Blind hole machining technology

A processing technology, blind hole technology, applied in the field of mechanical processing, can solve problems such as inconvenience in work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Blind hole processing technology, including the following steps:

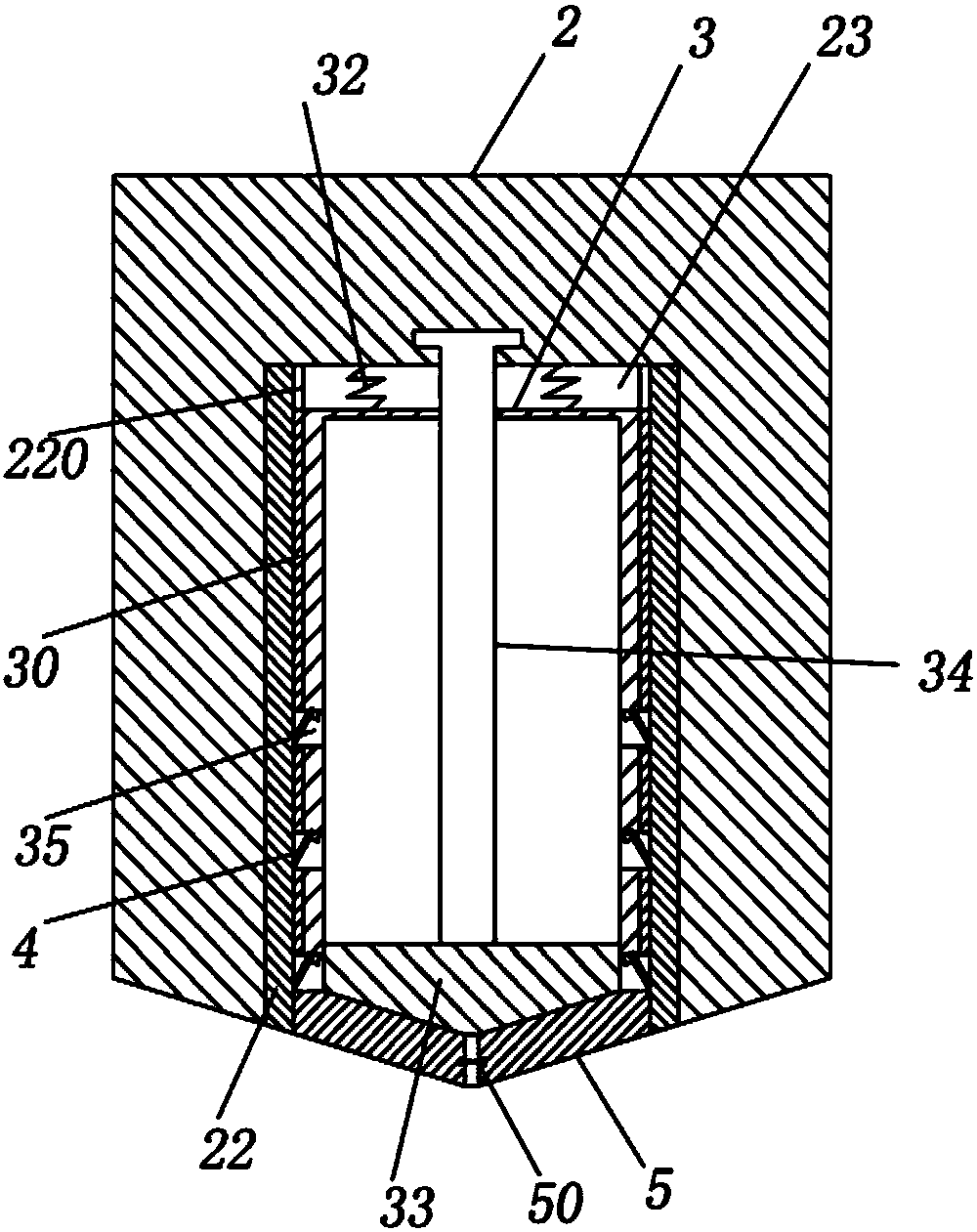

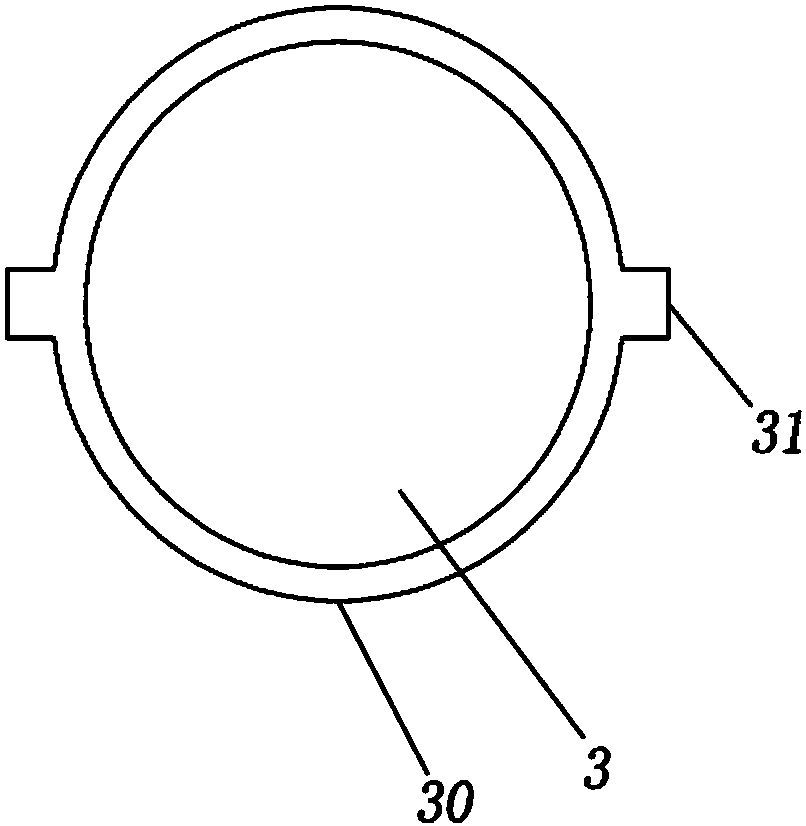

[0027] Step 1, preparation: prepare a drill 2 and a frame 1 with an electromagnet 10, the drill 2 is slidably connected with a chip suction pipe 3 that can automatically absorb wood chips by using the electromagnet 10. The specific structure is as follows:

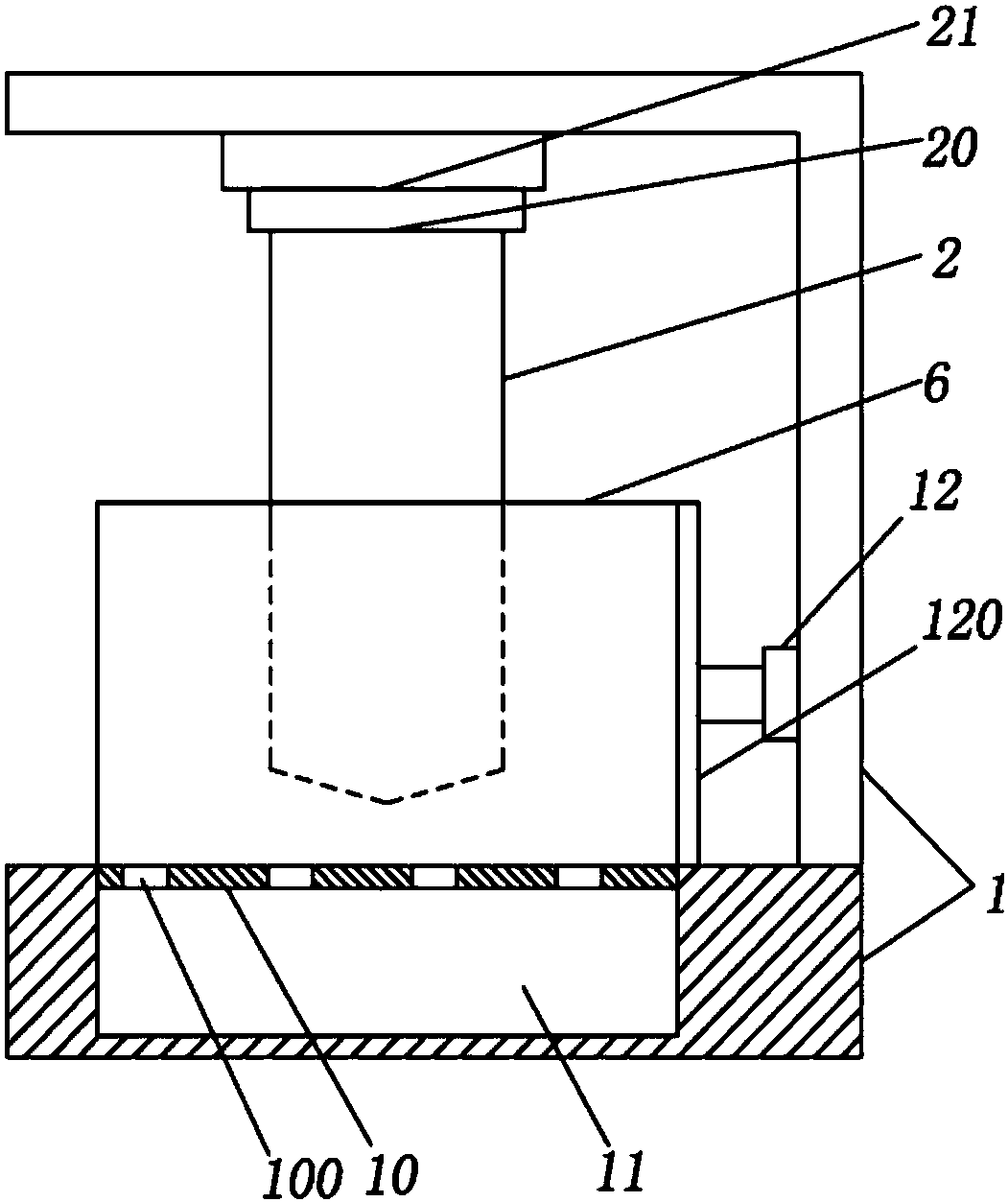

[0028] Such as figure 1 As shown, a rotating part that drives the drill 2 to rotate and a lifting part that drives the drill 2 to lift are installed on the top of the drill 2. The rotating part can directly select the motor 20 in the prior art, and the lifting part can directly select the hydraulic cylinder 21.

[0029] The frame 1 is welded with an electromagnet 10 for supporting the workpiece. The electromagnet 10 is in the shape of a net, and is provided with a number of chip leakage holes 100. The frame 1 is provided with a chip storage tank 11 located below the electromagnet 10. The chip hole 100 realizes collecting the wood chips on the electro

Embodiment 2

[0038] The difference between this embodiment and embodiment 1 is:

[0039] The length of the chip suction pipe 3 in step 1 is 33cm; the static electricity generated by the friction between the cotton layer 22 and the plastic layer 30 is 800uA;

[0040] In step 2, the rotating speed of the drill 2 is 1300r / min, and the falling speed of the drill 2 is 20mm / min; the depth of the blind hole is 12cm;

[0041] The operating current of the electromagnet 10 in step 3 is 1300A;

[0042] In step 4, the distance that the chip suction pipe 3 moves up automatically is 18cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap