Interlocked stop nut assembly

A technology of anti-loosening nuts and components, which is applied in the direction of nuts, threaded fasteners, locking fasteners, etc., can solve the problem of limited role of anti-loosening teeth, and achieve the purpose of preventing vibration, unscrewing and loosening, and large effective length Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

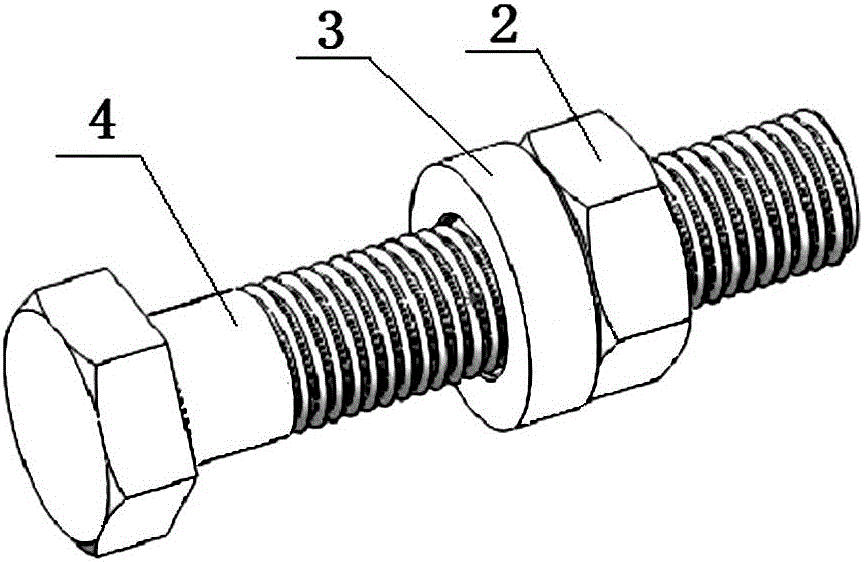

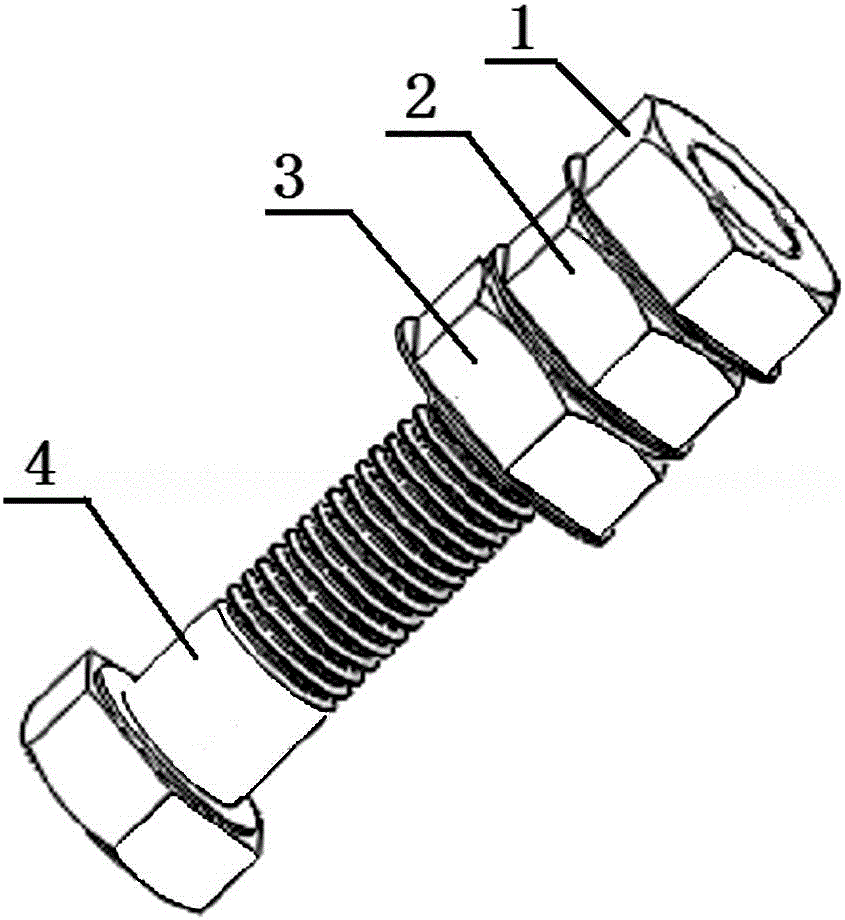

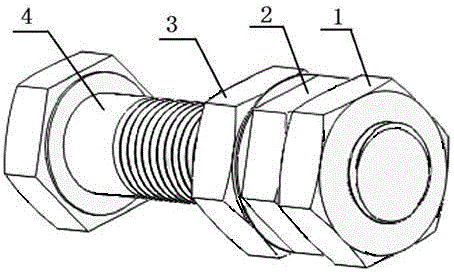

[0039] Such as figure 1 , 2 The interlocking locknut assembly composed of two components shown is composed of an eccentric nut 2 and a washer 3 , and the two components of the eccentric nut 2 and the washer 3 are matched and fitted on the bolt 4 for fastening the parts. Such as image 3 , 4 As shown, the lower end of the eccentric nut is provided with a lower conical boss 2-2, the center of the lower conical boss does not coincide with the thread center of the eccentric nut, and its eccentricity a is the fit gap plus the eccentric nut and the bolt. The sum of the fit clearance between the upper gasket and the bolt. In order to facilitate the automatic locking device to tighten the eccentric nut, such as Figure 5 , 9 As shown, a flange 2-3 is provided on the lower side edge of the eccentric nut, and the flange can play a role in positioning the automatic locking device, so as to facilitate the tightening operation of the eccentric nut. Such as Figure 6 , 7As shown, ther

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap