Wave energy recycling device

An energy recovery device and energy recovery technology, applied in ocean energy power generation, machines/engines, mechanical equipment, etc., can solve problems such as ignoring wave vibration energy reuse, and achieve the effects of simple structure, long service life, and simple and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with specific examples

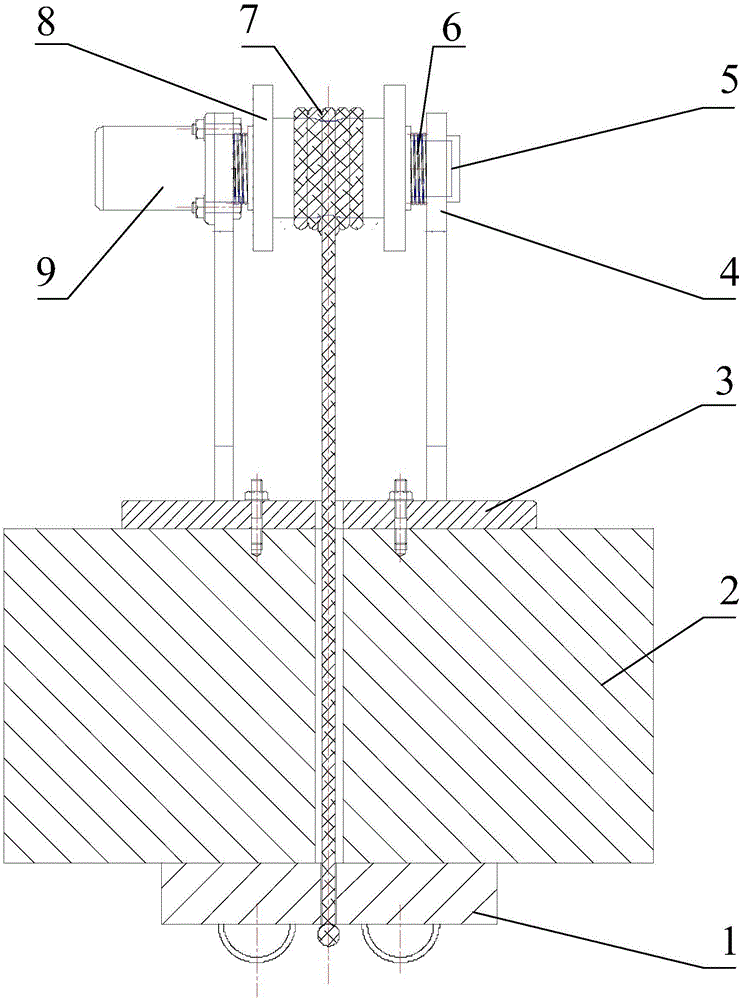

[0015] figure 1 The wave energy recovery device mainly includes an axis hollow buoy 2 , an energy recovery device and a special cable device 1 . The energy recovery device mainly includes a bottom plate 3, a torsion spring 6, a supporting rib 4, a tapered roller bearing 5, a generator 9 and the like.

[0016] The wave energy recovery device in the present invention is bolted to the buoy 2 through four positioning holes on the flange plate 3 of the bottom plate; the integrated drum 8 includes a cable winding shaft in the middle and circular baffles at both ends; the drum 8 is supported by a tapered roller bearing 5, and the outer ring of the bearing is welded to the supporting rib 4; the roller 8 is connected to the supporting rib 7 through a torsion spring 6; the rotating shaft of the generator 9 is connected to the roller 8 through a spline; The generator casing is fixed to t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap