Capping type antiknock anti-loose pipe nut

A technology for compressing nuts and nuts, applied in the direction of nuts, screws, bolts, etc., can solve the problems of complex manufacturing process, difficult control of eccentric cone surface processing, etc., and achieve the effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

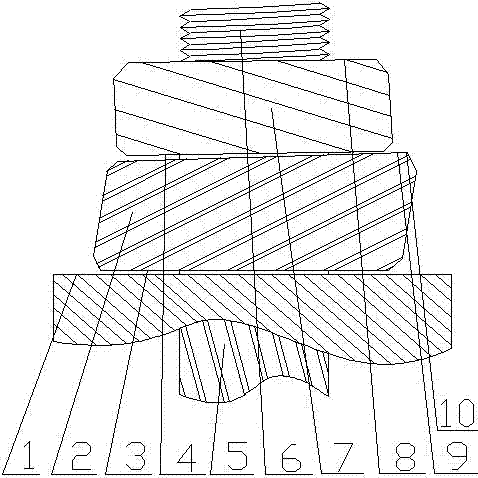

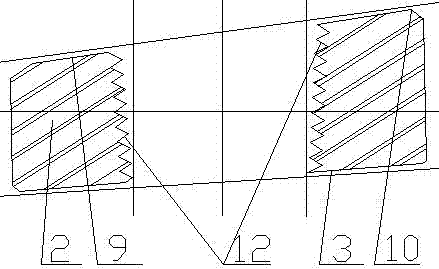

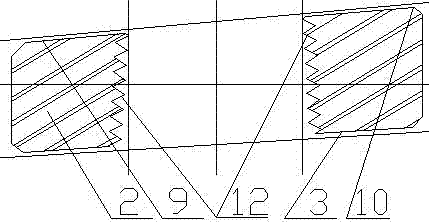

[0029] exist figure 1 In the embodiment shown in —9: the top-pressing anti-seismic anti-loosening pipe nut includes a compression nut 2 that is in contact with the pressed surface 1 of the nut and a backup nut 7 that is pressed on the compression nut 2; The compression nut 2 is a hexagonal nut, and its internal thread is a pipe thread structure with one end slightly larger and the other end slightly smaller. Both the compression nut compression surface 3 and the compression nut upper end surface 9 are not parallel to the vertical line of the central axis of the compression nut 2 But the direction of inclination is exactly the same, and the angle between the upper end face 9 of the compression nut and the vertical line of the central axis of the compression nut 2 is larger than the angle between the vertical line of the central axis of the compression nut compression surface 3 and the compression nut 2, that is, the angle of the vertical line of the central axis of the compression

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap