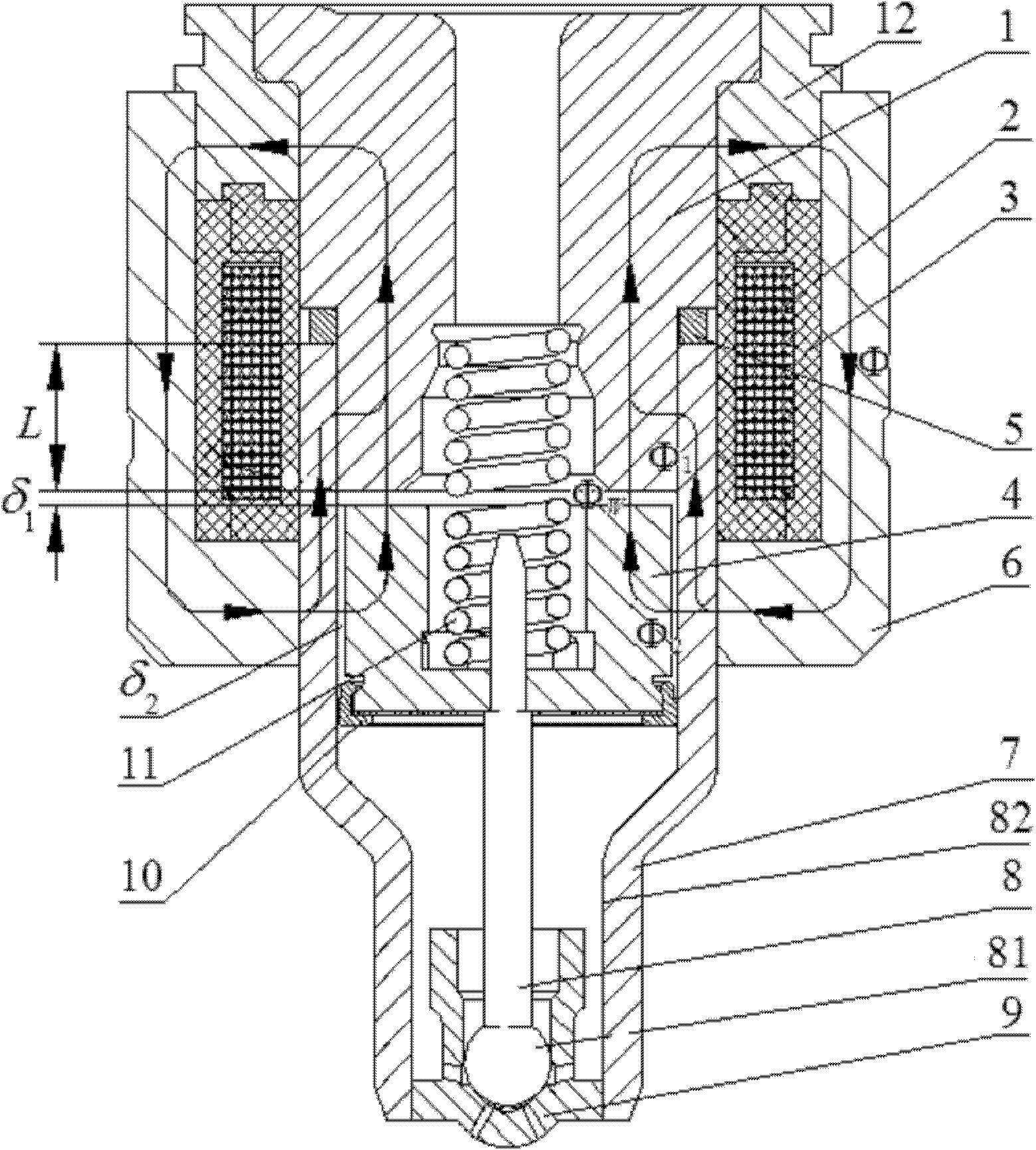

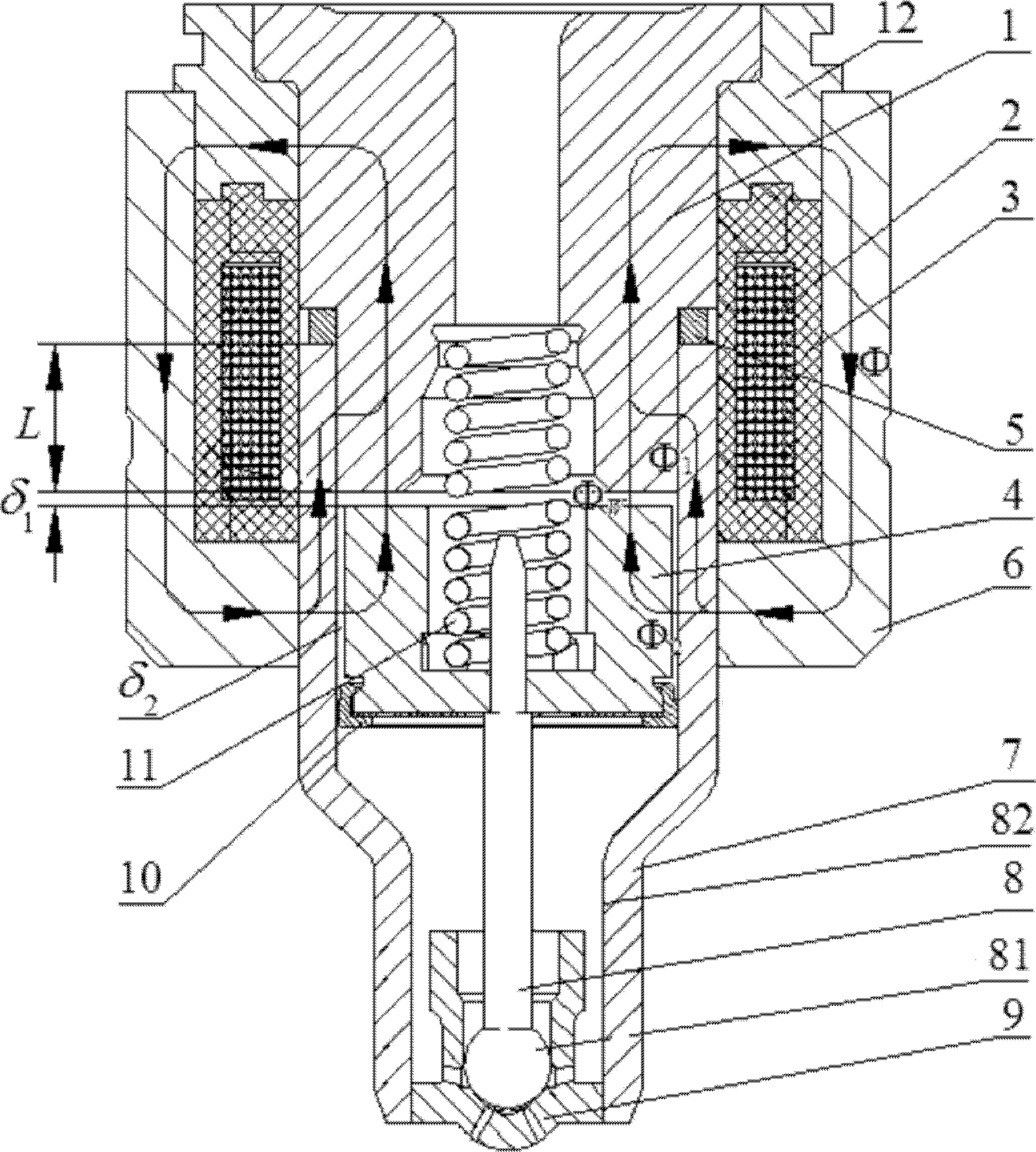

[0009] refer to figure 1 . It is mainly composed of iron core 1, coil 2, coil skeleton 3, armature 4, magnetic isolation ring 5, outer shell 6, inner shell 7, valve stem 8, valve seat 9, armature accessories 10, valve stem spring 11 and The intermediate housing 12 is formed. They are assembled together as shown to form an electronically controlled fuel injection fast solenoid assembly.

[0010] The magnetic isolation ring 5 and the inner casing 7 are assembled on the lower stepped axial end surface of the iron core 1 , and the magnetic isolation ring 5 is located between the lower stepped end surface of the iron core 1 and the inner casing 7 opening end surface. The coil 2 surrounding the stepped cylinder of the iron core 1 through the bobbin 3 is closely attached to the upper cylindrical surface of the inner casing 7 . The coil bobbin 3 is positioned in the annular slot on the lower end surface of the intermediate housing 12 and assembled in the cylinder of the outer housing

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap