A high-speed dynamic pressure gyro motor ground contact speed test system

A dynamic pressure gyro motor and testing system technology, which is applied in the direction of motor generator testing, mechanical bearing testing, mechanical component testing, etc., can solve problems such as the inability to quantify and evaluate the state of air bearings, prevent aliasing effects, and improve signal quality. The effect of the noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0052] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

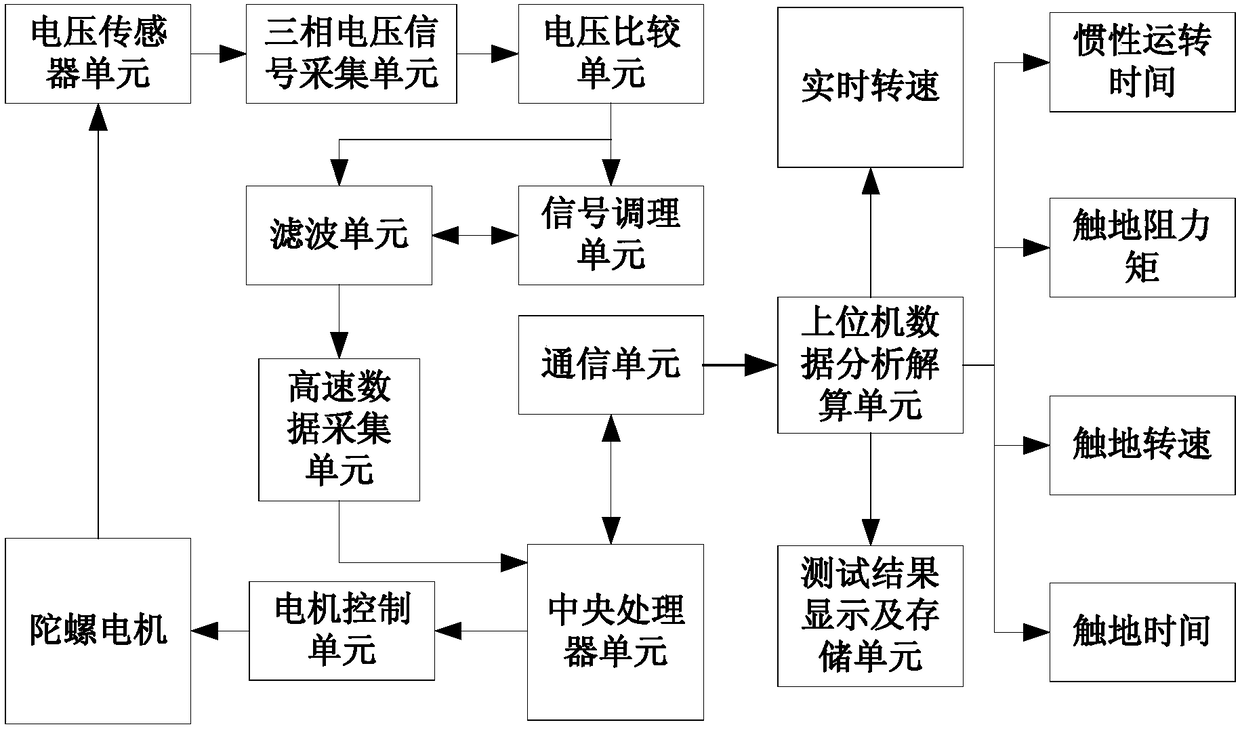

[0053] Such as figure 1 Shown is the principle block diagram of the ground speed test system for the high-speed dynamic pressure gyro motor. As can be seen from the figure, it includes the motor control unit, voltage sensor unit, three-phase voltage acquisition unit, voltage comparison unit, signal conditioning unit, filter unit, and high-speed data acquisition unit , Central processing unit, communication unit, upper computer data analysis and calculation unit, test result display and storage unit;

[0054] Motor control unit: receives the control signal from the central processing unit, and controls the start and stop of the external gyro motor;

[0055] Voltage sensor unit: Test the three-phase reverse electromotive force of the external gyro motor after power off, generate a three-phase voltage signal, and transmit it to the three-phase voltage acquisit

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap