Hosiery machine disconnection safety device

The technology of a safety device and a hosiery machine is applied in the directions of knitting, textiles and paper making, which can solve the problems of increased use cost and inconvenience, and achieve the effect of cost saving and simple and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

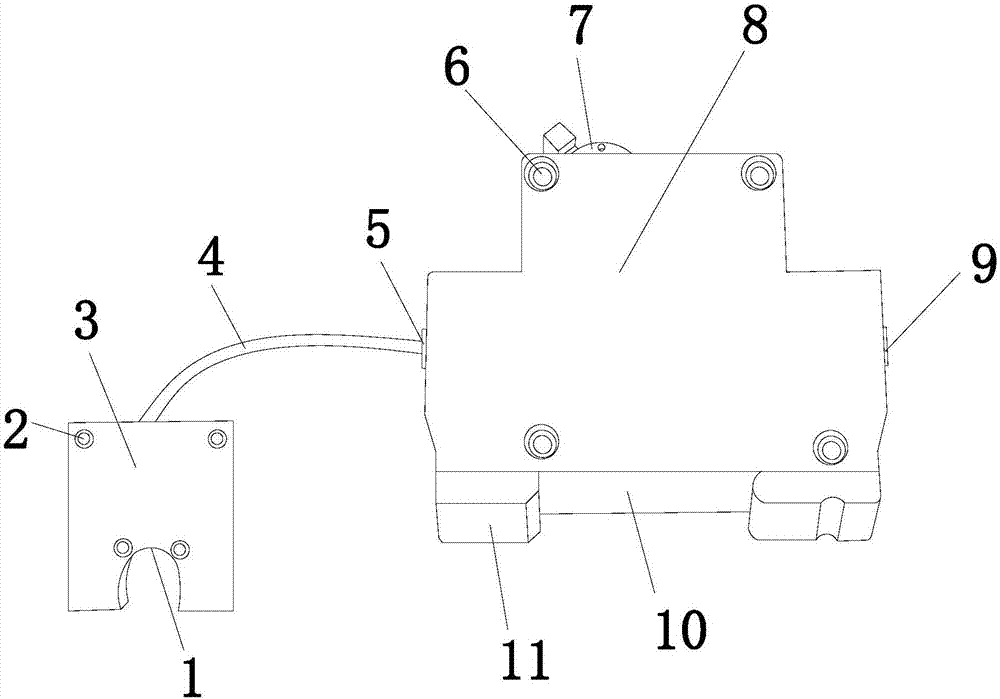

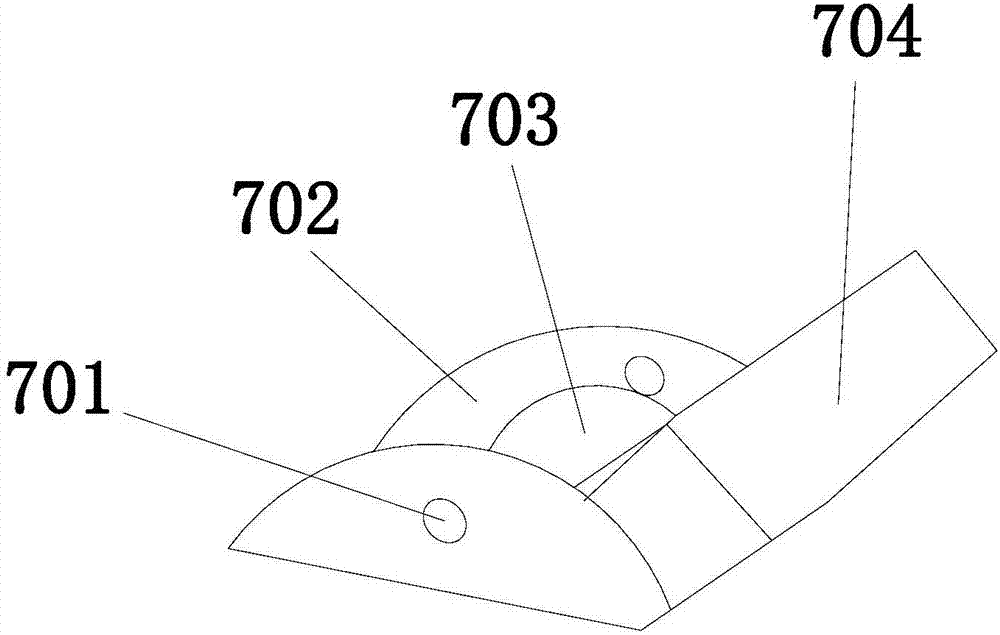

[0018] see figure 1 , figure 2 , the present invention provides a hosiery machine disconnection safety device: its structure includes a groove 1, a sensor screw hole 2, a sensor 3, a connecting line 4, a connection port 5, a circuit breaker screw hole 6, a switch 7, and a circuit breaker 8. No. 2 connection port 9, chassis 10, and base 11. The sensor 3 is provided with a groove 1 and a sensor screw hole 2. The groove 1 has a semicircular structure and is located below the sensor 3. The sensor screw holes 2 are provided with 4 and are located on the left and right sides above the sensor 3 and the left and right sides above the groove 1 respectively. 8 is provided with No. 1 connection port 5, circuit breaker screw hole 6, switch 7, No. 2 connection

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap