Filtering assembly used for connector and coil winding method

A technology of filtering components and winding methods, which is applied in the direction of coil manufacturing, transformer/inductor coil/winding/connection, electrical components, etc., can solve the problems that cannot meet the increasingly high-speed transmission requirements, improve the quality of life and work, and speed up The pace of high-speed development and the effect of meeting the needs of high-speed transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

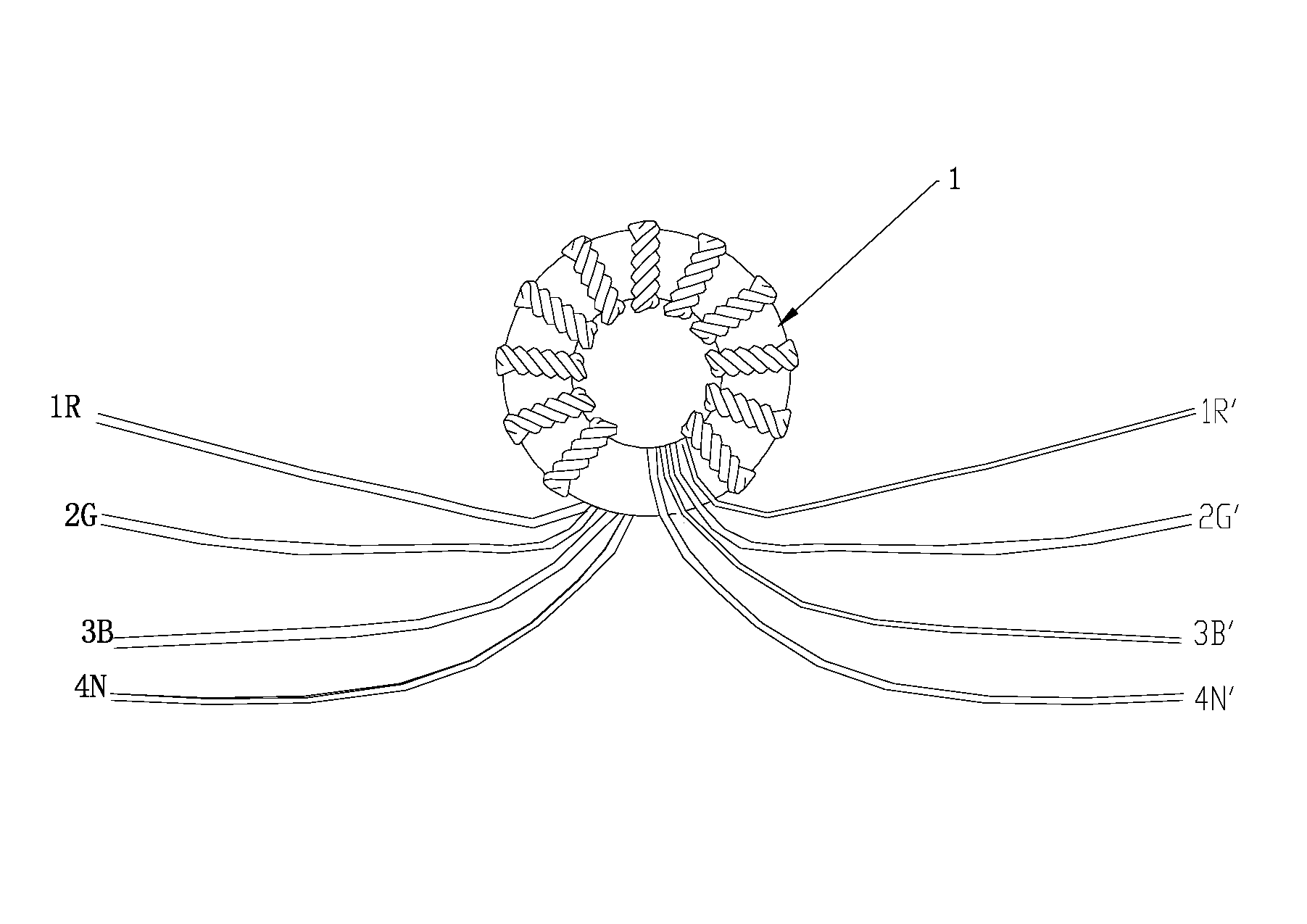

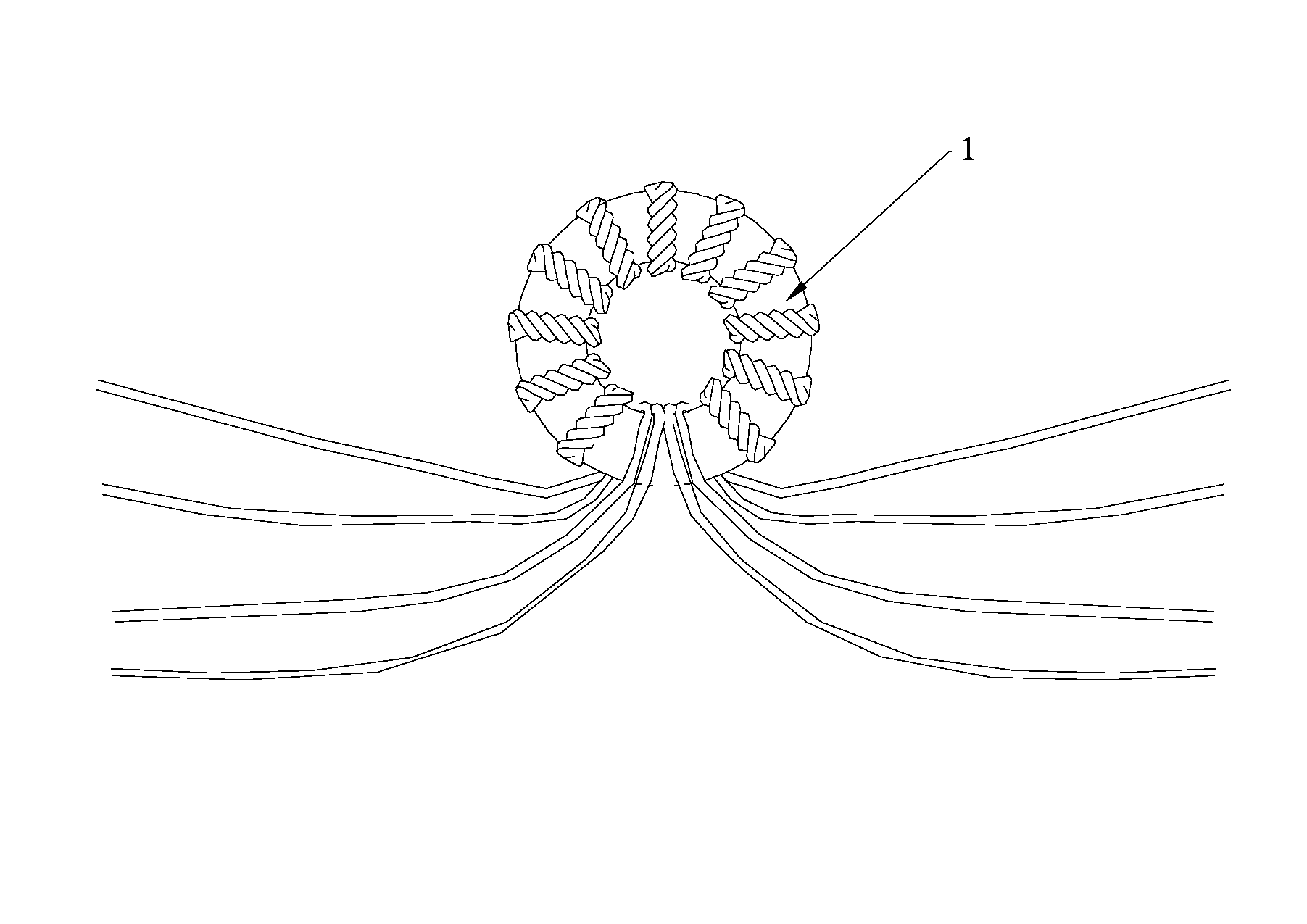

[0058] Please refer to Figure 5 to Figure 12 As shown, the plurality of metal wires used in the implementation of the present invention are three-wire metal wires. A filter assembly for a connector, comprising at least one coil wound with three-wire metal wires and leaving a wire end, each coil contains at least one magnetic element 1, and the hollow of each magnetic element 1 forms a perforation, the magnetic element 1 Surrounded by two three-wire metal wires, the two three-wire metal wires respectively pass through the hollow perforation of the magnetic element 1 and surround the magnetic element 1 in a circular manner, and the beginning and end ends of the two three-wire metal wires are set as The wire ends, wherein the start end wire ends and the end wire ends of the two complex metal wires are respectively located on both sides of the hollow perforation of the magnetic element 1, and a fixed gap 12 is arranged between the start end wire ends and the end wire ends of the two

Embodiment 2

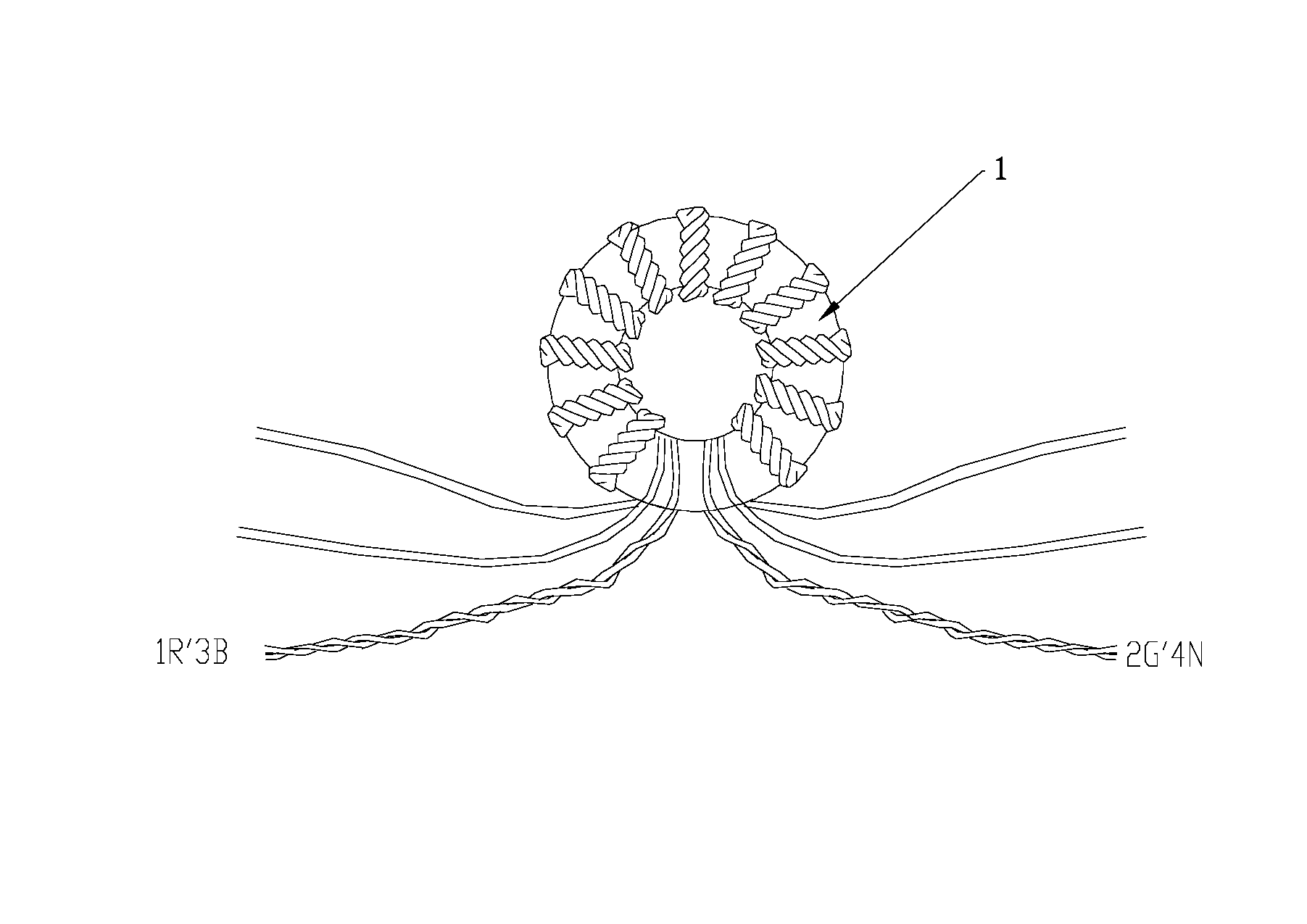

[0065] Please refer to Figure 13 to Figure 20 The difference between this embodiment and the first embodiment lies in that the multiple metal wires in the present invention are four-wire metal wires.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap