Three-dimensional soft model cutting forming machine and method

A molding machine and soft technology, applied in molding/shaping machines, special molding/shaping machines, large fixed members, etc., to achieve the effects of smooth and fast processing, high compactness, and small equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

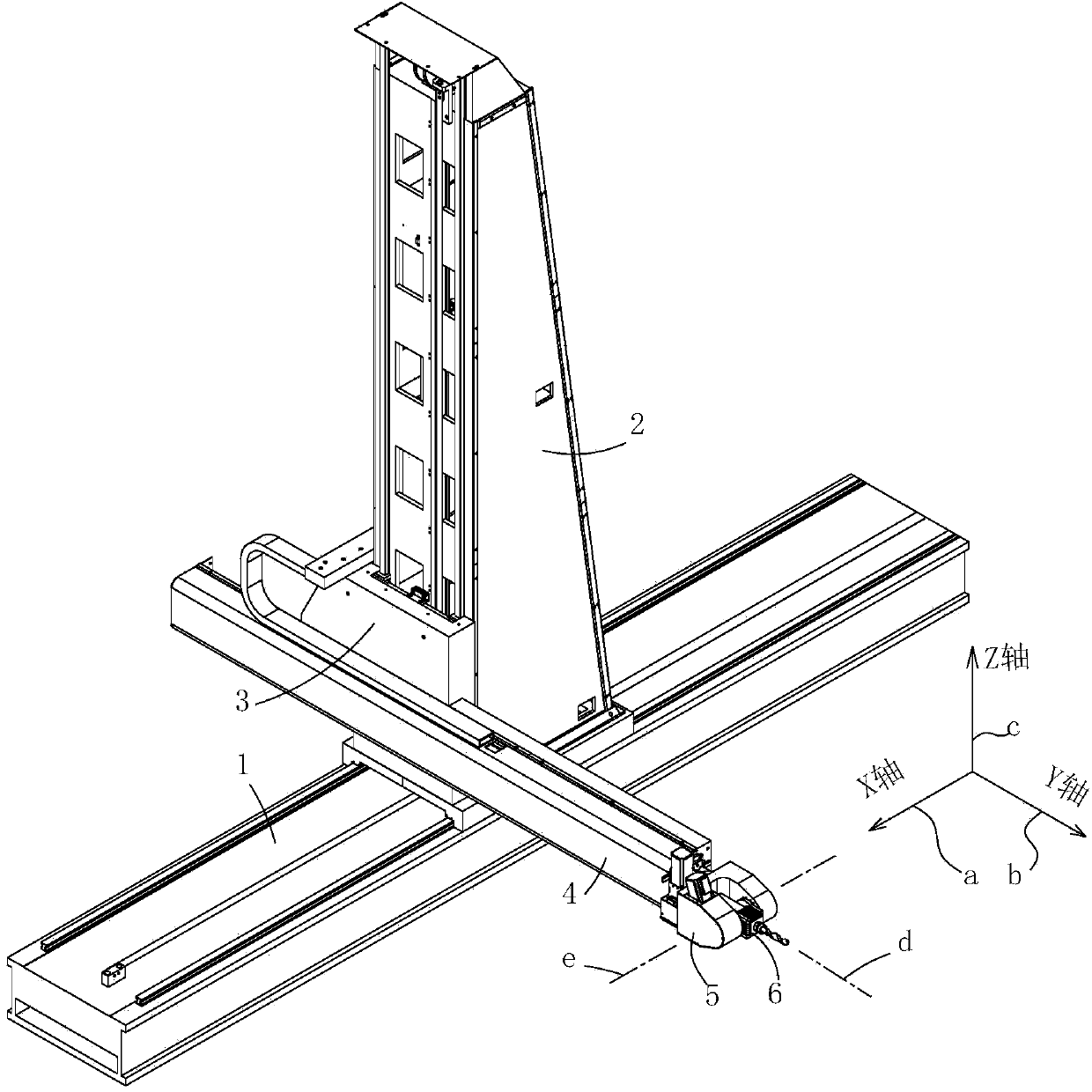

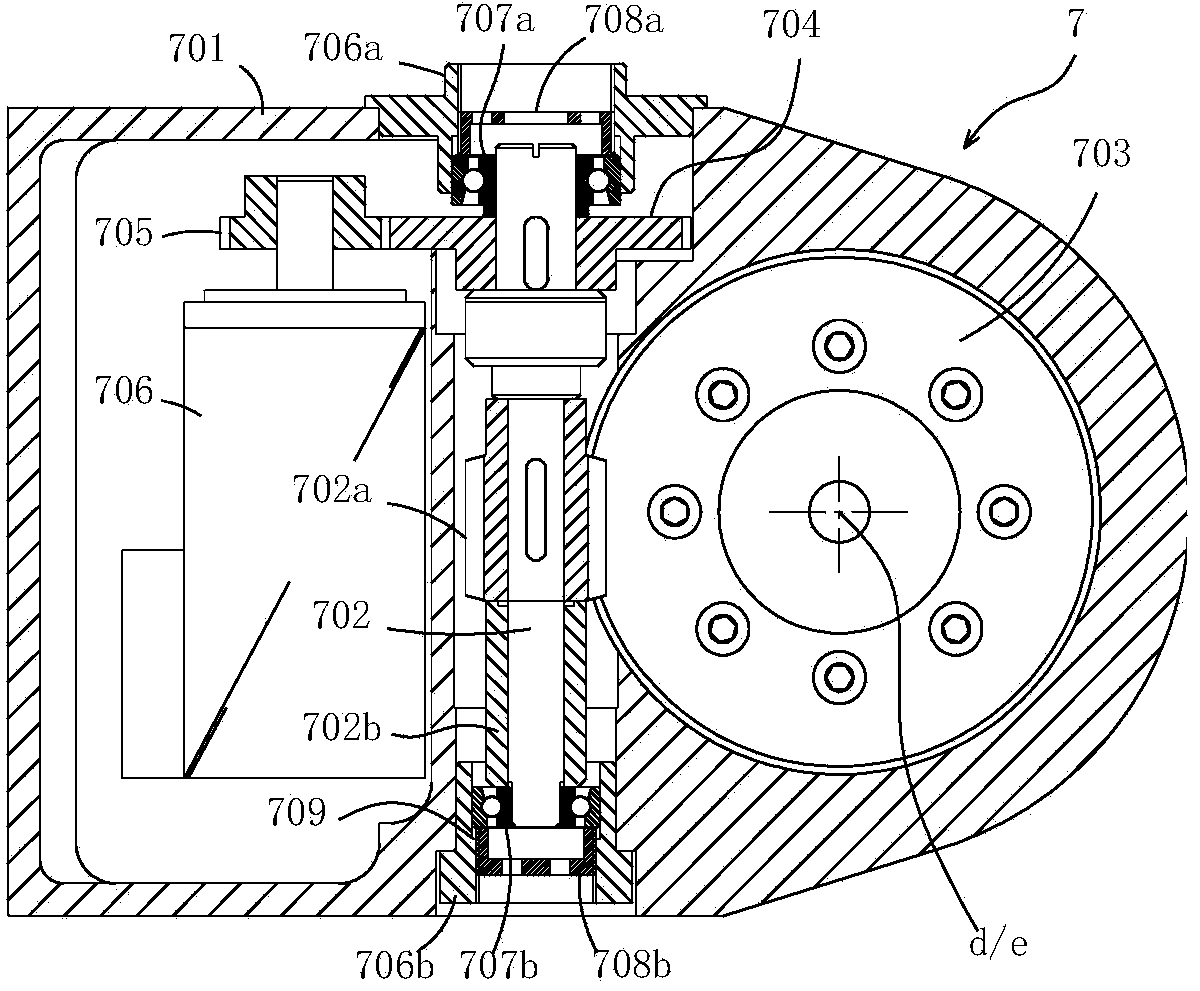

[0027] Such as figure 1 As shown, the three-dimensional soft model cutting and forming machine includes: a base 1; a column 2, the column 2 is installed on the base 1 through the first guiding driving mechanism and can reciprocate along the horizontal X-axis a under the support of the first guiding driving mechanism ; fixed cantilever 3, said fixed cantilever 3 is installed on the column 2 by the second guide drive mechanism and can reciprocate along the vertical Z-axis c under the maintenance of the second guide drive mechanism; movable cantilever 4, said movable cantilever 4 is installed on the fixed cantilever 3 through the third guide drive mechanism and can reciprocate along the horizontal Y-axis b under the support of the third guide drive mechanism; the angle milling head base 5, the angle milling head base 5 passes through the fourth guide The driving mechanism is installed on the front end of the movable cantilever 4 and can swing bidirectionally around the first referen

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap