Cross-shaped linking plate for ultra-high voltage (UHV) transmission line

A transmission line, cross-shaped technology, applied in the direction of the suspension device of the cable, etc., can solve the problems of shortening the length of the hardware string and unbalanced force, and achieve the effect of improving the distribution of the electric field, lowering the use cost and reducing the investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with example the present invention is described in detail.

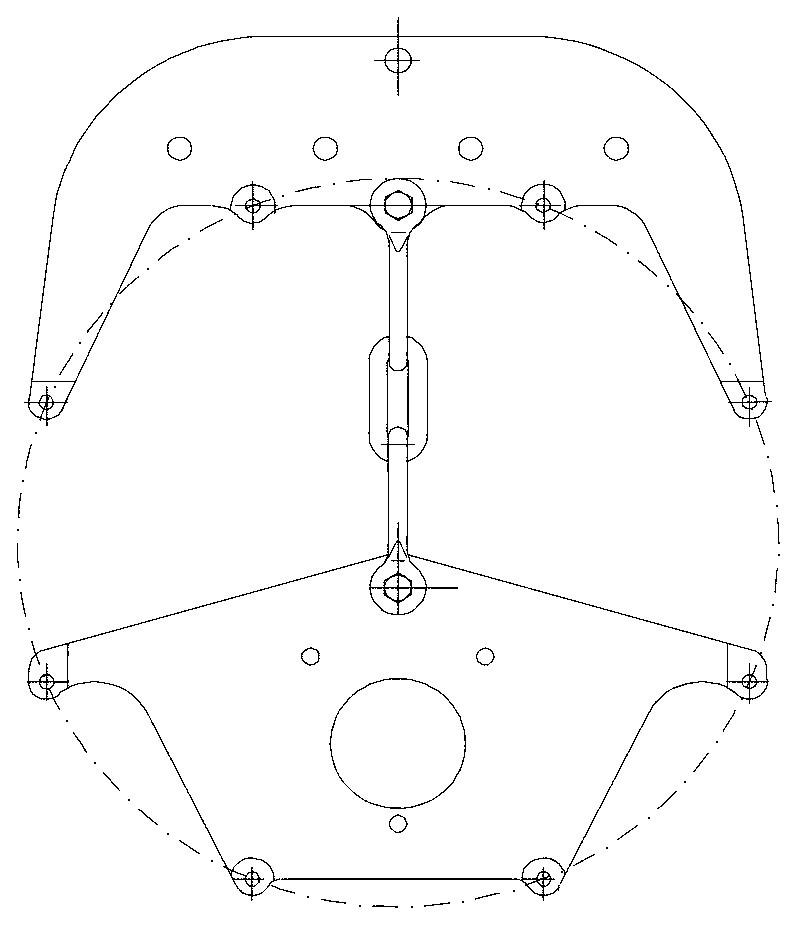

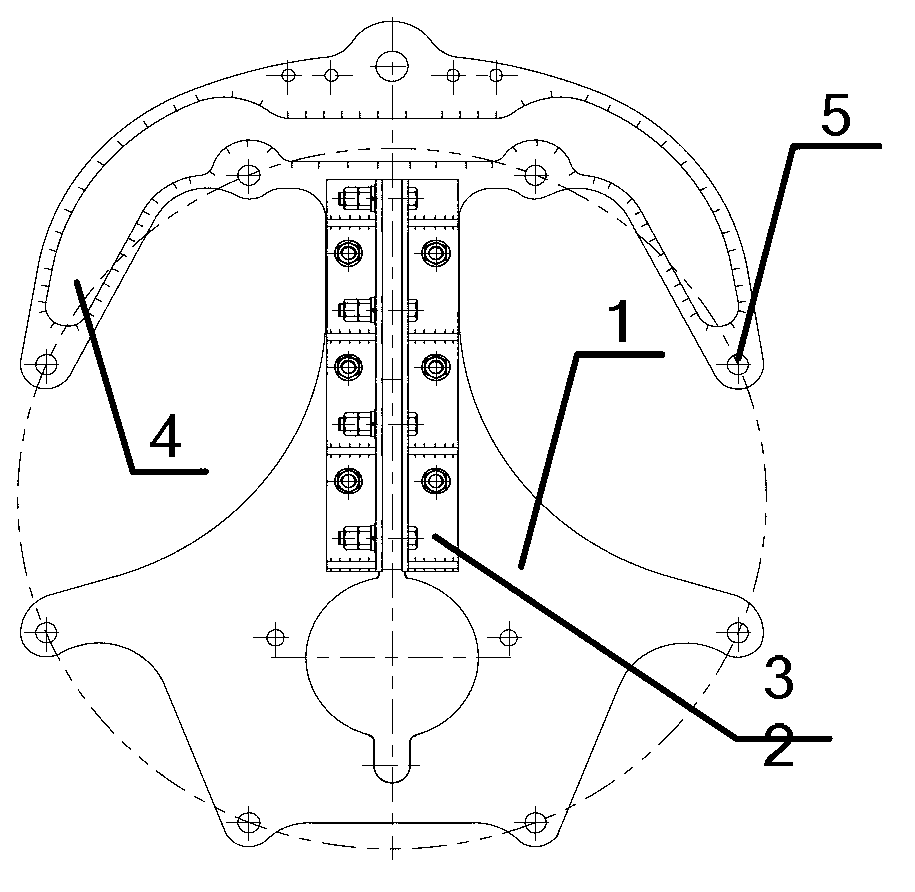

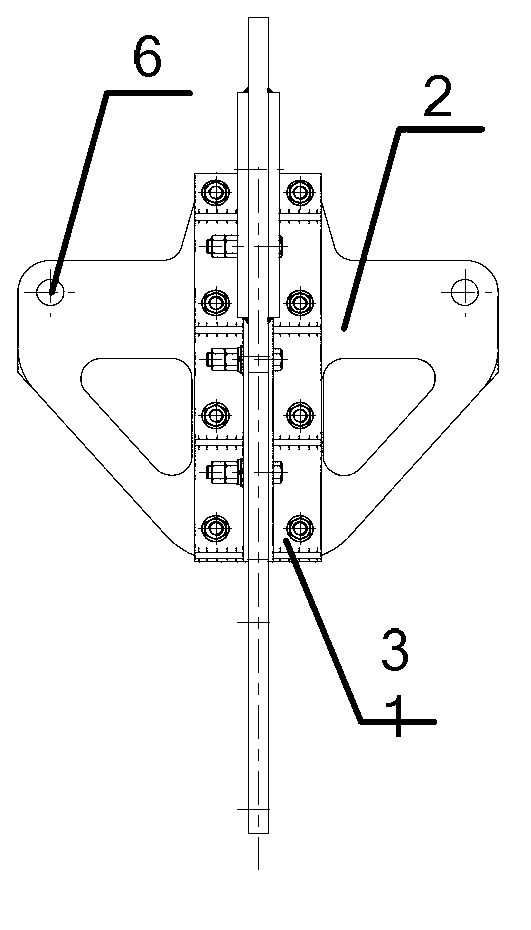

[0045] The cross-shaped connecting plate structure developed by the patent of the present invention is quite different from the split-type hanging connecting plate used on the current transmission line. The hanging holes 5 are evenly distributed on the large plate 1. There are two connection holes between the insulator string and the hanging connecting plate, which are respectively located at the two ends of the small plate 2 . Compared with the common eight-split suspension connecting board, the hanging hole 6 of the insulator in the cross connecting board is located inside the wire splitting circle, and the connecting line of the two hanging string holes 6 is parallel to the wire.

[0046] The cross joint plate structure developed by the patent of the present invention, its main part-two joint plates of large and small sizes are connected vertically by bolts, that is, the two joint plates

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap