Optical fiber insulator insertion loss detector

A technology for insertion loss and insulators, which is applied in the field of optical fiber insulator insertion loss detectors, can solve the problems of not being able to detect the insertion loss or attenuation performance of optical fiber insulators, and achieve the effects of easy operation, accurate measurement, and convenient calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

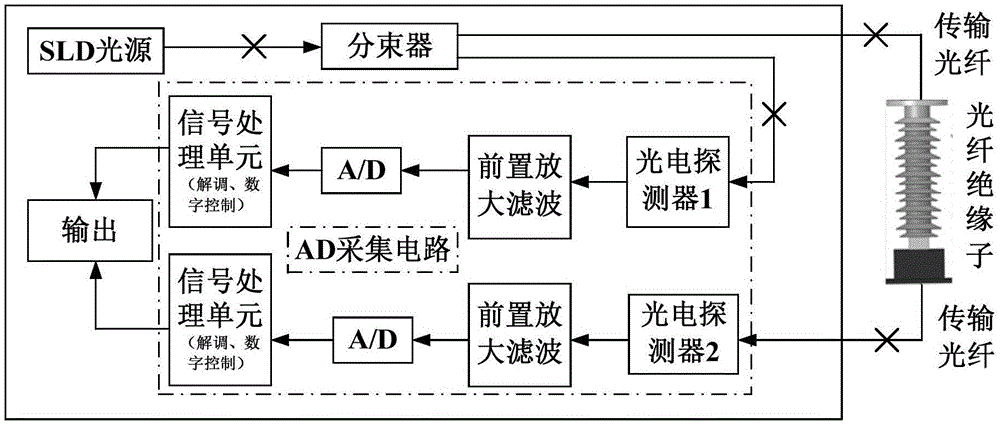

[0017] Such as figure 1 As shown, the optical fiber insulator insertion loss tester of the present invention includes an SLD light source and a light source driving module thereof, a beam splitter capable of dividing an input optical signal into two optical signals whose intensity ratio is close to 1:1, and a first Outgoing optical fiber, second outgoing optical fiber, incident optical fiber, AD acquisition circuit and output display device, wherein the AD acquisition circuit is provided with first and second optical power measurement values that can measure the optical power of the input optical signal and output the optical power measurement value as a digital signal Two optical power measurement modules; the light source driving module is electrically connected to the driving end of the SLD light source, the output end of the SLD light source is connected to the input end of the beam splitter through an optical fiber, and the two output ends of the beam splitter are respectiv

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap