Anti-fall locking structure

A locking structure, anti-fall technology, applied in elevators, elevators in buildings, transportation and packaging, etc., can solve the problems of low practicability, complex structure, high cost, and achieve the effect of simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] The present invention will be described below with reference to the drawings.

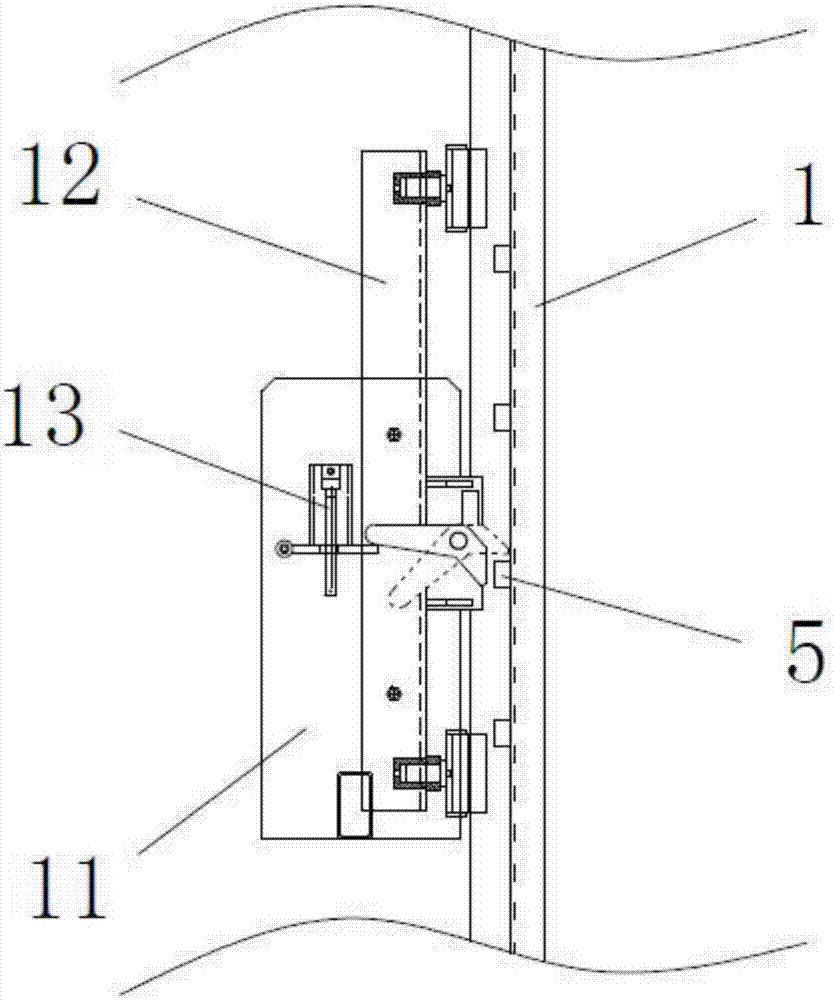

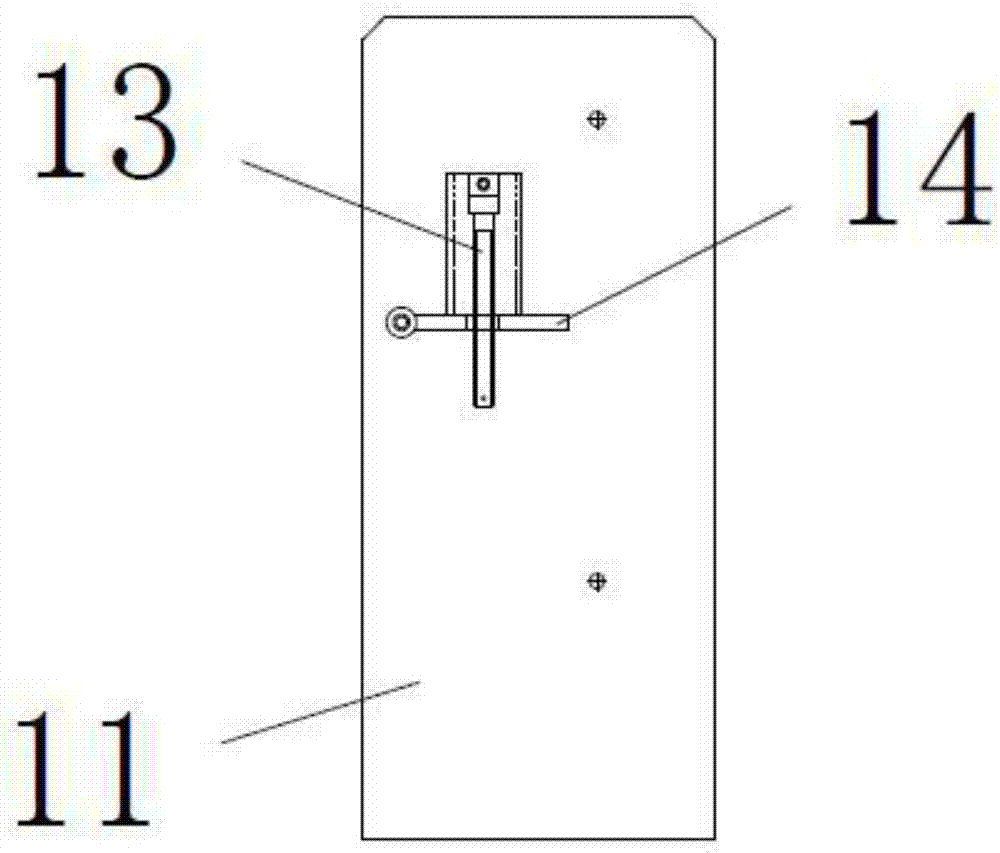

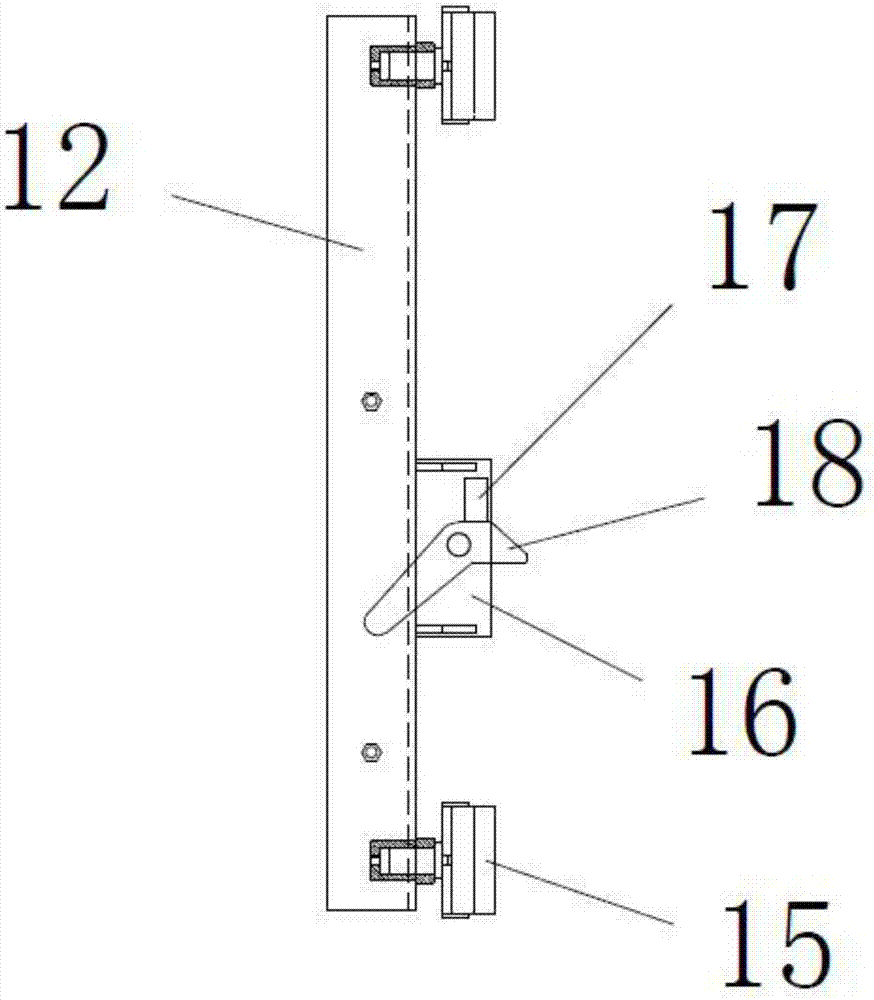

[0014] As attached Figure 1-3 As shown, an anti-fall locking structure according to the present invention includes a column 1, a guide wheel plate 11 and a guide wheel frame 12. The column 1 is provided with a vertical slide rail and a plurality of locks evenly arranged in the vertical direction. Block 5, the guide wheel frame 12 is connected with the guide wheel plate 11; the guide wheel plate 11 is provided with a vertical chain anchor 13 and a horizontal rotating plate 14, one end of the rotating plate 14 is hinged on the guide wheel plate 11 , The chain anchor 13 passes through the rotating plate 14; the guide wheel frame 12 is provided with a slider assembly 15 and a lock arm mounting plate 16. The slider assembly 15 is matched with the slide rail of the column 1, and the lock arm mounting plate 16 A matching block 17 and a hinged locking arm 18 are provided. The front end of the locking ar

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap