Depressurization nipple for controlling annulus pressure of wellbore

A wellbore annulus and pressure technology, applied in the field of oil and gas drilling, can solve the problems of drilling fluid leakage, complicated drilling accidents, high cost, etc., and achieve the effect of reducing friction and improving energy conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

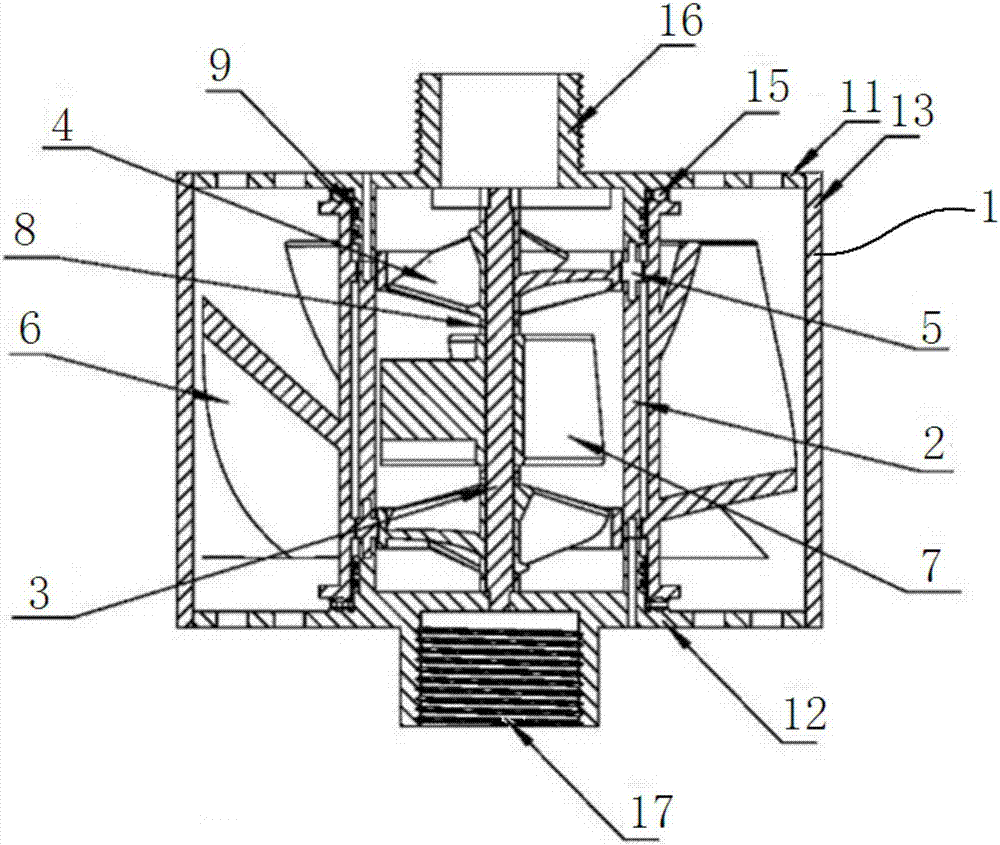

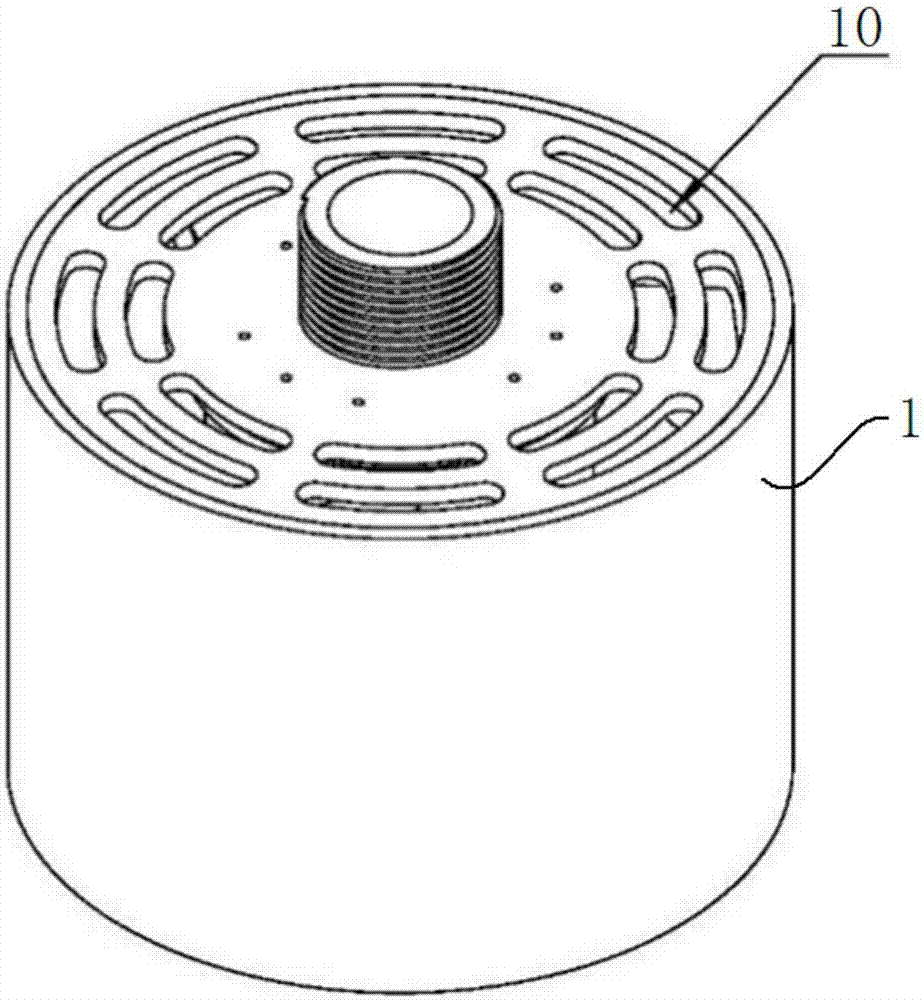

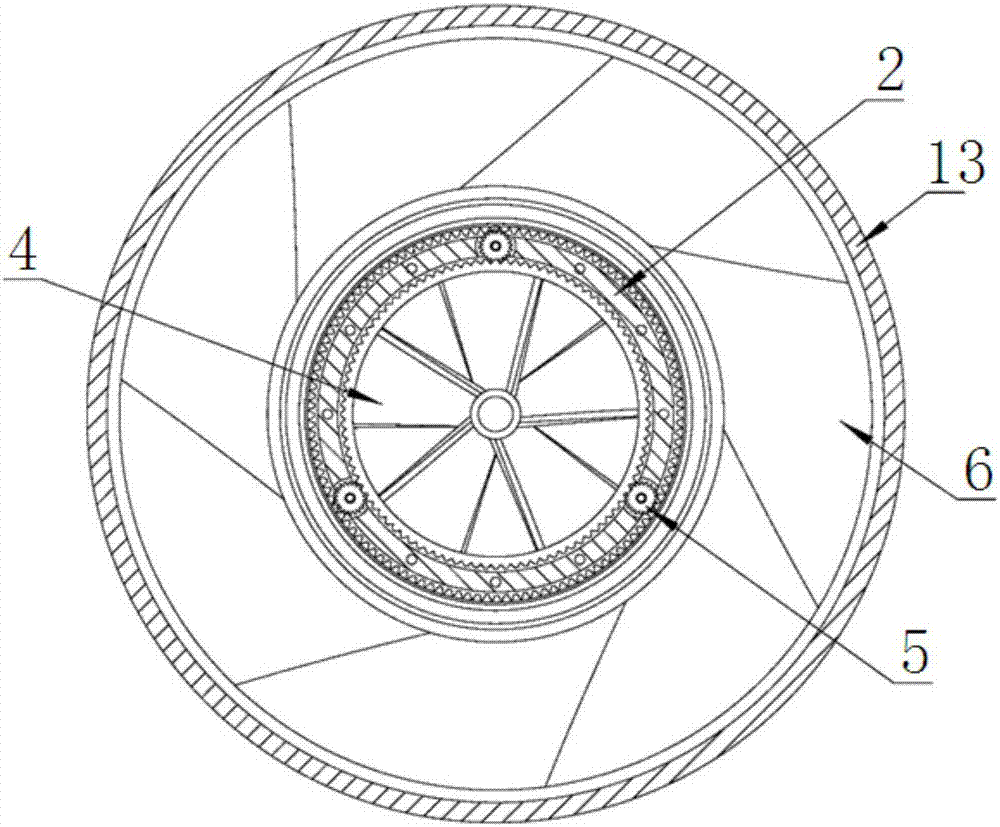

[0022] Such as Figure 1~3 As shown, the present invention proposes a pressure-reducing nipple 100 for controlling wellbore annular pressure, which includes a shell 1, and a cylindrical support wall 2 is fixed inside the shell 1, A fixed shaft 3 is provided, which is arranged on the axis of the support wall 2 . A power impeller 4 is respectively connected to the two ends of the fixed shaft 3. The outer edge of the power impeller 4 is an outer ring gear. A step-down impeller 6 is arranged for rotation, and the inner edge of the step-down impeller 6 is an inner ring gear, and the inner ring gear meshes with the transmission gear 5 .

[0023] Further, the casing 1 includes an upper cover 11 , a lower cover 12 and an outer side wall 13 , and the upper cover 11 and the lower cover 12 are welded to two ends of the outer side wall 13 respectively. The fixed

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap