Manufacturing method of microwave assisted Soxhlet extraction device

A Soxhlet extraction and microwave technology, applied in the field of scientific experiments, can solve the problems of combining Soxhlet extraction devices, taking a long time, and limited improvement of extraction rate, so as to speed up the Soxhlet extraction process, avoid solvent volatilization, The effect of easy temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

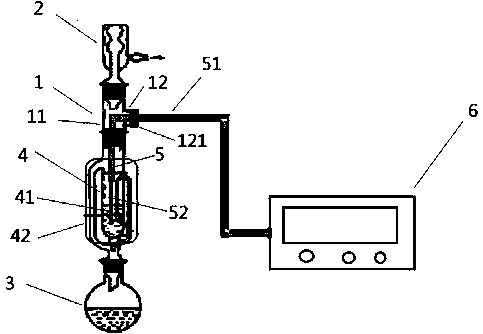

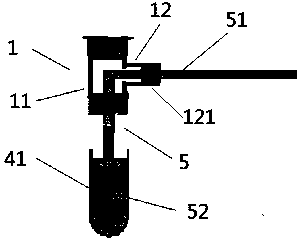

[0019] Such as figure 1 and figure 2 As shown, a microwave Soxhlet extraction device includes a microwave connecting tube 1, a condensation tube 2, a distillation bottle 3 and a Soxhlet extraction tube 4, and a sample cylinder 41 is arranged in the Soxhlet extraction tube, and it is characterized in that: the microwave connecting tube 1 Including the main pipe 11, the branch pipe 12 and the microwave radiator 5, the microwave radiator 5 includes a coaxial cable 51 and a radiation head 52, one end of the coaxial cable 51 is connected to the microwave source 6 through the input terminal, and the other end passes through the microwave connecting pipe in turn The sealing plug inner hole 121 of the branch pipe 12 and the lower opening of the main pipe are connected to the microwave radiation head 52, and the microwave radiation head 52 is a

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap