More reliable seat suspension mechanism

A seat, a reliable technology, applied in the direction of the seat suspension device, etc., can solve the problems of shaking, insufficient suspension, etc., and achieve the effect of no shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

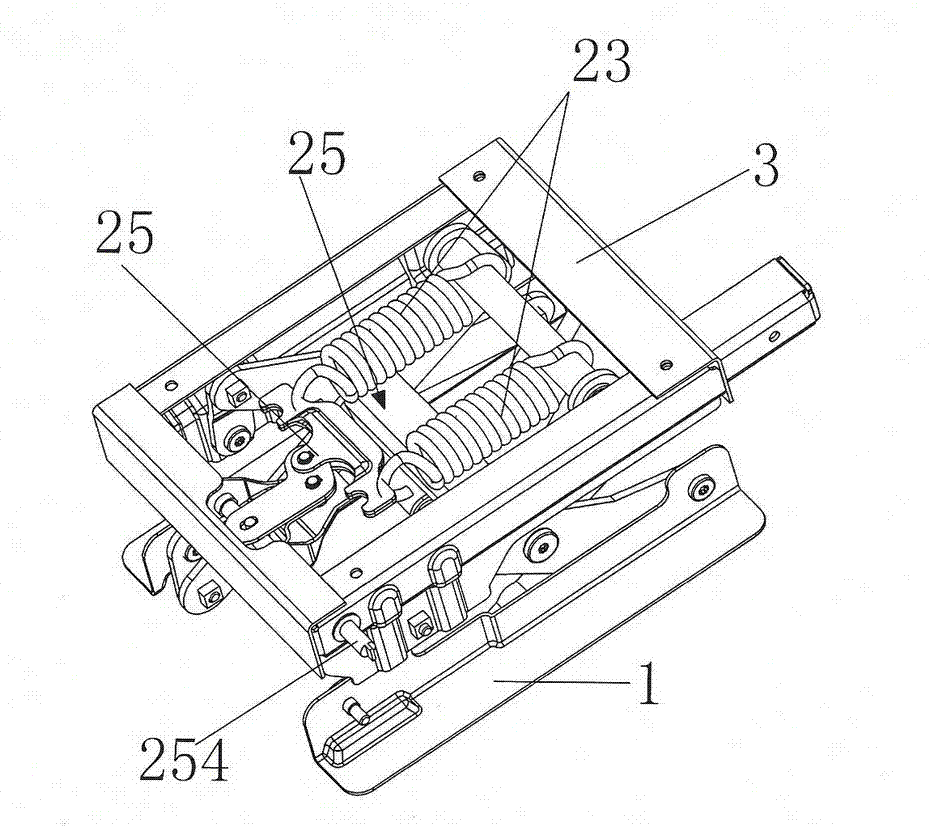

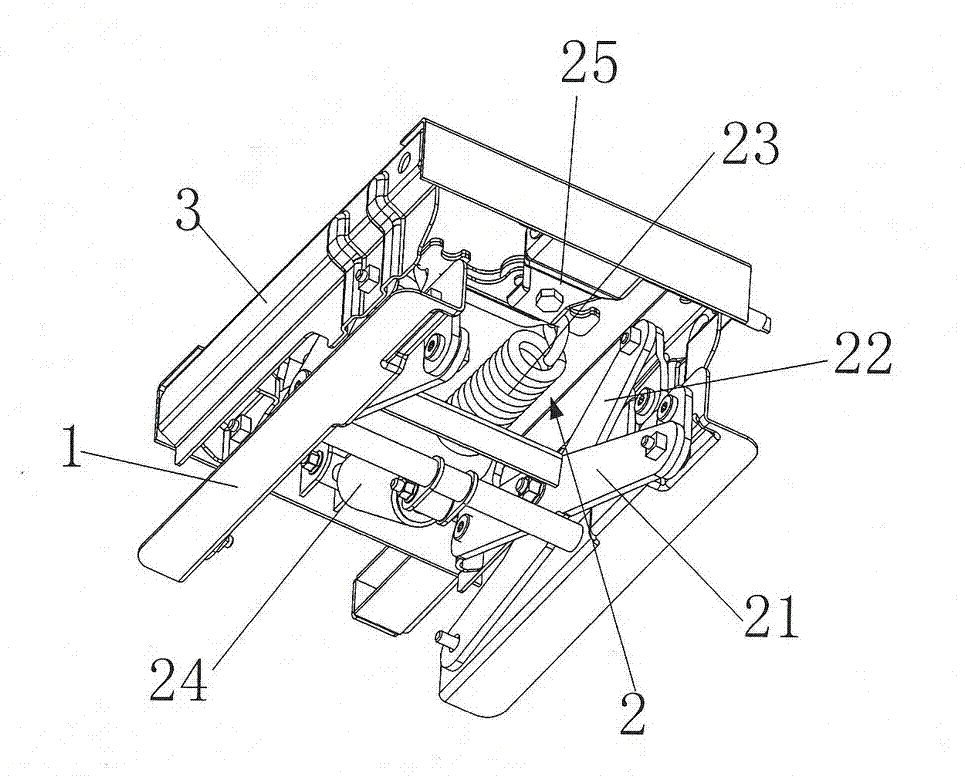

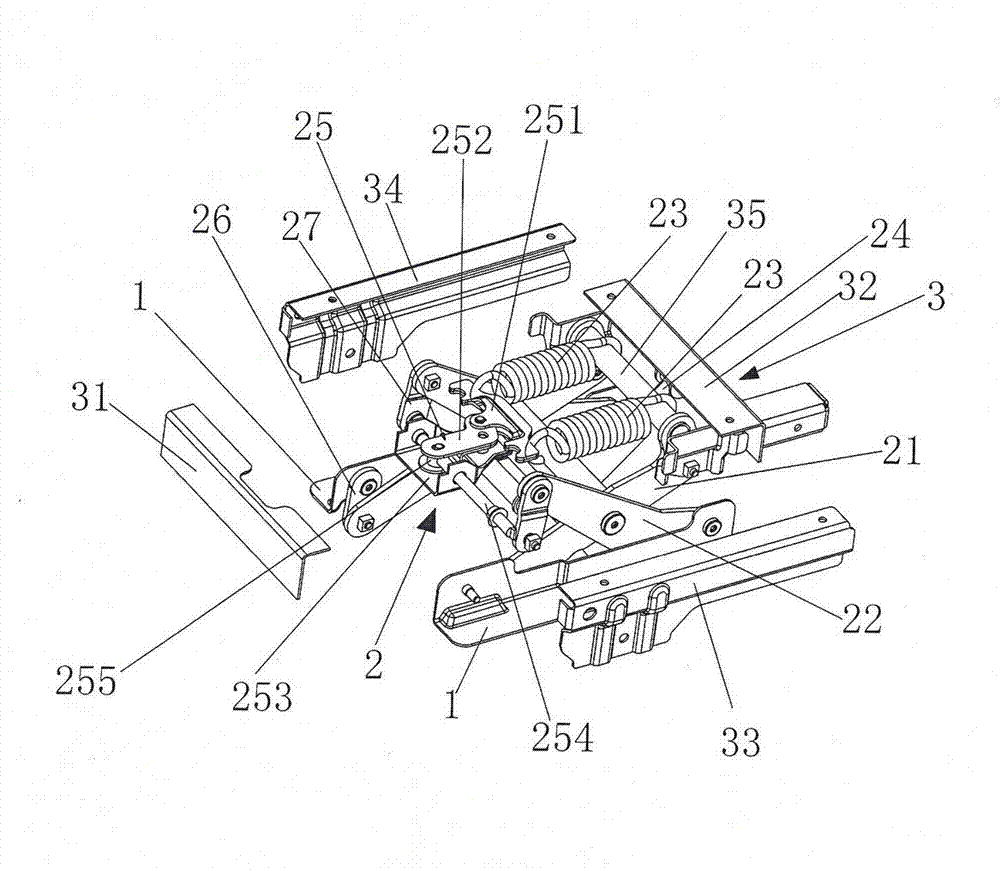

[0009] See figure 1 , figure 2 with image 3 As shown, this embodiment is composed of a lower frame 1, a stiffness adjustment device 2 and an upper frame 3. The stiffness adjustment device 2 is located between the lower frame 1 and the upper frame 3, and the stiffness adjustment device 2 is composed of an inner bracket 21 and an outer bracket 22 , Two springs 23, a damper 24 and a stiffness adjustment assembly 25. The upper frame 3 is composed of a front frame 31, a rear frame 32, a left frame 33 and a right frame 34. The inner bracket 21 and the outer bracket 22 form an internal scissor mechanism , The upper end of the inner bracket 21 is hinged with the two sides of the rear frame 32, the two lower ends of the inner bracket 21 are hinged with the two first connecting rods 26, and the other end of the first connecting rod 26 is hinged with the lower frame 1. The two lower ends of the outer bracket 22 are hinged to the lower frame 1 respectively, the two upper ends of the outer b

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap