Generator rotor coil winding mechanism

A technology of generator rotor and winding mechanism, which is used in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of large winding force, palm damage, and difficulty in ensuring winding quality, and achieves obvious compaction effect. Reduced friction loss, easy industrial application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

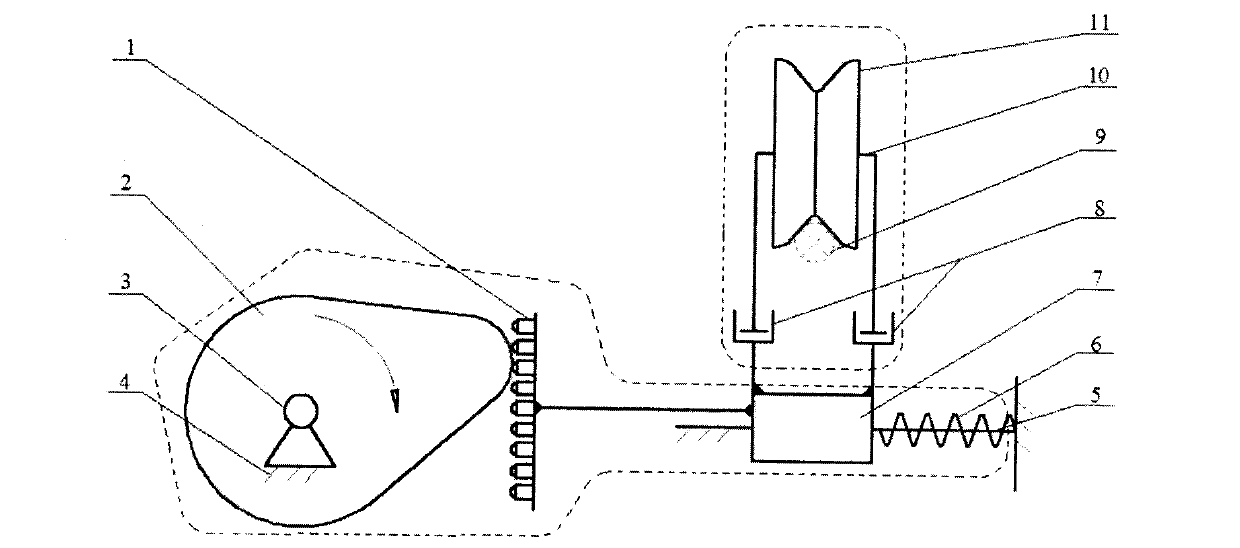

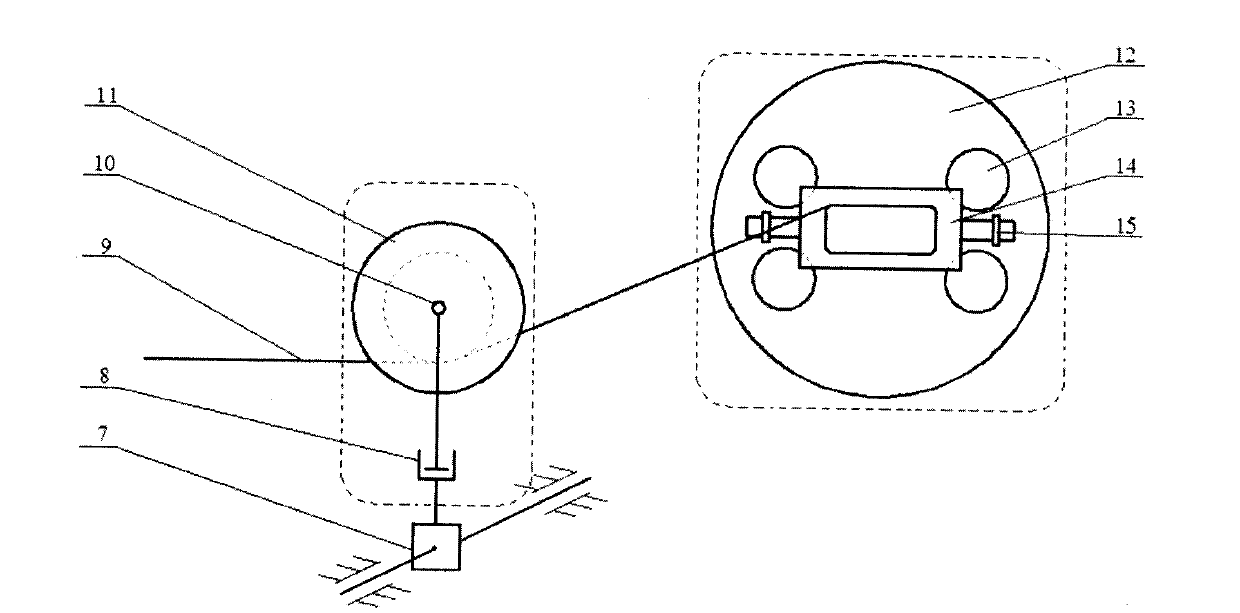

[0017] The present invention will be further described in detail below in conjunction with the drawings.

[0018] The present invention is a generator rotor coil winding mechanism, which includes a moving guide device, a wire pressing device and a rotor clamping device. The rotary drive 3 is fixed on the frame 4 to drive the cam 2 to rotate eccentrically, and the cam 2 is pressed against the contact roller set 1 Tight and rolling contact, the contact roller set 1 and the sliding block 7 are fixedly connected, the sliding block 7 can be directionally moved with a single degree of freedom on the slide rail 5 fixed to the frame 4, and the two ends of the return spring 6 are respectively connected with the sliding block 7 and the frame 4Fixed connection. One end of two symmetrically distributed gas springs 8 is fixedly connected to the slider 7, and the other end respectively supports the two ends of the central shaft 10, the concave wheel 11 passes through the central shaft 10, and the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap