Vibration-reducing buffer gooseneck of semitrailer

A semi-trailer and gooseneck technology, applied in the field of semi-trailer vibration damping and buffer gooseneck, can solve the problems of vehicle driving performance, driving safety impact, cargo damage, etc., and achieve the effect of reducing relative vibration and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

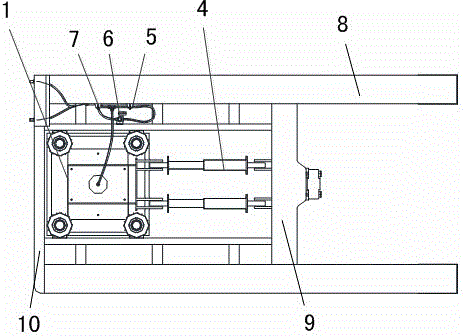

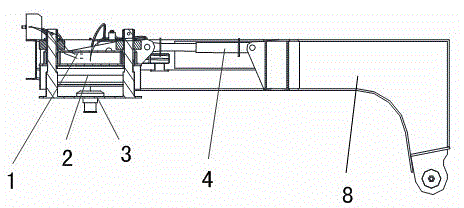

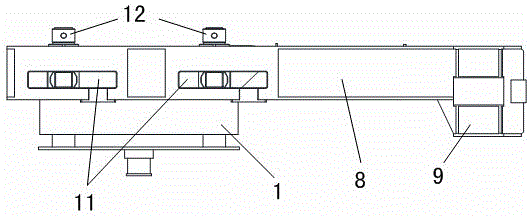

[0023] see figure 1 — image 3 , the present invention relates to a semi-trailer vibration damping and buffering gooseneck, which includes a vibration damping airbag upper bracket 1, a vibration damping airbag 2, a vibration damping airbag lower bracket 3, an oil and gas spring cylinder 4, an intake switch valve 5, a pneumatic damping airbag Pressure valve 6, exhaust switch valve 7, gooseneck longitudinal beam 8, gooseneck rear beam 9 and gooseneck front beam 10. The upper bracket 1 of the vibration-damping airbag is installed on the gooseneck front beam 10, and the guide groove 11 is used to cooperate with the gooseneck longitudinal beam 8, and the lower bracket 3 of the vibration-damping airbag is connected with the saddle of the tractor through a pin shaft , four guide pillars 12 are arranged on the lower bracket 3 of the damping airbag, the upper bracket 1 of the damping airbag is set on the four guide pillars 12, and the damping airbag 2 is fixed on the four guide pillars 1

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap