Full-breadth airplane runway sweeping machine

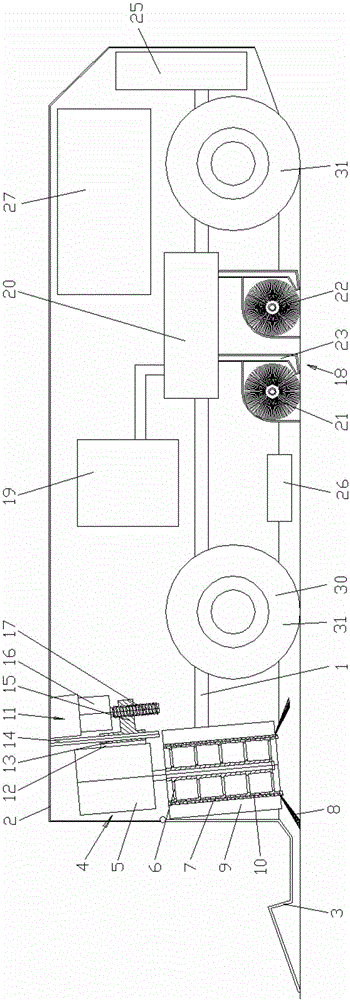

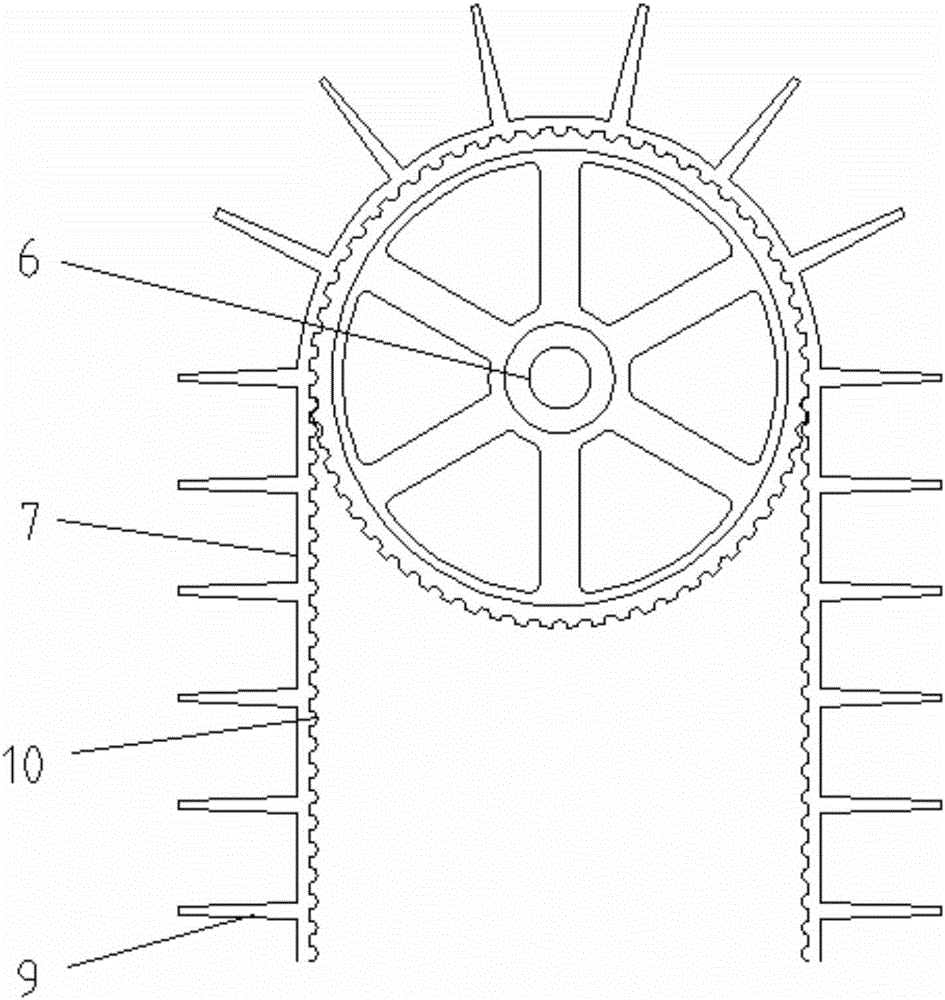

An airstrip and full-format technology, applied in the field of sanitation vehicles, can solve problems such as flight delays, cancellations, safety hazards in production safety, etc., and achieve high transmission capacity, thorough cleaning, and the effect of preventing take-off safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

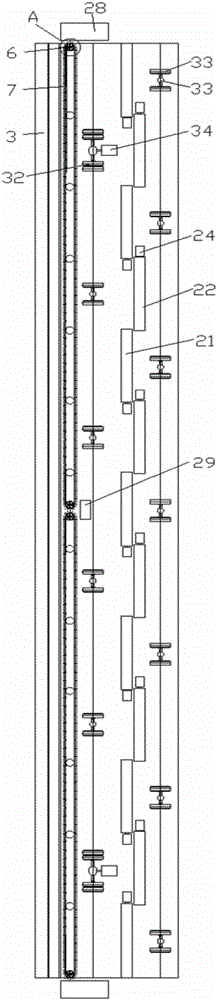

[0027] The first embodiment, the all-wheel steering mode: all the running wheel axles 31 adopt independent steering structure 35, the running wheel axles 31 are arranged in two rows, and the running wheel axles 31 are respectively connected to the frame 1 through elastic suspension. Due to the road conditions of the work site Preferably, it is generally only necessary to equip part of the traveling axle 31 with a motor deceleration and braking device 34, that is, a wheel-side motor, a reducer and a braking device, to form the driving axle 32, and the other traveling axles 31 are driven axles 33, that is, there is no power and Braking device.

Example Embodiment

[0028] The second embodiment, the universal wheel mode with servo guiding mechanism: all the traveling axles 31 are arranged in two rows, the front traveling axle 31 has no steering structure 35, the rear traveling axle 31 adopts universal wheels, and the traveling axles 31 are all elastically suspended Connected to the frame 1, all or part of the front wheel axle 31 is equipped with a motor deceleration brake device 34, which is driven by the wheel side motor through a reducer to form a driving axle 32, and the universal wheel in the rear row is a driven axle 33 ,No power. Taking into account the reversing and steering of the sweeper, there is an electric semi-active direction selection mechanism on the bracket of the universal wheel to prevent sudden reversing.

Example Embodiment

[0029] The third embodiment, the traditional way: all the running wheel axles 31 are arranged in two rows, one of which is the driving wheel axle 32 of torque drive mode, there is no steering mechanism, and all or part of the running wheel axles 31 are equipped with a motor deceleration brake device 34, That is, the driving axle 32 driven by the wheel motor and the reducer; the other row is the driven axle 33, and all the driven axles 33 are provided with an independent servo-motor type steering structure 35; all the traveling axles 31 are connected to the frame 1 through elastic suspension. Connected.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap