Plastic tube taking, sorting, counting and bundling system

A plastic tube and automatic bundling technology, which is applied in the direction of bundling objects, bundling materials, packaging/bundling items, etc., can solve the problems of low bundling efficiency, weak rigidity, and large space occupation, and achieve high counting and sorting efficiency. The effect of high utilization rate and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the drawings.

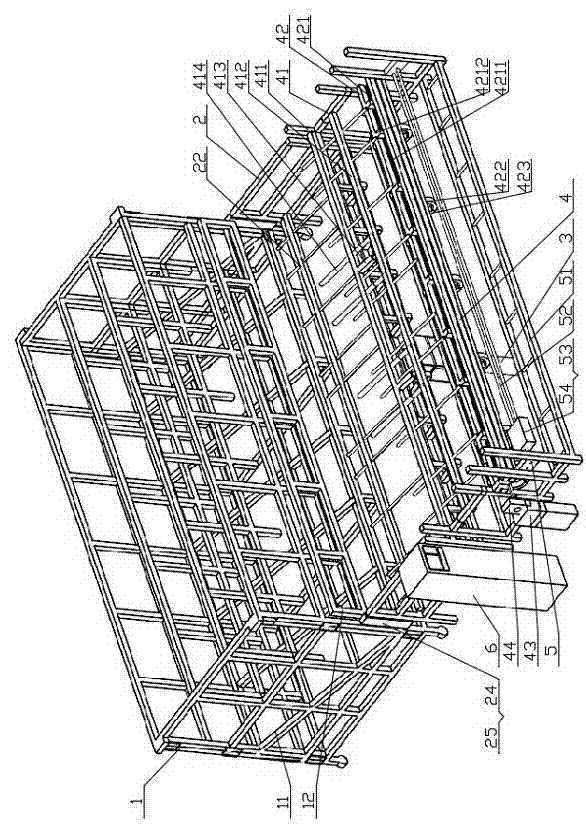

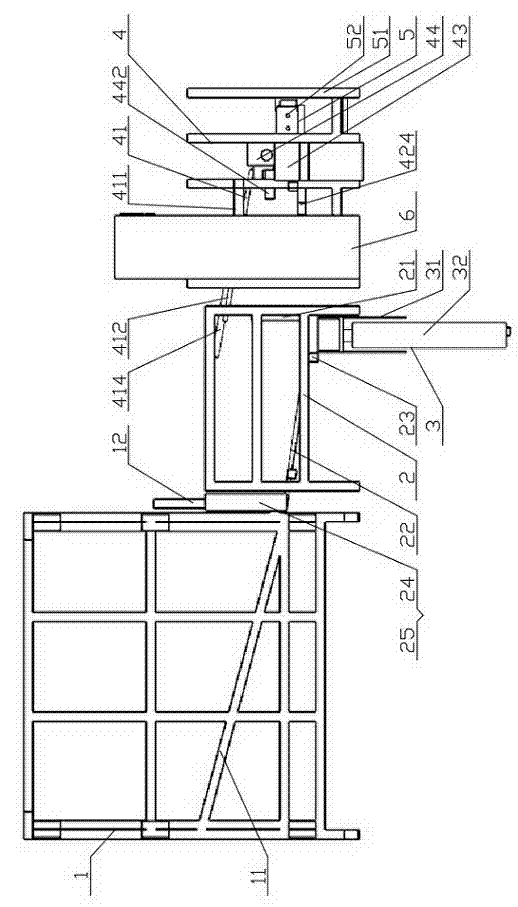

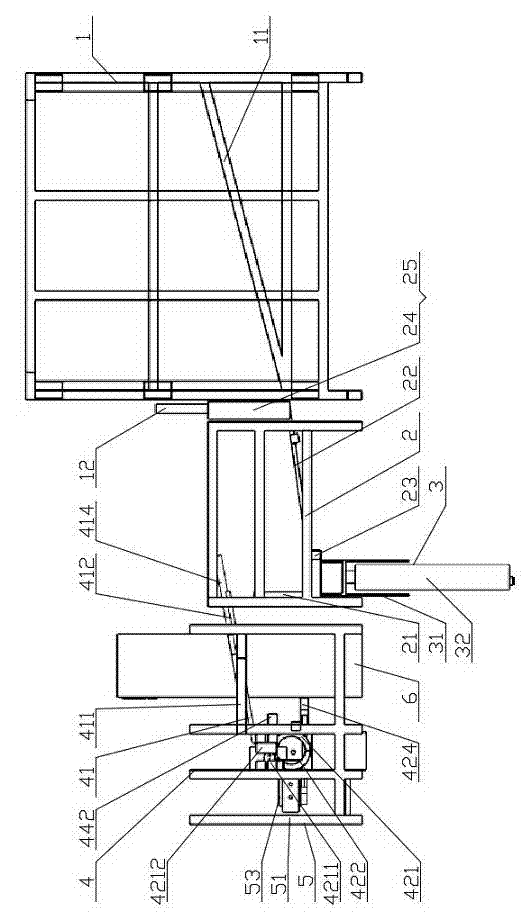

[0044] Such as Figure 1 to Figure 5 As shown, the plastic tube reclaiming, sorting, counting and strapping system includes a feeding silo 1, a transition silo 2, a holding device 3, a sorting and counting device 4, an automatic strapping device 5, and an electric control device 6 (the following description refers to The direction of silo 1 in the entire plastic tube reclaiming, sorting, counting and strapping system is described in the back).

[0045] The feed silo 1 is a box-shaped structure, and its internal width in the left and right directions is matched with the length of the plastic pipe. The rear end of the bottom plate 11 is higher than the front end and is arranged on the horizontal ground. In front of the feed silo 1 A discharge door 12 is provided at the lower part of the panel.

[0046] The transition silo 2 is arranged in front of the feed silo 1 and is a frame structure wit

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap