Construction method adopting loose-leaf type soil taking and unloading by improving high-frequency vibrating hammer

A high-frequency vibration and construction method technology, which is applied to earth movers/excavators, construction, etc., can solve the problems of inability to realize large-diameter pile foundations, high cost, and large amount of soil borrowed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

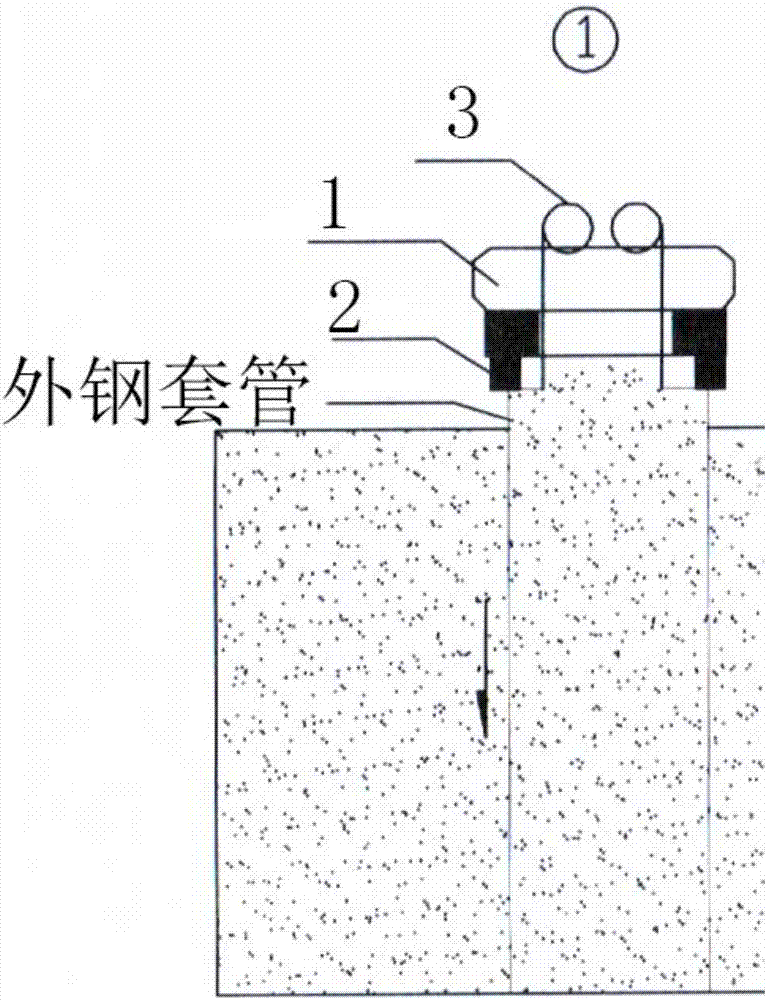

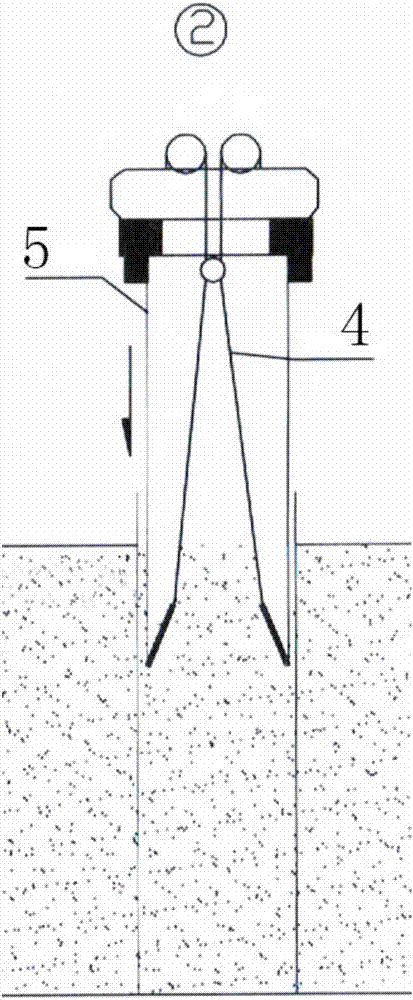

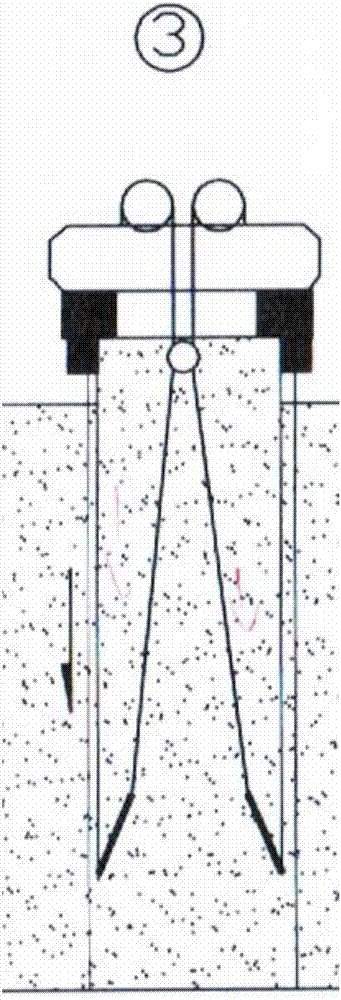

[0023] A construction method of loose-leaf soil picking and unloading by improving the high-frequency vibratory hammer of the present invention will be further described below in conjunction with the accompanying drawings and specific examples.

[0024] First, by improving the structure of the high-frequency vibratory hammer, the soil-absorbing pipe and the soil-absorbing bin are designed as an integral structure;

[0025] Then, use the high-frequency vibrating hammer (1) to first sink the outer steel casing into the ground, and the working range of the integral structure of the soil-taking pipe and the soil-borrowing bin is set inside the outer steel casing, and the high-frequency vibrating hammer (1) passes through the The holder (2) clamps the soil-absorbing pipe (5), and tightens the wire rope (4) of the soil-absorbing pipe (5) through the hoist (3), so that the loose-leaf piece of the soil-absorbing pipe (5) is tightened upwards and close to the soil-absorbing pipe (5) ) inn

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap