Test system for cycling stability of chemical heat accumulation

A technique for cyclic stability, testing systems, applied in the direction of weighing by removing a certain component, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

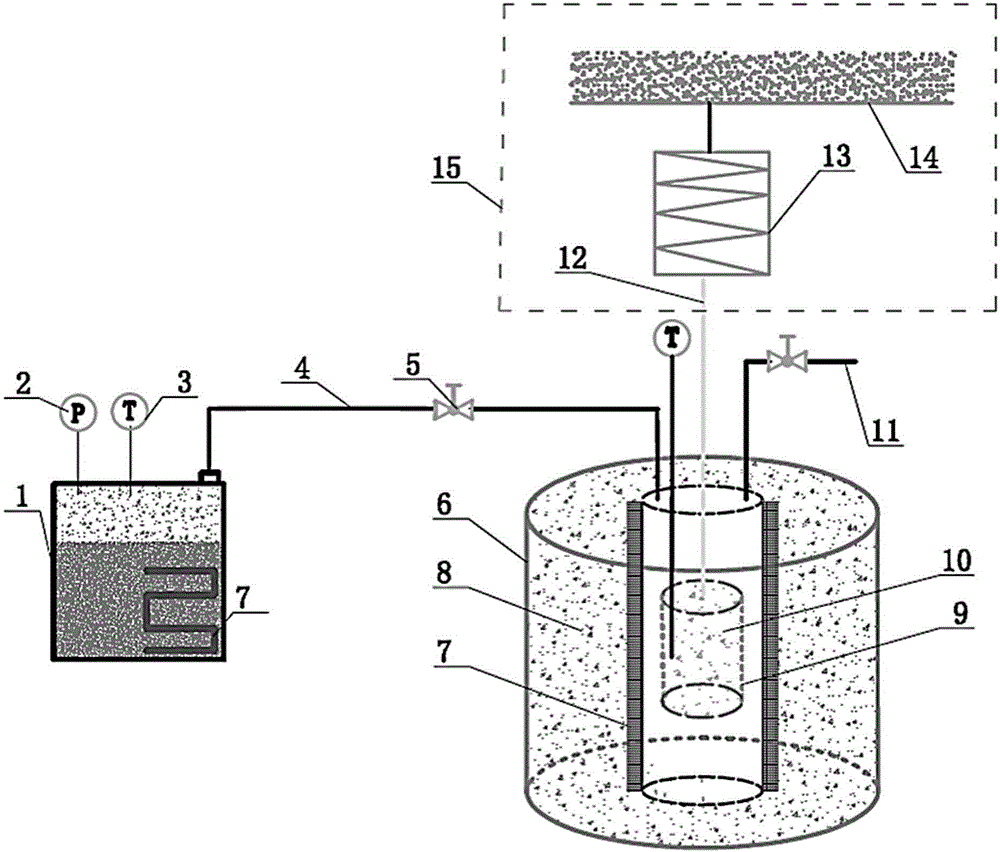

[0027] Such as figure 1 As shown, this embodiment includes: thermometer 3, pressure gauge 2, sample container 9, heating device 7, weighing monitoring device 15, hoisting wire 12, pipeline 4, valve 5, steam generator 1 and heating furnace 6, wherein The steam generator 1 and the heating furnace 6 are connected through the pipeline 4 provided with the valve 5, and the thermometer 3 is arranged in the steam generator 1 and the sample container 9 respectively; the heating device 7 is respectively arranged in the steam generator 1 and the heating furnace 6, the pressure gauge 2 is set on the steam generator 1; the sample container 9 is hoisted and installed inside the structure of the heating device 7 in the heating furnace 6, and the sample container 9 is connected to the weighing monitoring device 15 through the hoisting wire 12.

[0028] The steam generator 1 provides continuous and stable water vapor for the stability test of the chemical heat storage cycle through the pipeline 4

Embodiment 2

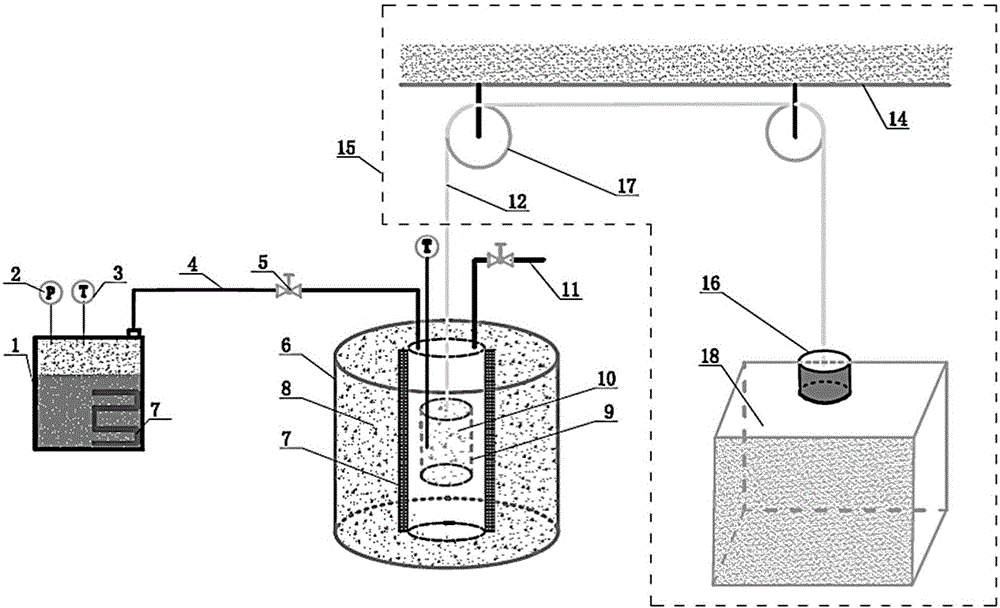

[0044] Such as figure 2 As shown, the weighing structure 13 of this embodiment is a high-precision electronic scale weighing structure 13 .

[0045] The high-precision electronic scale weighing structure 13 includes: a weight 16, a pulley block 17 and a high-precision electronic scale 18, wherein: the weight 16 is placed on the high-precision electronic scale 18, and the weight 16 is located under the pulley block 17.

[0046] The lifting wire 12 is connected with the weight 16 through a pulley block 17 .

[0047] The weighing monitoring device 15 obtains the weight change of the sample 10 according to the weight change of the weight 16 monitored by the high-precision electronic scale 18, and then obtains the reaction progress of the chemical heat storage, and judges the progress of each cycle in the cycle stability test. Degree.

[0048] During the test, open the valve 5 between the steam generator 1 and the heating furnace 6, add the sample 10 into the sample container 9, th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap