Stretchable ultrasonic transducer array

An ultrasonic transducer and transducer technology, applied in instruments, material analysis using sound waves/ultrasonic waves/infrasonic waves, scientific instruments, etc., can solve the problem that hard transducers cannot detect complex curved surfaces, etc., and achieve high-efficiency real-time detection , widen the range, and achieve large-area effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

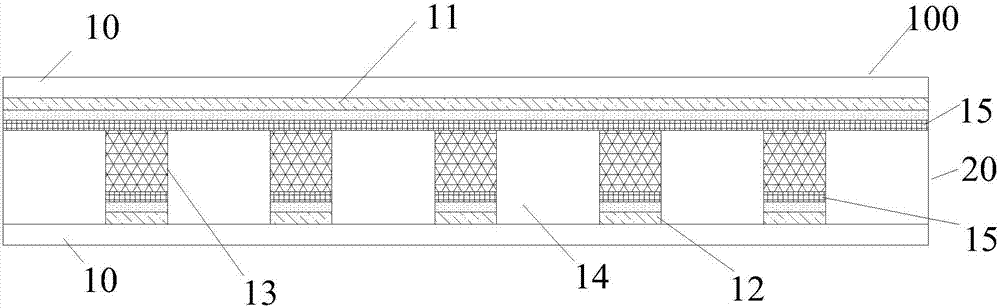

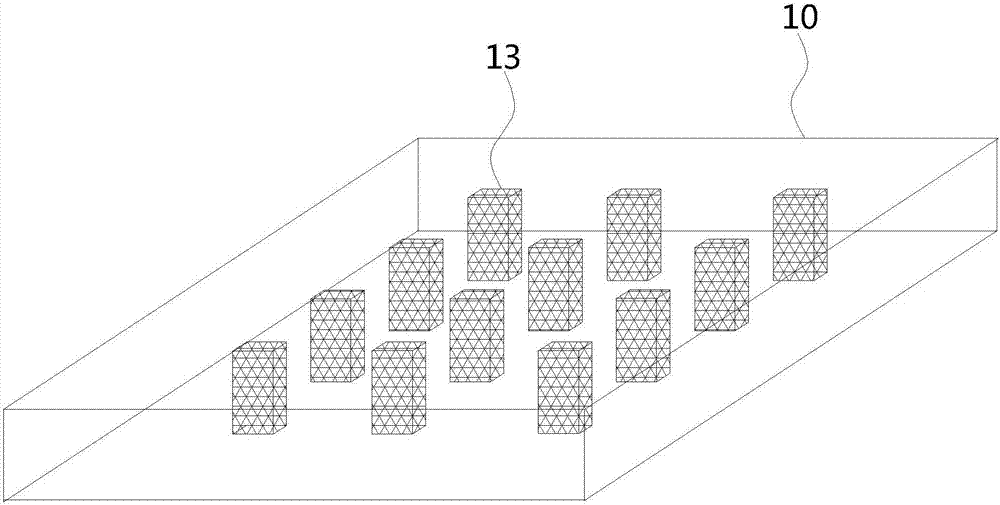

[0020] Such as figure 1 , 2 , 3, 4, and 5, the stretchable ultrasonic transducer array 100 according to one embodiment of the present invention generally includes a detection array 20 , a signal interface and a cladding layer 10 .

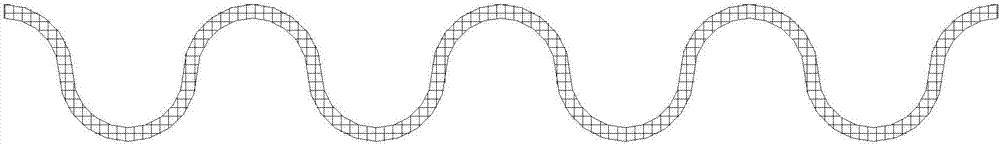

[0021] The detection array 20 includes a plurality of transducers 13 arranged in a predetermined array shape, and the transducers are connected by wires 15 . The transducer 13 in this embodiment is an energy conversion device, which is an ultrasonic testing device made of piezoelectric crystals. Rod shape, thin shell spherical shape, piezoelectric film, etc.

[0022] The shape of the array can be set according to the actual test equipment. The settings here include the test shape of general equipment, that is, the array arrangement that can be applied to most equipment detection; it also includes the shape of the test for special equipment, that is, for specific equipment Display shapes in a specific arrangement of shape settings to obtain more acc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap