Novel high-safety tempering furnace

A high-safety, tempering technology, applied in the field of new high-safety tempering furnaces, can solve problems such as delay in production process, waste of time and power, loss, etc., and achieve the effect of avoiding unqualified products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0008] Example 1

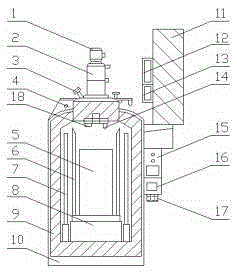

[0009] A new type of high-safety quenching and tempering furnace, including: motor 1, stirring fan 2, observation window 3, furnace cover 4, quenching and tempering room 5, heat shield 6, electric heating element 7, container 8, heat insulation layer 9 , Furnace body 10, furnace cover opening and closing device 11, timer 12, controller 13, temperature probe 14, temperature controller 15, pressure indicator 16, buzzer 17, pressure sensor 18, stirring fan 2 is installed below motor 1 , Install the observation window 3 on one side of the stirring fan 2, install the furnace cover 4 under the stirring fan 2, install the furnace body 10 under the furnace cover 4, install the furnace cover opening and closing device 11 on the furnace body 10 side, and the furnace cover opening and closing device 11 side Install the timer 12, install the controller 13 below the timer 12, install the temperature controller 15 below the furnace cover opening and closing device 11, install t

Example Embodiment

[0010] Example 2

[0011] Put the product to be tempered into the tempering chamber 5, close the furnace cover 4, set the tempering time by the timer 12, the motor 1 drives the stirring fan 2 to stir the furnace appropriately, and the electric heating element 7 heats up on the holding table 8. The article is heated, the temperature sensor 14 measures the temperature in the furnace at all times, and displays the temperature on the temperature controller 15. The staff can observe the temperature change in the furnace through the indicator, and the pressure sensor 18 converts the pressure in the furnace into a numerical value and passes The pressure indicator 16 shows the pressure indicator. When the pressure is too high, it will trigger the buzzer 17 to sound the alarm, and cut off the power supply of the heating element 7 at the same time, to avoid the explosion accident caused by the high pressure in the furnace, when the set quenching time is reached , The timer 12 triggers the con

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap