Self-centering buckling restrained brace end connecting device

A technology of buckling restraint and supporting end, applied in the direction of building components, earthquake resistance, building type, etc., can solve the problems of high initial stiffness and pre-tensioning rod fracture, so as to reduce initial stiffness, reduce construction costs, reduce non-structural components and The effect of the degree of equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

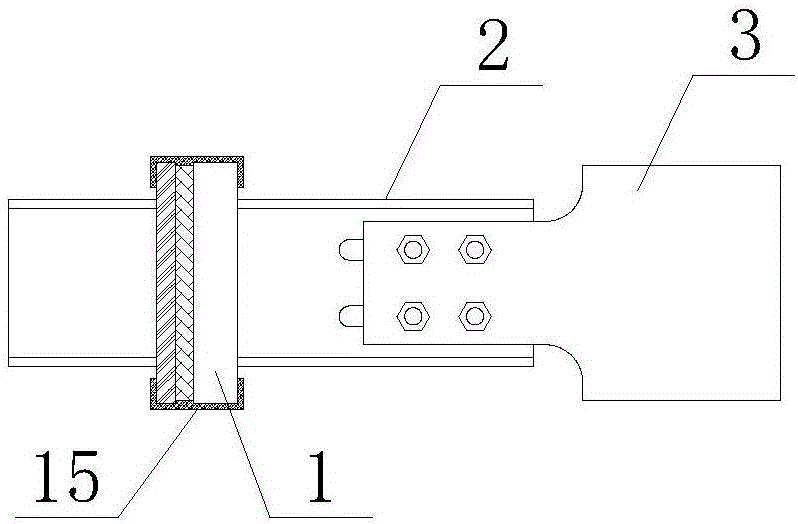

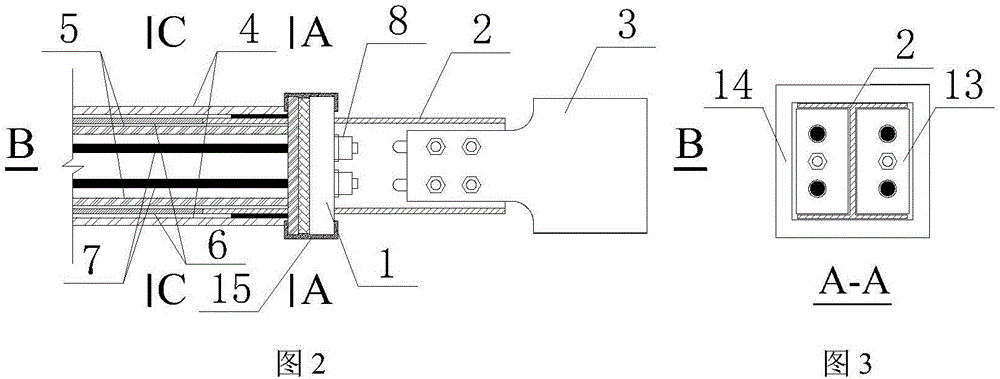

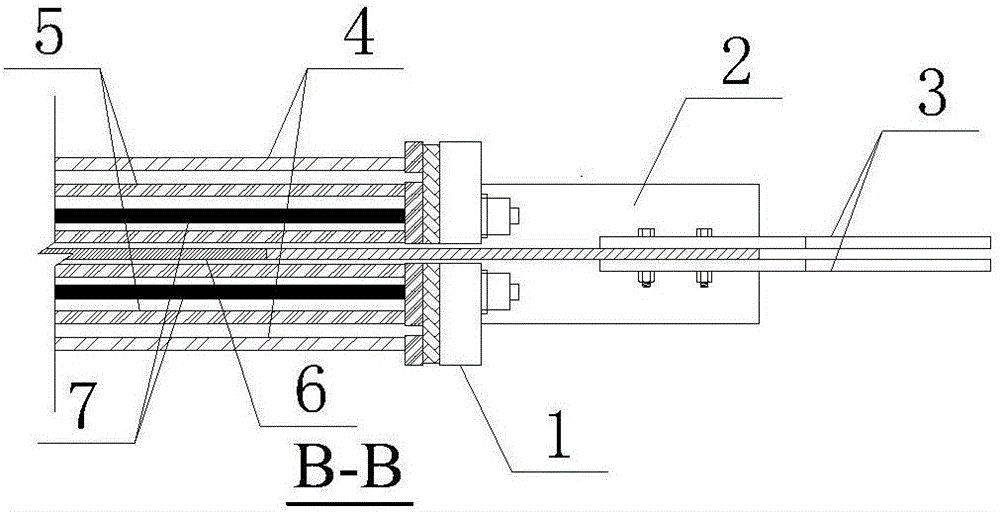

[0033] Such as Figure 1~Figure 5 and Figure 10~ Figure 14 As shown, the self-centering buckling restraint support end connecting device of the present invention includes a sandwich rubber end plate 1, an I-shaped connecting plate 2 passing through the interlayer rubber end plate 1, and is arranged on the unconstrained end web of the I-shaped connecting plate 2 Friction plates on both sides 3. The interlayer rubber end plate 1 includes a rubber pad 12, an end plate 11 arranged on one side of the rubber pad 12 facing the friction plate 3, an outer backing plate 14 arranged on the other side of the rubber pad 12, and two inner backing plates 13, the outer backing plate 14 is located on the outside of the two inner backing plates 13, and there is a gap between the outer backing plate 14 and the inner backing plate 13, the end plate 11, the rubb

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap