Submodule-assembled three-dimensional positioning mounting method

An installation method and three-dimensional positioning technology, which can be used in measuring devices, instruments, surveying and navigation, etc., and can solve the problems of the stability of the measuring instruments, the large size of the CB20 module, and the complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] refer to Figure 1 to Figure 4 , sub-module assembling three-dimensional positioning installation method, the three-dimensional positioning installation method includes the following steps:

[0049] (1) Selection and embedding of the reference point of the CB20 sub-module assembly site:

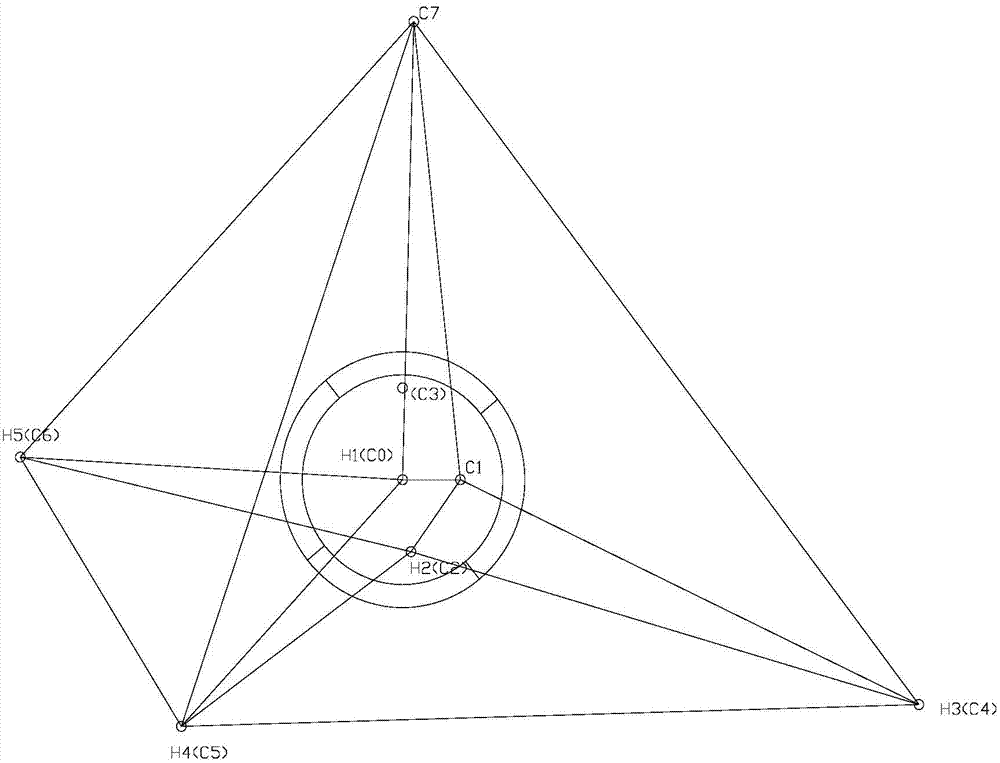

[0050] a1. According to the on-the-spot investigation of the CB20 sub-module assembly site, three plane coordinate control points C0, C1, and C2 are arranged on the inner circle of the CB20 sub-module, and four plane control points C4, C5, C6, and C7 are arranged on the periphery of the CB20 sub-module; It is used to fully control the positioning measurement of the CB20 sub-module on the overall assembly platform;

[0051] a2. According to the convenience of construction survey and combined with the actual situation of the CB20 site, two elevation control points H1 and H2 are arranged on the inner circle of the CB20 sub-module, and three elevation control points H3, H4 and H5 are arrange

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap