Pole plate slitting mill with pressing strips and pressing wheel

A rolling cutting machine and polar plate technology, applied in the direction of shearing devices, shearing machine accessories, climate sustainability, etc., can solve problems such as burrs, poor quality of polar plates, easy deformation of polar plates, etc., and achieve correction of deformation Pole plate, reduce vibration amplitude, and prevent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

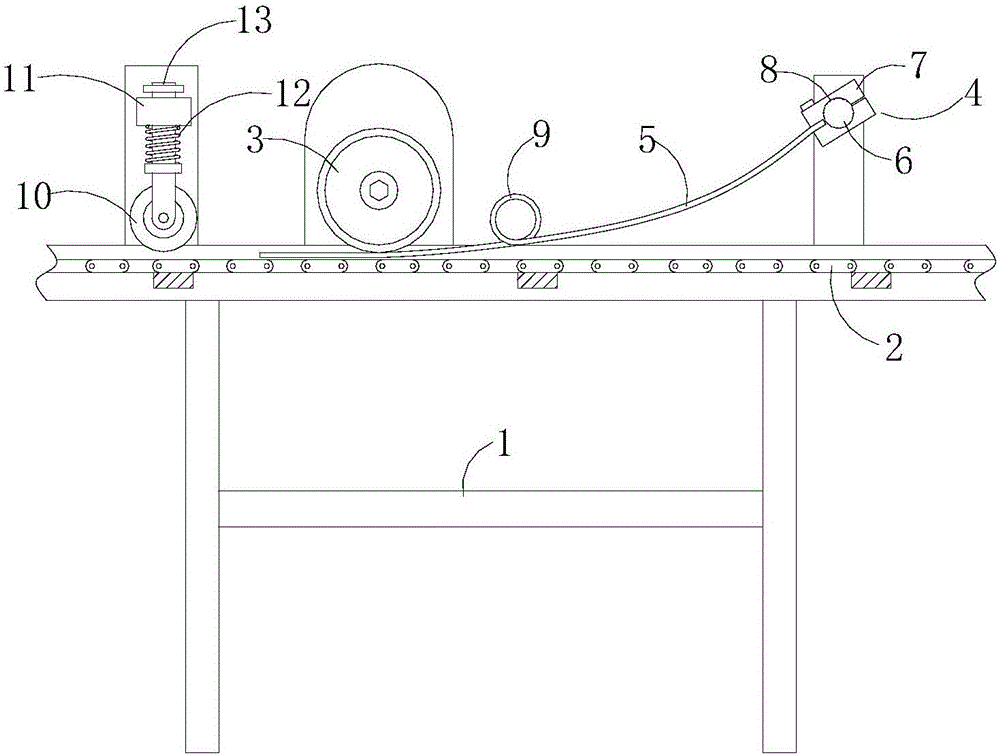

[0017] Such as figure 1 The pole plate rolling machine shown includes a frame 1. A pole plate conveyor chain 2 and a cutter 3 are arranged in the frame 1, and a fixed rod 6 perpendicular to the conveyor chain 2 is arranged above the frame 1. Four jackets 4 are arranged at intervals. Each jacket 4 holds a bead 5 extending along the conveying direction of the plate and crossing the position of the cutter 3 by 10 to 50 cm, which is used to press the plate to avoid the plate from cutting ears. Deformed.

[0018] The upper part of the frame 1 is installed with a cross bar 11, and is provided with a pressure roller bracket 13 penetrating through the cross bar 11. An elastic pressure wheel 10 is installed at the bottom of the pressure wheel bracket 13, and a spring 12 is sleeved on the pressure wheel support 13 to maintain elasticity The force of the pressing wheel 10 on the pole plate, and by rolling the middle of the pole plate, corrects the slight bulge caused by cutting the pole plate

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap