Silencer for supercharger, and supercharger and hybrid supercharger each comprising same

A silencer and supercharger technology, which is applied to machines/engines, parts of pumping devices for elastic fluids, mechanical equipment, etc., can solve problems such as costing a lot of manpower and time, and achieve simplification of maintenance operations and improvement maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, a hybrid supercharger including a muffler according to the present embodiment will be described in comparison with a conventional hybrid supercharger including a muffler with reference to the drawings.

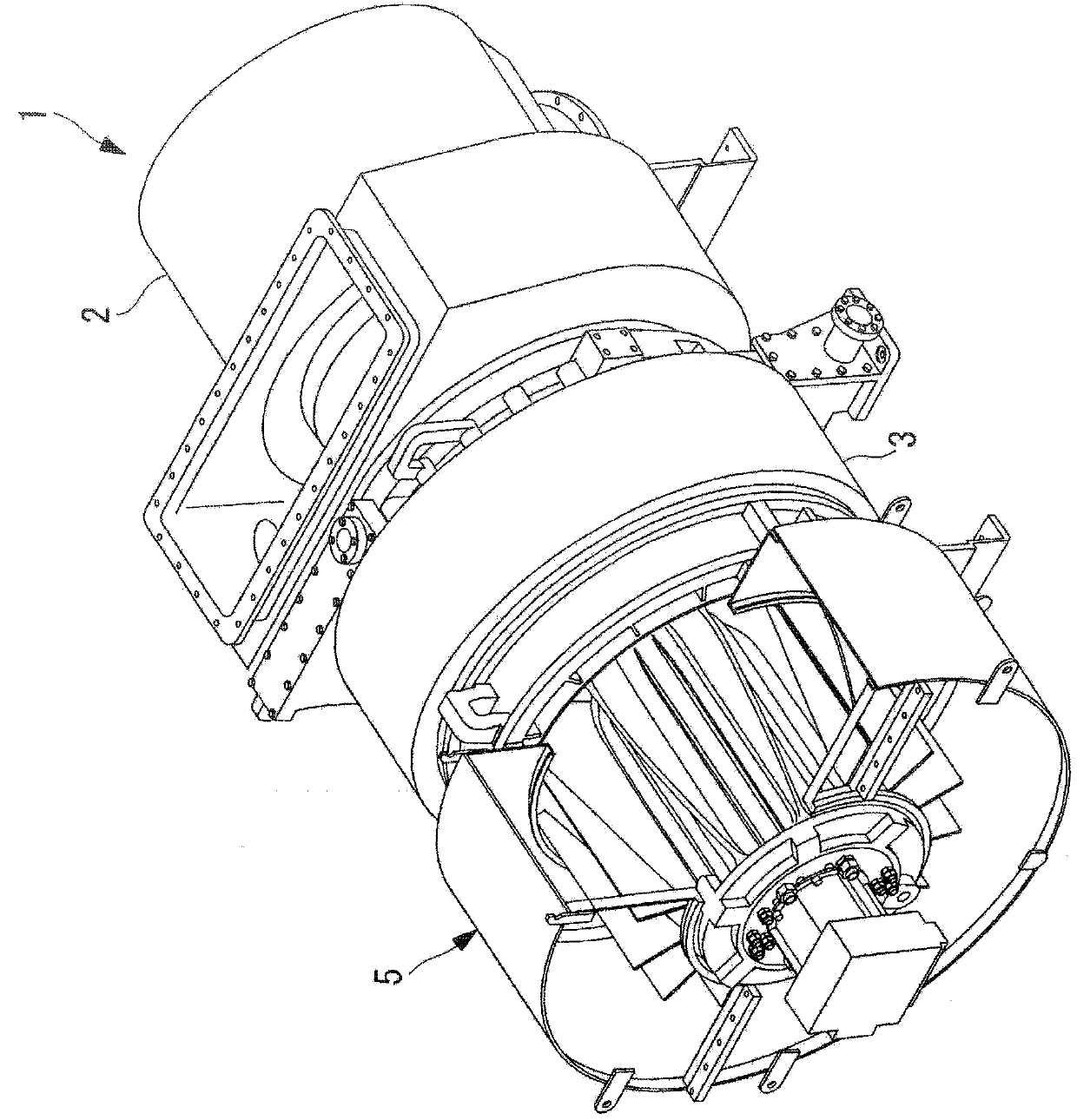

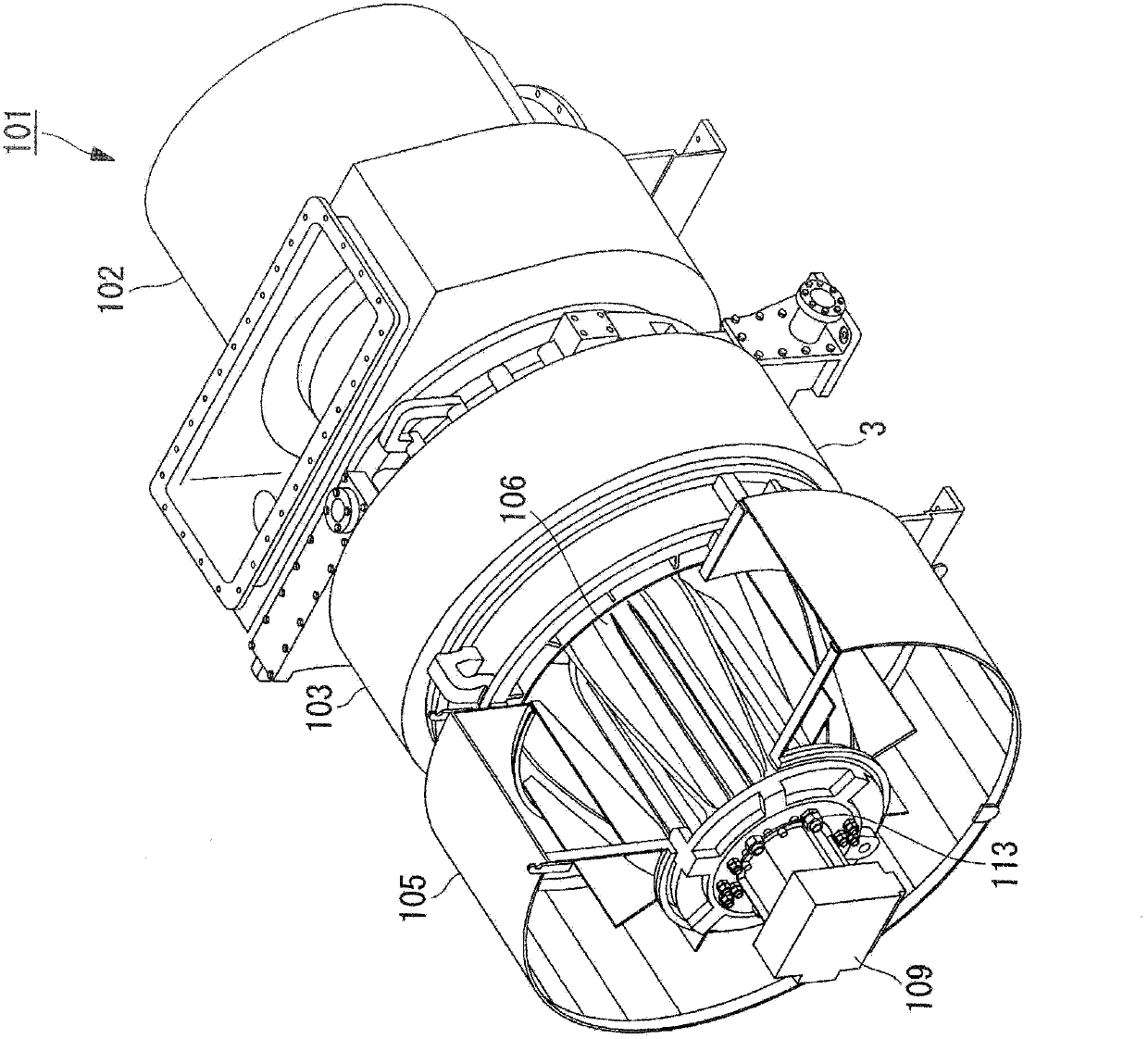

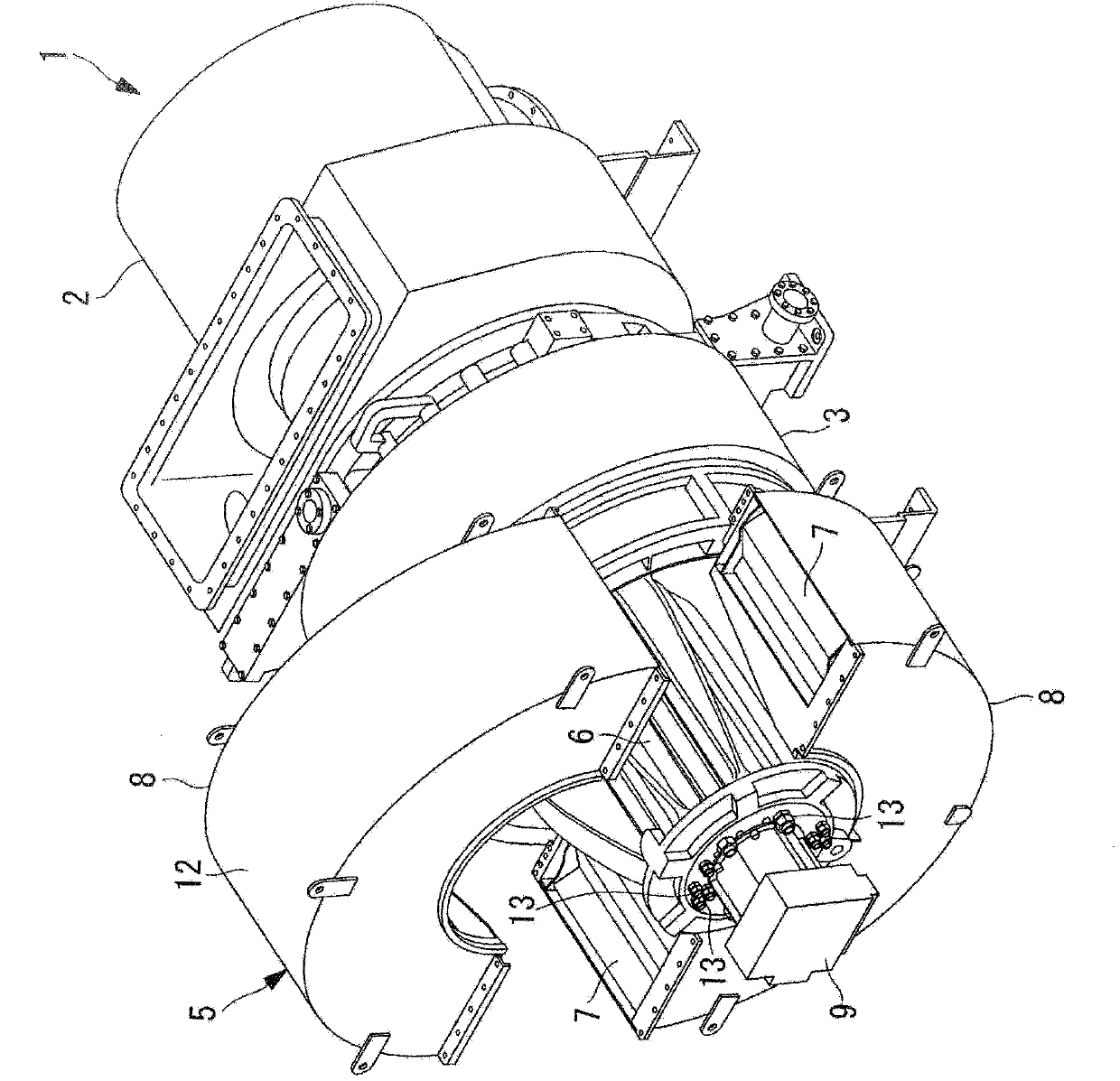

[0057] figure 1 shows a perspective view of a hybrid supercharger equipped with a muffler according to this embodiment, figure 2 A perspective view of a hybrid supercharger equipped with a conventional muffler is shown in . also, Figure 3 to Figure 5 show figure 1 The shown perspective view and partially enlarged structural view of the muffler according to the present embodiment. Furthermore, FIGS. 6 to 10 are diagrams showing the structures of the muffler, the muffler case, and the muffler element, wherein A in each figure shows a conventional structure, and B in each figure shows a structure according to the present embodiment. In addition, in Figure 11 A partial enlarged view of the muffler element according to this embodiment is shown in .

[005

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap