Lifting moving type hydraulic trolley for dismounting and mounting of bolts through bottom ring stretching

A tension bolt and mobile technology, which is applied in the field of bottom ring tension bolt disassembly and assembly lifting and moving hydraulic trolley, can solve the problems of bolt and tensioner thread damage, labor consumption, and difficulty in bolt disassembly and assembly. The effect of dismantling efficiency, reducing labor intensity and high disassembly and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

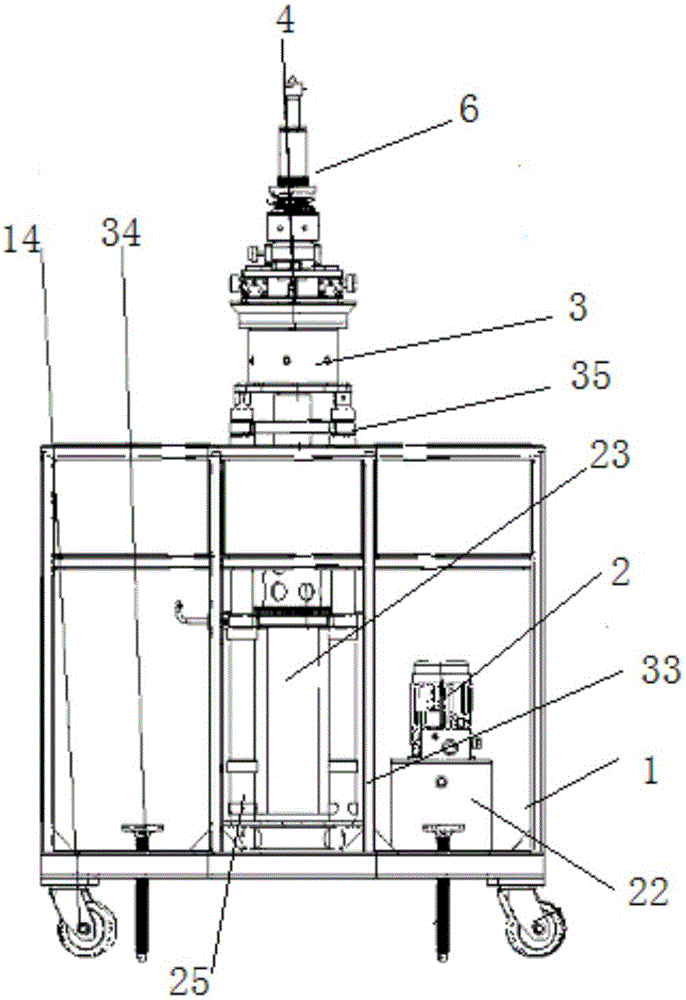

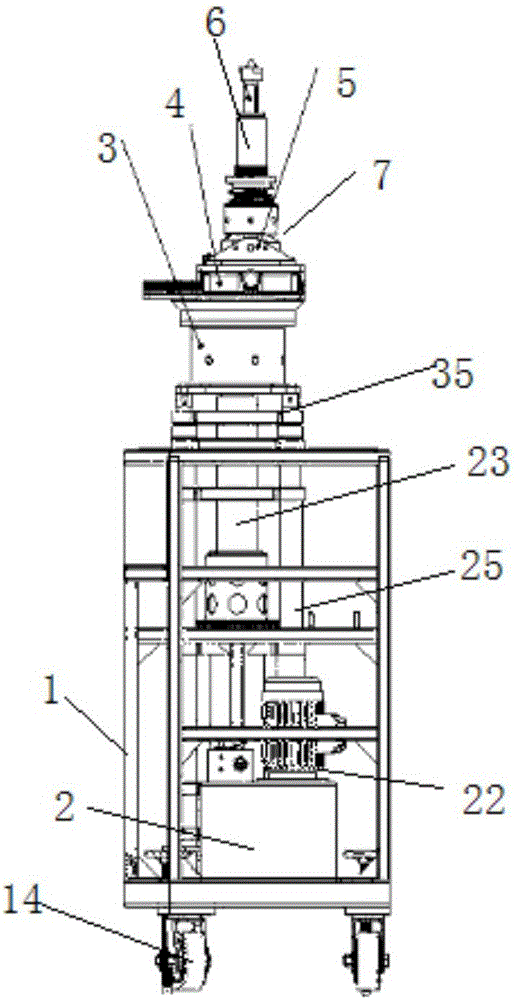

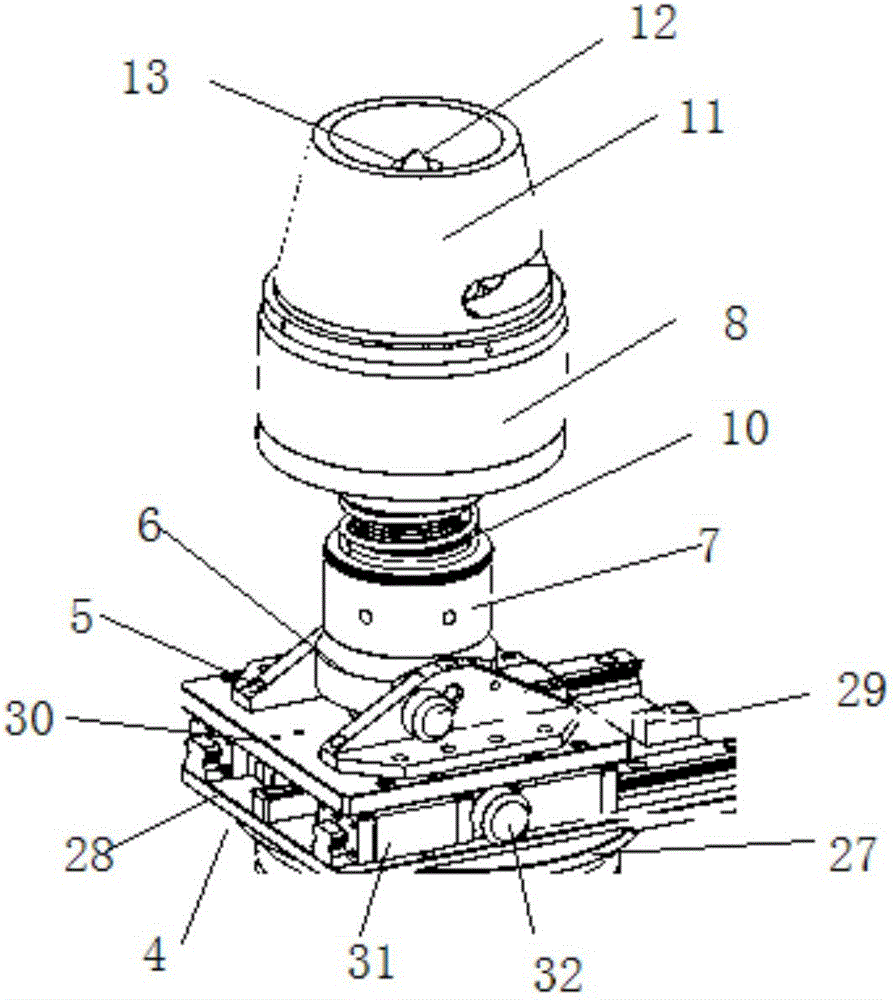

[0023] Embodiment: a bottom ring stretching bolt disassembly lifting mobile hydraulic trolley, constituted as follows figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the mobile frame 1 is included, the hydraulic device 2 is arranged in the mobile frame 1, the rotating assembly 3 connected with the mobile frame 1 is arranged above the hydraulic device 2, the displacement assembly 4 is arranged above the rotating assembly 3, and the displacement assembly 4 is provided above The swing assembly, the swing assembly includes a swing shaft support 5 connected with the displacement assembly 4, a swing shaft bolt 6 is connected between the swing shaft support 5, a swing nut 7 is provided at the bottom of the swing shaft bolt 6, and a pull-up nut 7 is provided at the top of the swing nut 7. A compression spring 10 is arranged between the stretcher 8, the stretcher 8 and the screw nut 7, a bridge frame 11 is arranged above the stretcher 8, and a centering cone top 12

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap