Equipment for automatically detecting steel-plastic adapter

A steel-plastic conversion joint, automatic detection technology, applied in the direction of detecting the appearance of fluid at the leak point, measuring device, fluid tightness test, etc. Low problems, to achieve the effect of convenient observation, low misjudgment rate, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

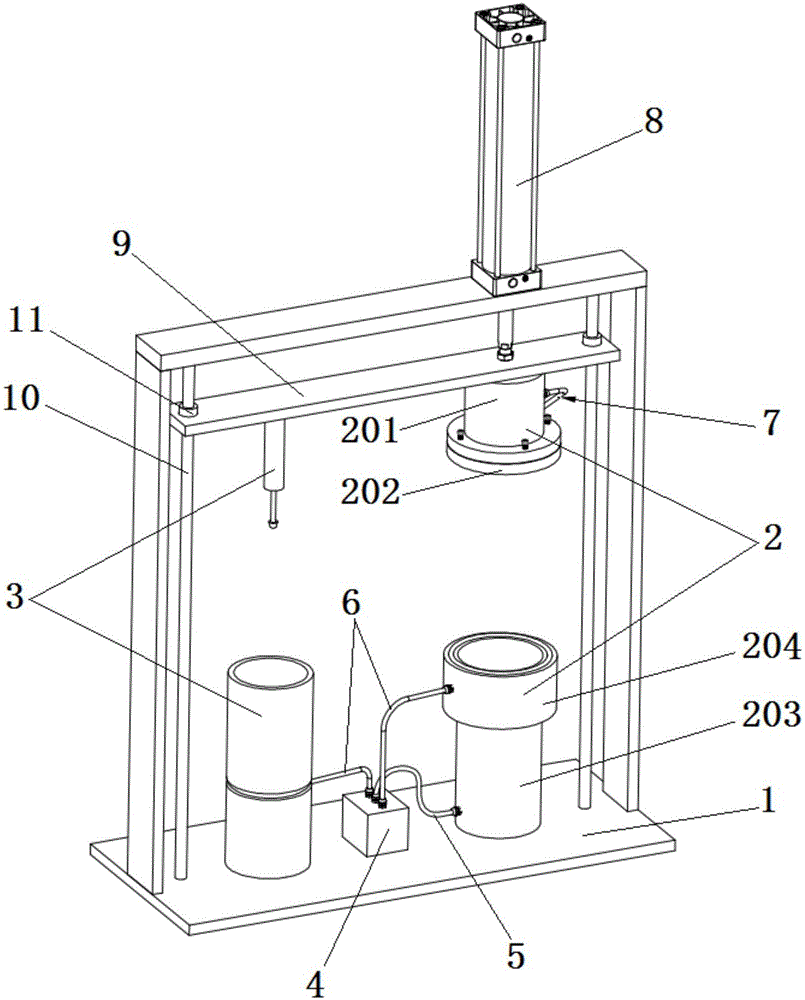

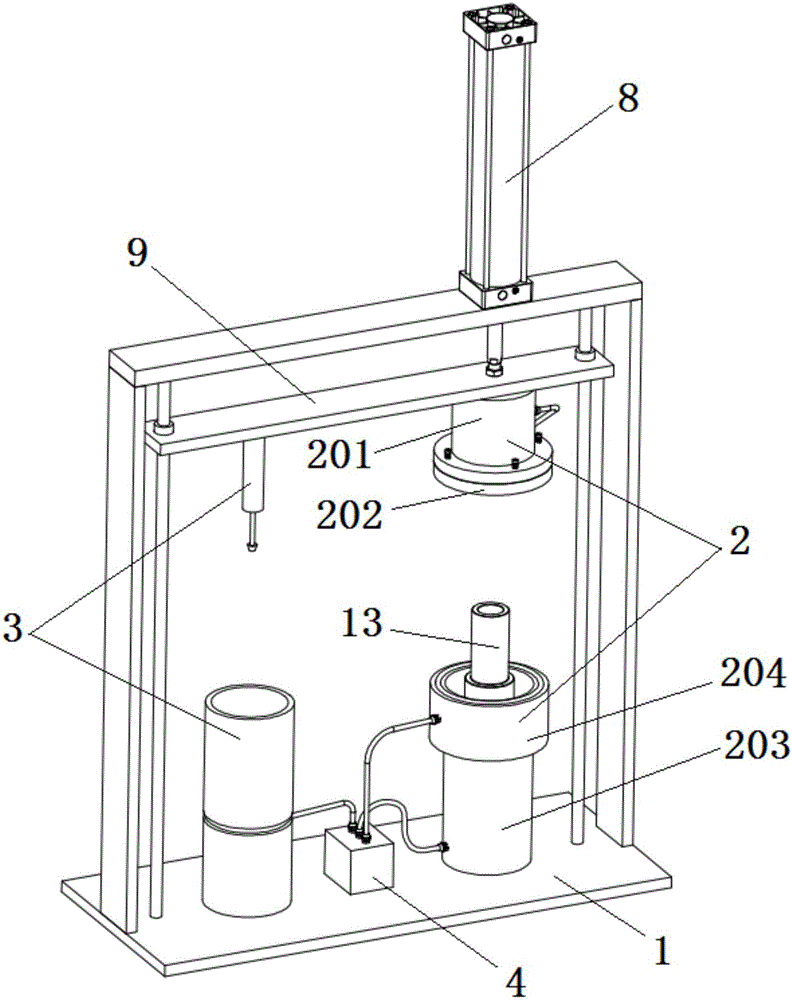

[0033] A kind of equipment of automatic detection steel-plastic conversion joint, see figure 1 , figure 2 , including a base 1, a sealing mechanism 2 and a leak detection mechanism 3 arranged on the base 1, and a gas path communication mechanism 4 arranged between the sealing mechanism 2 and the leak detection mechanism 3.

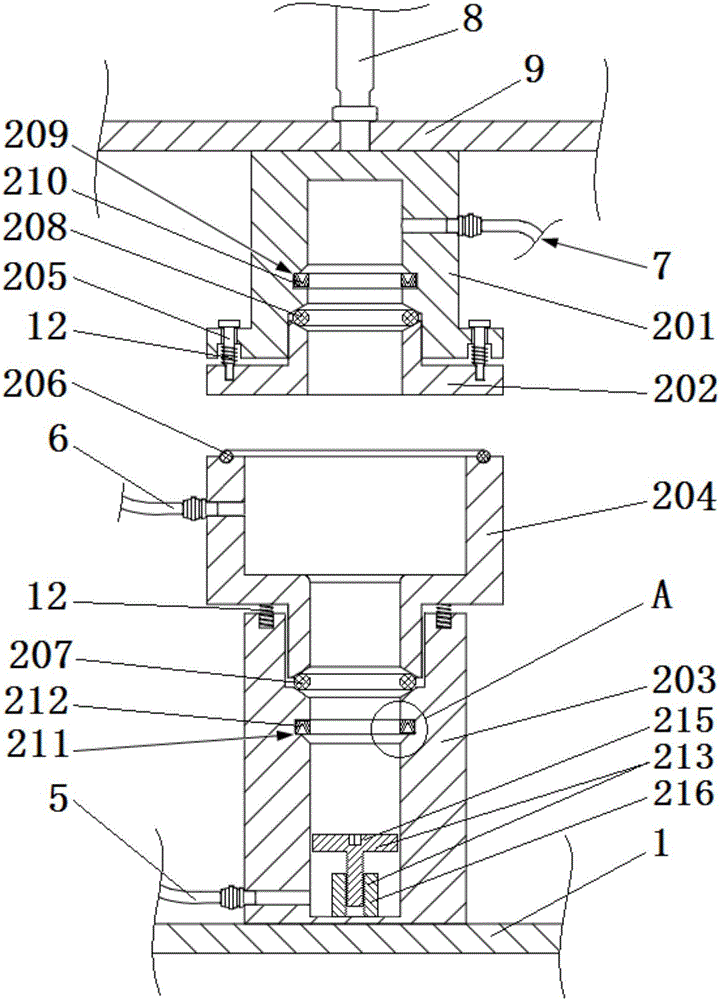

[0034] The sealing mechanism 2 includes an upper base 201, an upper movable seat 202, a lower base 203, and a lower movable seat 204, such as Figure 3 to Figure 5As shown; the lower base 203 is in the shape of a barrel with an open upper end and a bottom at the lower end. The longitudinal section of the lower movable seat 204 is an inverted "convex" shape, and the upper and lower ends of the interior are connected. The lower side of the lower movable seat 204 can slide in the upper opening of the lower base 203. A number

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap