Foldable spliced vehicle-mounted assembled storage box

A sorting and assembling technology, applied in packaging, transportation and packaging, rigid containers, etc., can solve the problems of inconvenient folding of the constant structure, reduce the quality of use by passengers, affect the quality of placed items, etc. Small space, small footprint, easy storage and access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

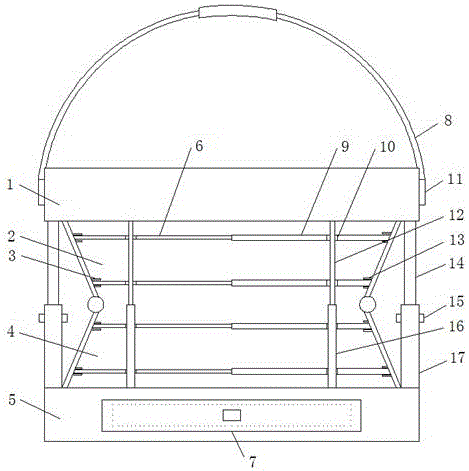

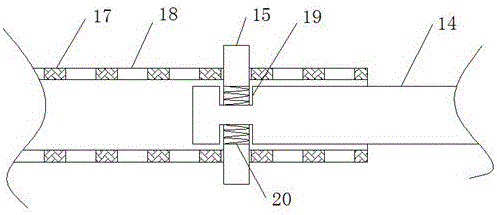

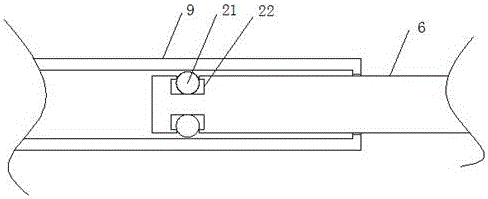

[0019] refer to Figure 1-3 , a foldable and assembled vehicle-mounted finishing box, comprising a top plate 1 and a base plate 5, the top plate 1 is located directly above the base plate 5, an upper box body 2 is provided on the side of the top plate 1 close to the base plate 5, and both sides of the upper box body 2 are A connecting rod 14 is provided, a lower box body 4 is provided on the side of the base plate 5 close to the top plate 1, and vertical supporting rods 17 are arranged on both sides of the lower box body 4, wherein the upper box body 2 and the lower box body 4 are hinged , the upper box 2 communicates with the lower box 4, the support rod 17 is a cavity structure, both sides of the support rod 17 are provided with through holes 18, one end of the connecting rod 14 extends into the supporting rod 17, and the connecting rod 14 Slidingly connected with the inner wall of the support rod 17, the side of the connecting rod 14 close to the support rod 17 is provided wit

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap