Shrimp strip dryer

A drying machine and shrimp stick technology, which is applied in dryers, drying, non-progressive dryers, etc., can solve the problems of affecting eating health, reducing the oil content of shrimp sticks, increasing the oil content of shrimp sticks, etc. Healthy eating, good drying effect, reducing oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

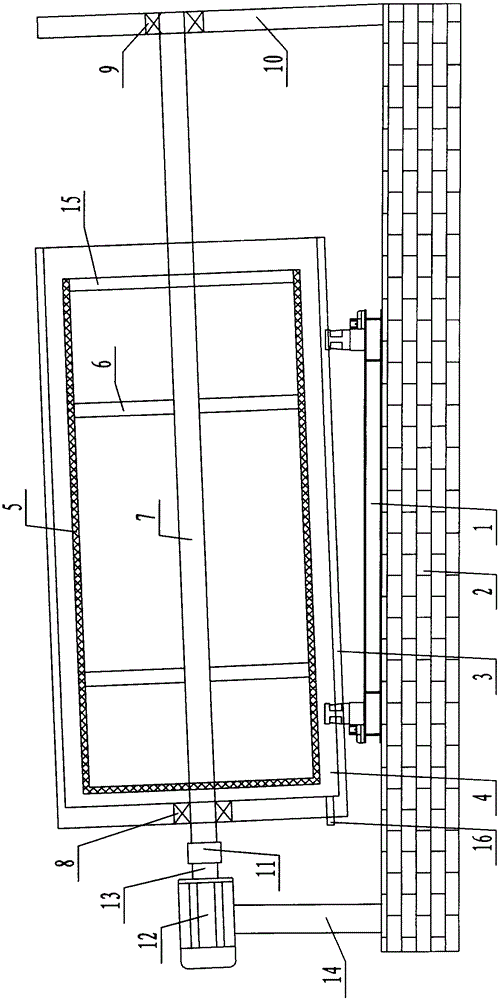

[0009] Such as figure 1 As shown, the shrimp cracker dryer includes: a frame 1, the frame 1 is supported on the ground 2, an outer cylinder 3 is arranged obliquely on the frame 1, and an outer cylinder 3 is arranged inside the outer cylinder 3 There is an oil collection chamber 4, and a grid-shaped inner cylinder 5 is arranged obliquely in the oil collection chamber 4. The grid-shaped inner cylinder 5 is connected with a rotating shaft 7 through a connecting rod 6, and one end of the rotating shaft 7 Pass through the grid-shaped inner cylinder 5 and rotate it on the outer cylinder 3 through the first bearing seat 8, and the other end of the rotating shaft 7 protrudes from the outer cylinder 3 and rotate it on the support seat 10 through the second bearing seat 9. The support base 10 is supported on the ground 2, and one

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap