Quantifying device used for outputting powder or granular material

A technology of granular material and quantitative device, applied in applications, household appliances, kitchen utensils, etc., can solve the problems of difficulty in accurately grasping the amount of seasonings poured, inconvenient and quantitative pouring of seasonings, and endangering health, etc., and achieve convenient and accurate quantitative control. output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

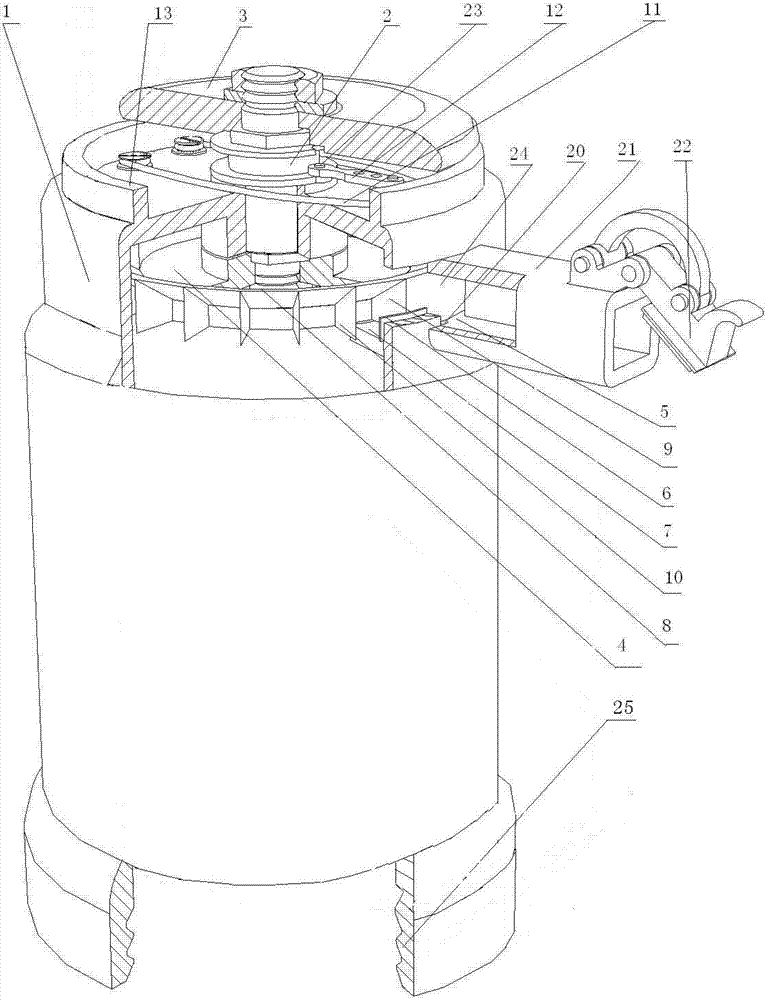

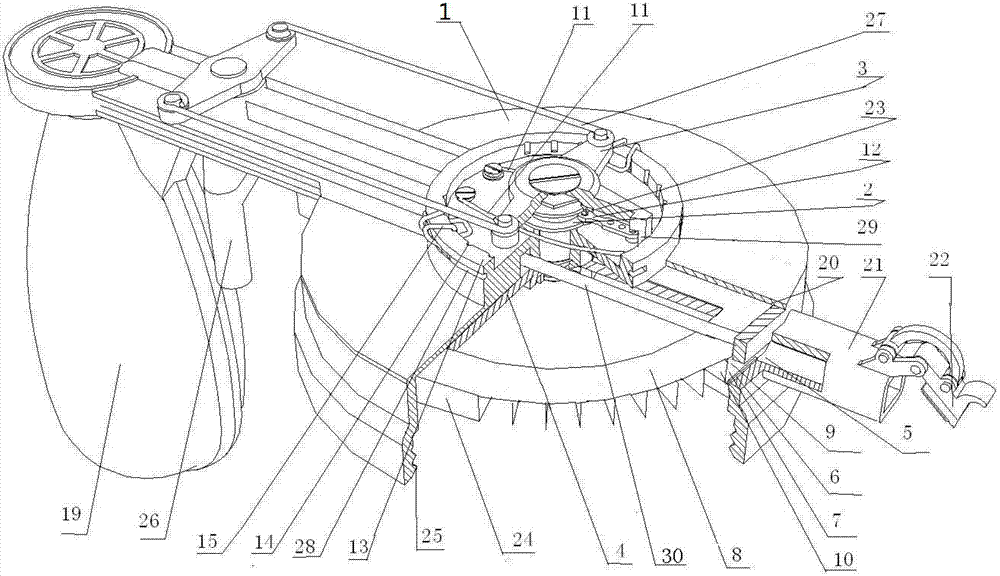

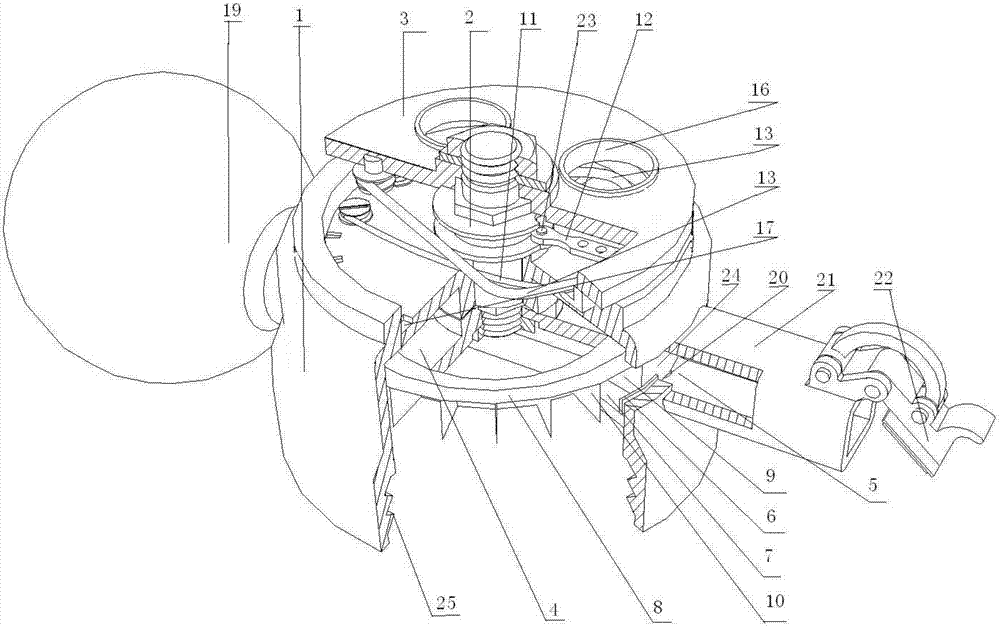

[0021] Attached below figure 1 and 6 A first embodiment of the present invention will be described.

[0022] A quantitative device for outputting powder or granular materials has a cylindrical shell 1 integrated on the upper end of a bottle cap, and an internal thread 25 is formed on the lower end of the bottle cap. The center of the cylindrical housing 1 is equipped with a linkage shaft 2, the upper end of the linkage shaft 2 is fixed with a dial 3, and the lower end is fixed with a quantitative disk 4, and the dial 3 is located on the upper surface of the housing 1, and the quantitative disk 4 is located in the housing 1; the right side of the cylindrical housing 1 is shaped on a discharge opening 5, a limiting wall 6 and a fan-shaped limiting bottom plate 7, and the discharge opening 5 is located above the middle right side of the fan-shaped limiting bottom plate 6, and the limiting The wall 6 is symmetrically located on both sides of the discharge port 5, and the quantitati

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap