Chain-hammer type hair-chiselling machine

A technology of chipping machine and chain hammer, applied in roads, road repair, roads, etc., can solve the problems of slow artificial chipping, delaying construction period, affecting subsequent construction, etc., to reduce traffic control time, reduce road damage, The effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

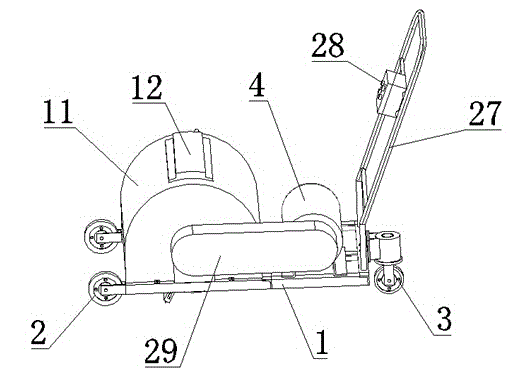

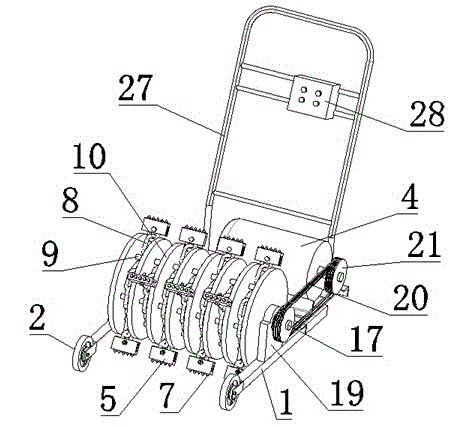

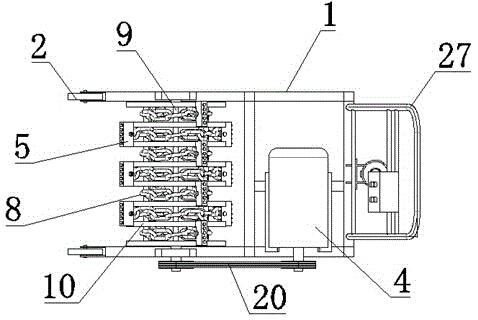

[0026] Such as figure 2 In the shown embodiment, a chain hammer type hair cutting machine includes a bottom beam 1, a motor 4, two fixed wheels 2 fixed on the front end of the bottom beam 1 and a direction wheel 3 installed on the rear end, and the bottom beam 1 is equipped with chiseling device, the chiseling device includes a hammer 5 and a transmission device, a groove 6 is formed on the hammer 5, an alloy head 7 is arranged in the groove 6, and the alloy head 7 and the hammer 5 are connected by brazing;

[0027] The transmission device includes a chain 8, a connecting shaft 9 and a partition 10. The partition 10 is a circular steel plate, and two adjacent partitions 10 are connected by a connecting shaft 9. There are four connecting shafts 9, and they are evenly distributed on the partition 10. The side of the chain 8 passes through the connecting shaft 9, and is coiled between two adjacent partitions 10. The hammer 5 is connected to the chain 8 through bolts, and two hammer

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap