Steel pulling strip fixing structure for transformer

A fixed structure and transformer steel technology, applied in the field of transformers, can solve problems affecting the safe operation of transformers, short-circuiting steel straps to iron cores, accelerating the aging of the strap insulation, etc., to avoid electrical breakdown of insulation, reduce loss of structural parts, and improve Effect of impact mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

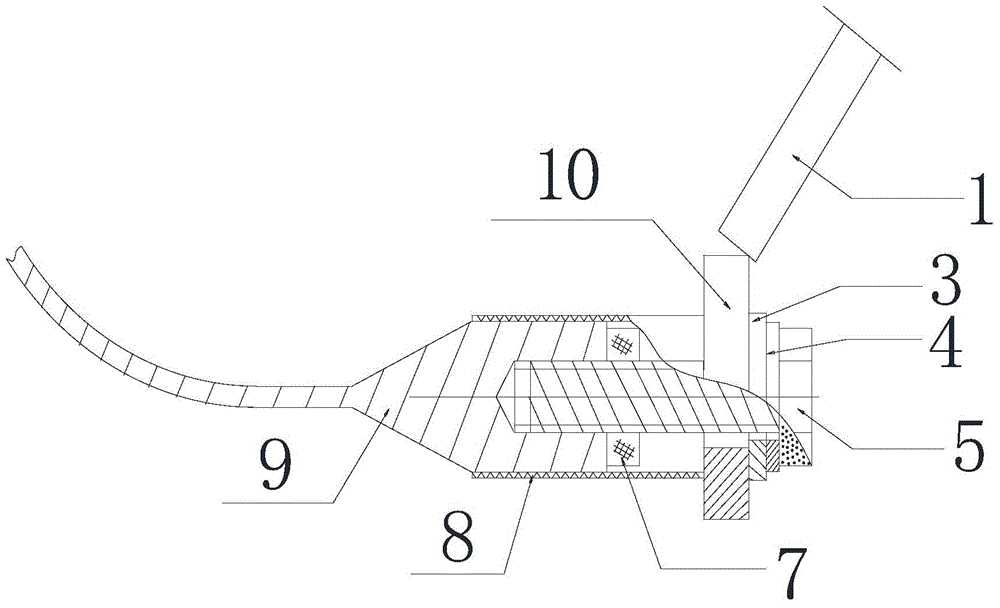

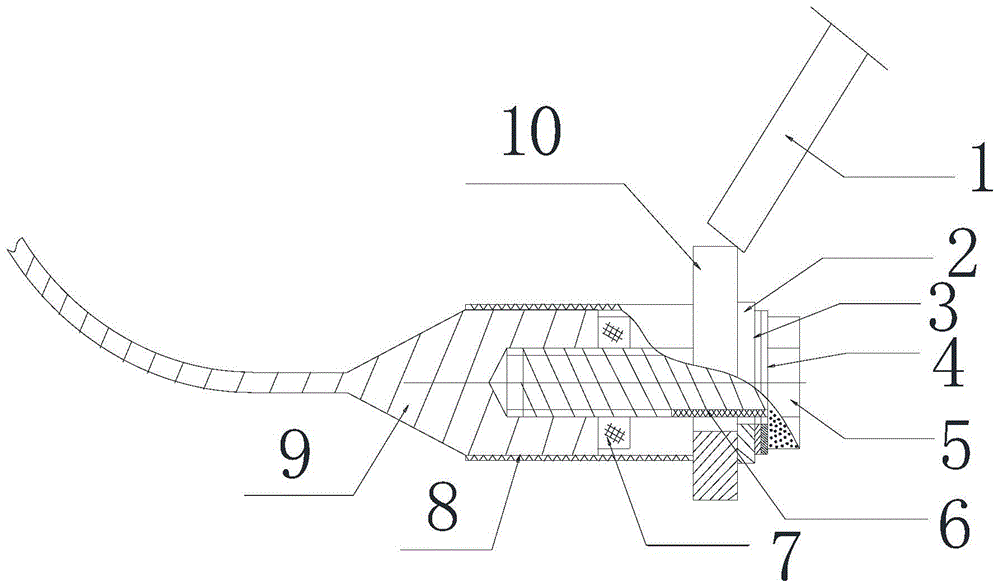

[0016] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

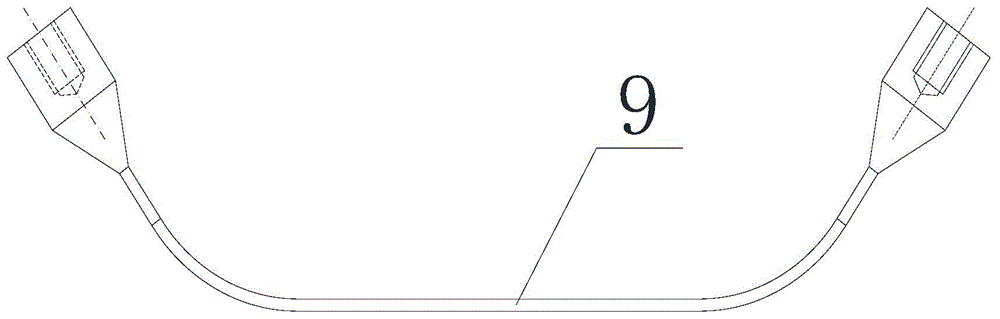

[0017] Such as Figure 1-3 As shown, a transformer steel strap fixing structure includes a steel strap body 9 with bolt seats welded at both ends, fastening bolts 5 and fastening nuts 7, butterfly spring 4, insulating paper tube 8, insulating washer 2 and steel The washer 3; the two ends of the steel drawstring body 9 are respectively fixed on the drawstring fixing plate 10 through the cooperation between the fastening bolt 5 and the fastening nut 7 and connected with the high / low pressure upper / lower clip 1. ;

[0018] Such as image 3 As shown, one of the two ends connected between the steel drawstring body 9 and the h

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap