Backlight FPC wiring structure

A backlight and wire routing technology, which is applied in optics, nonlinear optics, instruments, etc., can solve problems such as backlight not being able to be turned on, wire routing not standardized, golden fingers broken, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

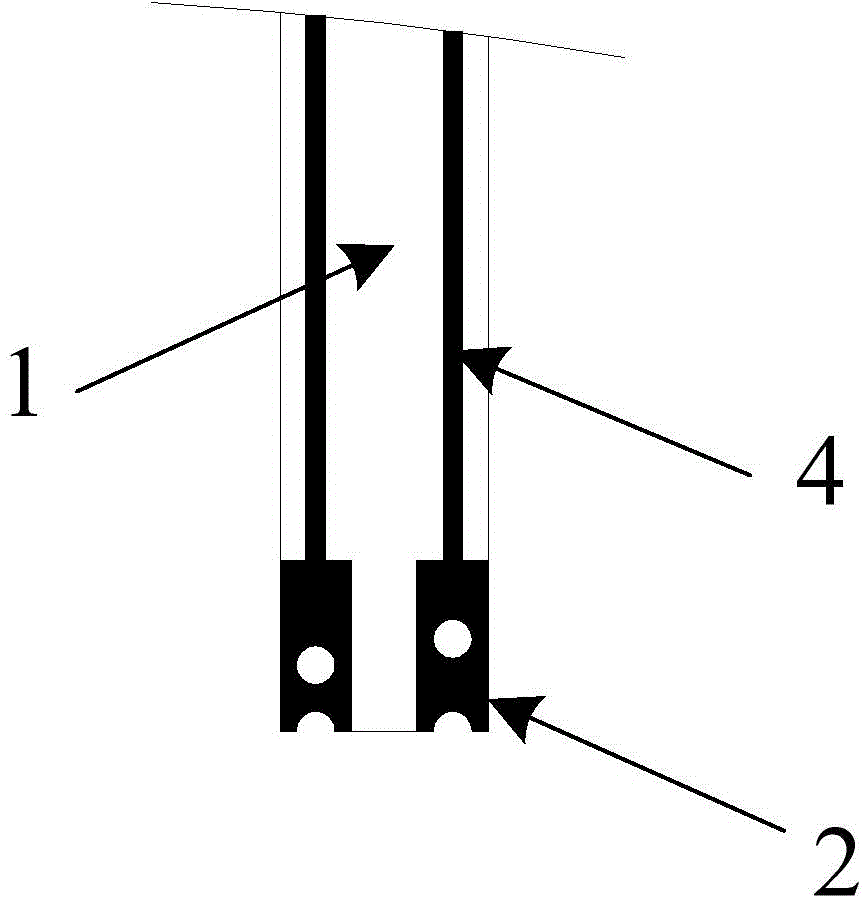

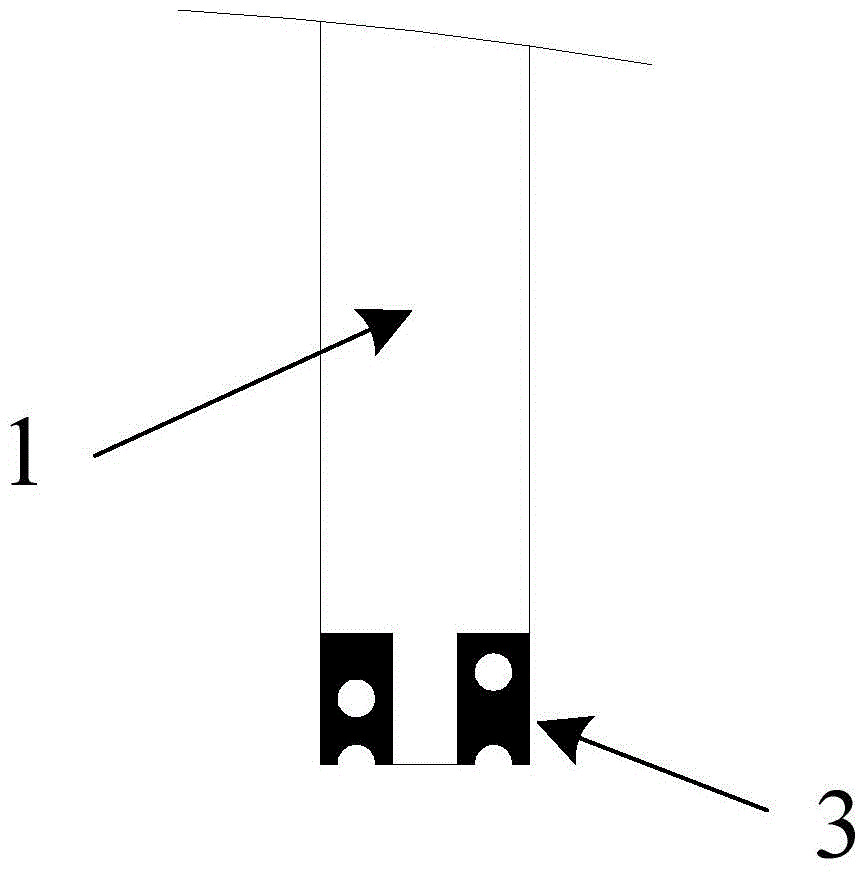

[0012] Such as figure 1 , figure 2 As shown, the present invention includes a backlight FPC1 having two sides. Only long gold fingers 2 are provided on one side of the backlight FPC1, which is defined as the front side of the backlight FPC in this embodiment; only short gold fingers 3 are provided on the other side of the backlight FPC1, which is defined as the back side of the backlight FPC in this embodiment. There is a trace 4 on the front of the backlight FPC, and there is no trace on the back of the backlight FPC. When the backlight FPC1 is bent, the front of the backlight FPC is on the outside of the bend, and the back of the backlight FPC is on the inside of the bend. The short gold finger 3 on the back of the backlight FPC is in contact with the main FPC surface, while the wiring 4, the long gold finger 2 and their connections on th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap