Adapter of gas stove

A technology for converting joints and gas cookers, applied in the direction of pipes/pipe joints/pipes, threaded connections, sealing surface connections, etc., can solve the problems of easy damage, poor safety, easy combustion, etc. Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

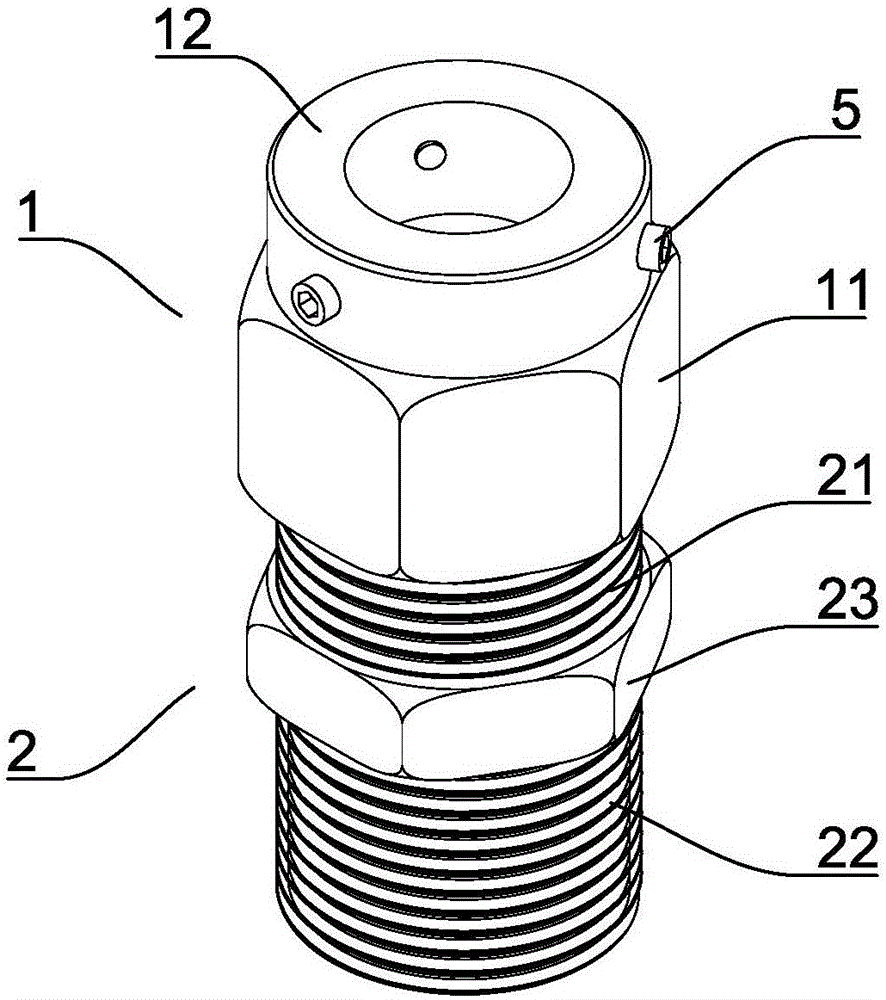

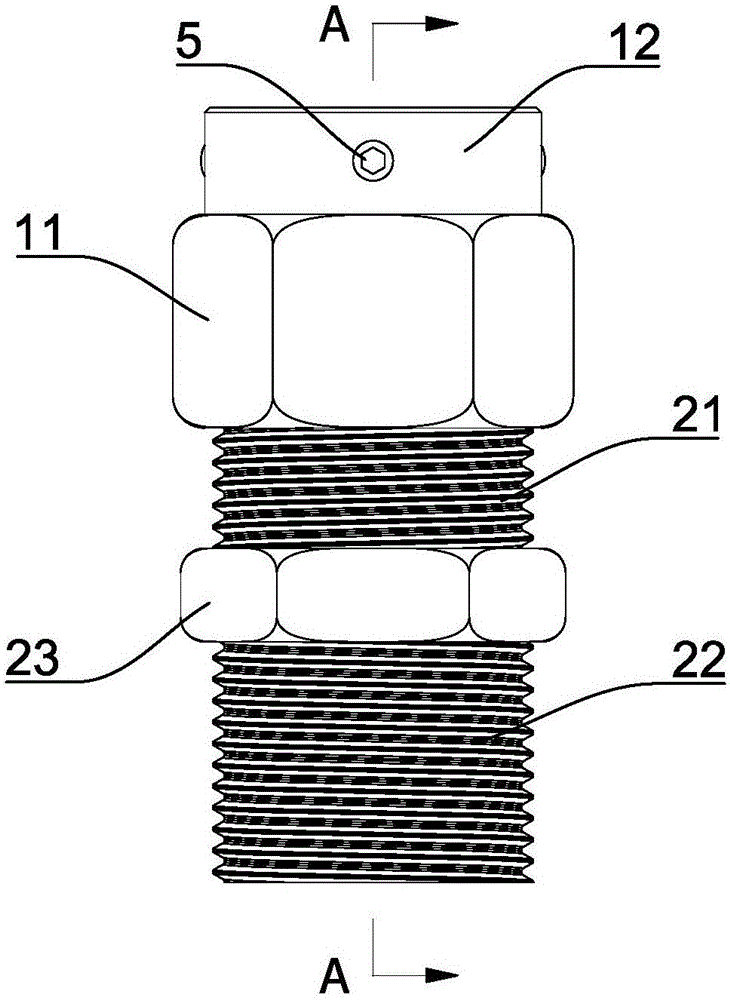

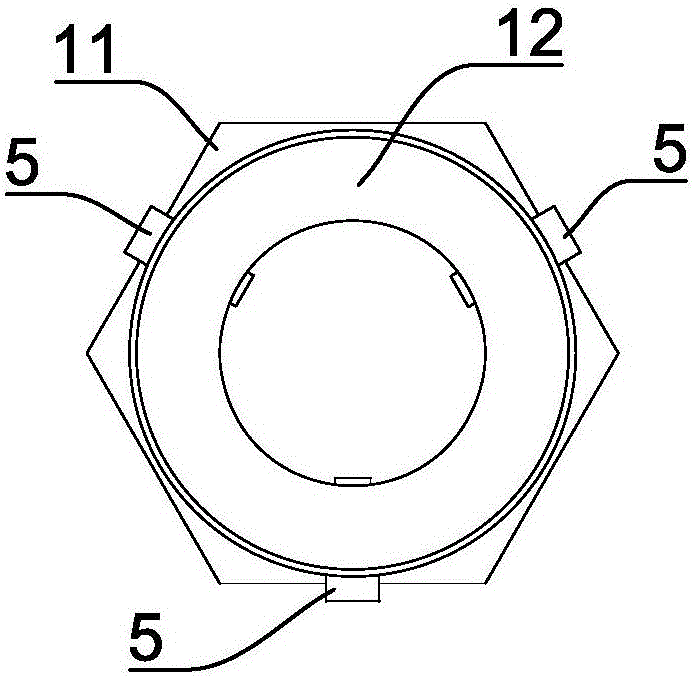

[0017] Such as Figure 1 to Figure 6 Shown is a specific embodiment of a gas cooker adapter according to the present invention, including a first connecting piece 1 , a second connecting piece 2 , a pressure bearing ring 3 and a sealing sleeve 4 . The first connecting piece 1 specifically includes a lock nut 11 and a short sleeve 12 connected as one, the lock nut 11 and the short sleeve 12 are coaxial and the inner diameter of the lock nut 11 is larger than the inner diameter of the short sleeve 12 . Let the second connecting piece 2 adopt an externally threaded pipe joint structure, which specifically includes an upper threaded pipe 21, a lower threaded pipe 22, and a hexagonal head 23 arranged between the upper threaded pipe 21 and the lower threaded pipe 22. A limit ring platform 24 is provided on the inner peripheral wall. When installing and using, let the first connecting piece 1, the pressure bearing ring 3 and the sealing sleeve 4 be sleeved on the socket interface of th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap