Acoustic emission based bolt fracture signal detection method

A technology of signal detection and acoustic emission, which is applied in the direction of material analysis, instruments, and analysis materials using acoustic emission technology, which can solve problems such as false alarms, falling blades, broken towers, etc., and achieve rich detection functions and detection The results are accurate and the effect of reducing missing alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is attached Figures 1 to 6 , to further illustrate a specific implementation of the acoustic emission-based bolt fracture signal detection method of the present invention. A method for detecting a bolt fracture signal based on acoustic emission in the present invention is not limited to the description of the following embodiments.

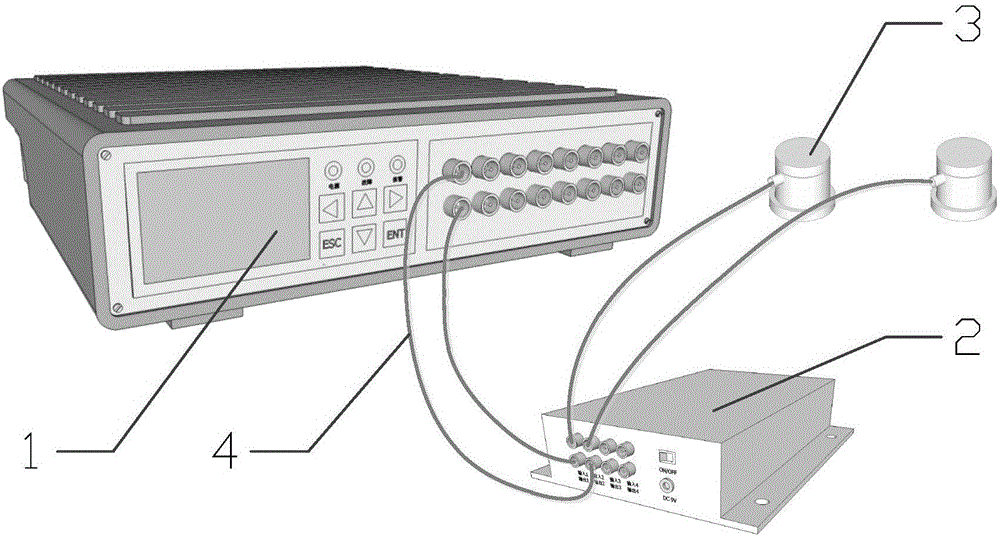

[0022] Such as figure 1 Shown is a schematic diagram of the overall structure of the detection device used in the acoustic emission-based bolt fracture signal detection method of the present invention, including a host 1, a pre-signal amplifier 2 and an acoustic emission sensor 3, the host 1 and the pre-signal amplifier 2, the pre-signal amplifier 2 and the acoustic emission sensor 3 are connected by a cable 4.

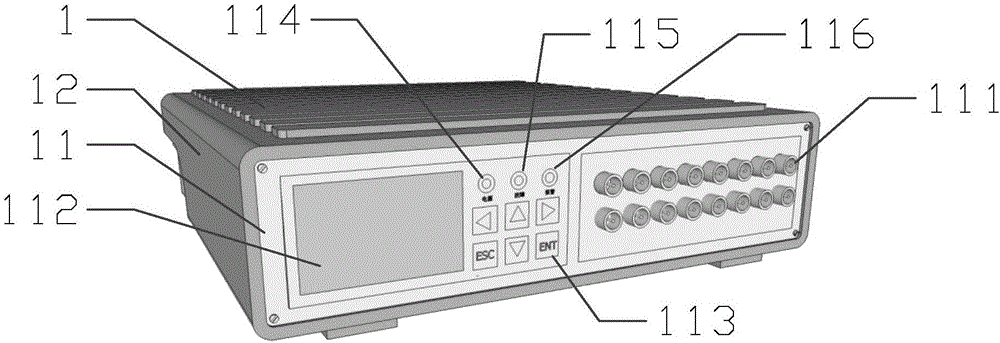

[0023] Such as figure 2 As shown, it is a schematic diagram of the overall structure of the main body of the detection device used in the present invention. The main body 1 consists of a first housing 12, an operati

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap