Supercharger inlet air adjusting device and control method

A technology of air intake adjustment and supercharger, which is applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc., and can solve problems such as increasing product costs, material temperature resistance properties, and strict structural design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

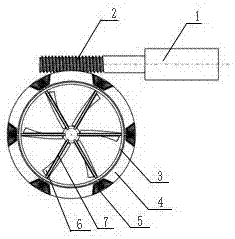

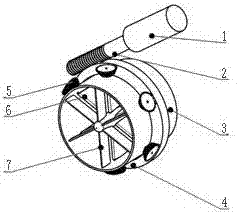

[0018] Referring to the accompanying drawings, a supercharger air intake adjustment device includes a servo motor 1, a worm 2, a housing 3, a linkage ring 4, an adjustable guide vane driven bevel gear 5, an adjustable guide vane 6, and a rectifying vane 7, The servo motor 1 is connected with the worm 2, and the linkage ring 4 is set on the housing 3, the worm 2 meshes with the bevel gear of the linkage ring 4, the bevel gear of the linkage ring 4 meshes with the driven bevel gear 5 of the adjustable guide vane, and the The housing 3 is provided with adjustable guide vanes 6 and rectifying vanes 7 .

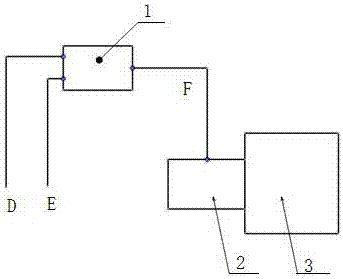

[0019]According to the control method of the supercharger air intake regulating device, the supercharger air intake regulating device can be used as an optional part of the supercharger assembly; The intake flow and impeller speed of the compressor change; the ECU sends control commands to the control unit of the servo motor 1 according to the input signals of the intake flow and the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap