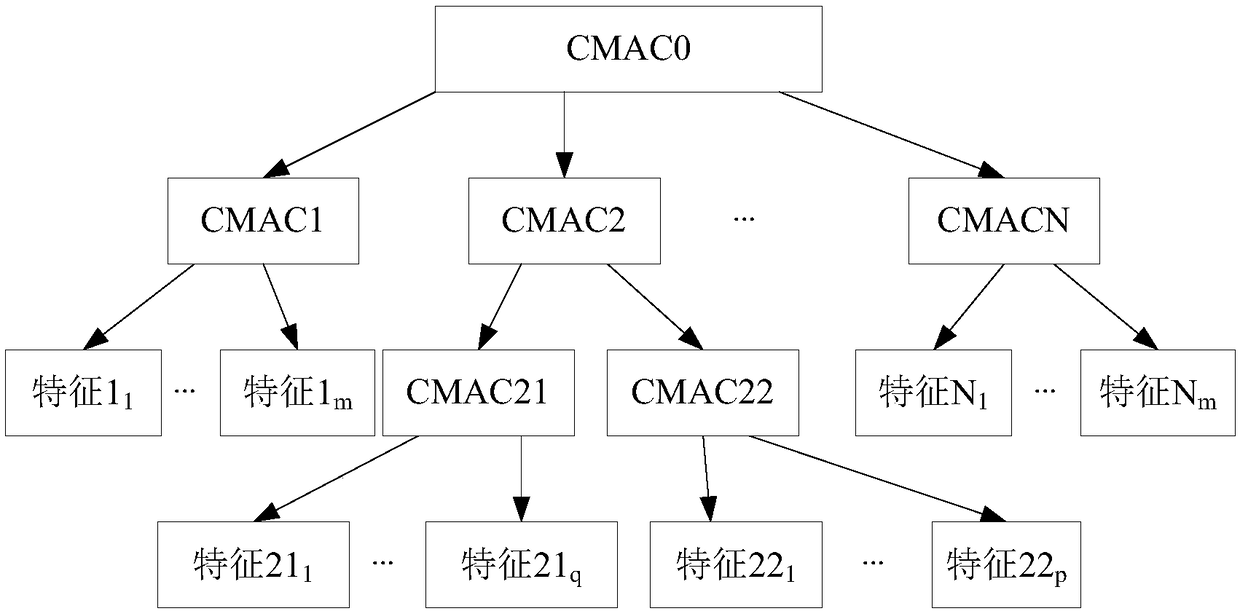

Multilevel stacked CMAC model for equipment performance evaluation

A technology of equipment performance and model, which is applied to the monitoring of mechanical equipment, engine functions, wind turbines, etc., can solve the problem that the CMAC model is difficult to accurately and effectively evaluate the performance situation, loss, etc., achieve simple and feasible performance evaluation, avoid storage problems, The effect of enhancing usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

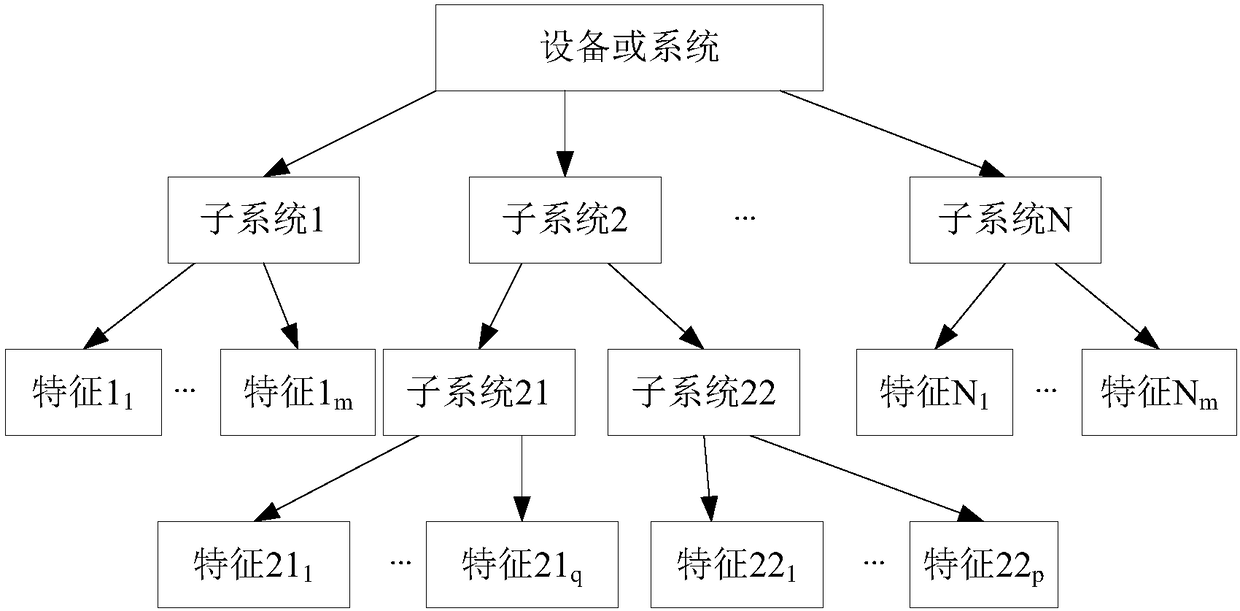

[0040] Embodiment 1. The main components of typical horizontal-axis wind power generation equipment include several parts such as blades, hubs, transmission systems (main shaft, couplings and gearboxes), generators, control systems, yaw systems, and towers. The performance evaluation of wind power generation equipment is mainly carried out on these key components. Corresponding to different key components, a multi-layer hierarchical subsystem model can be established. The first layer is the whole wind power generation equipment, the second layer includes blades, transmission system, generator, control system, and yaw system, and the transmission system can be divided into two subsystems, the main shaft and the gearbox, on the third layer. The division of subsystems should conform to the specific conditions of the equipment.

Embodiment 2

[0041] Embodiment 2. Corresponding to each subsystem of the bottom layer, the signals to be measured are also different. For example, in embodiment 1, the main shaft mainly measures vibration signals, while the control system mainly measures voltage and current, and the air pressure and hydraulic systems mainly measure pressure and temperature. , oil level, etc.

Embodiment 3

[0042] Embodiment 3. Corresponding to each subsystem, the feature quantity input by CMAC should be reasonably extracted according to the signal form. For example, general signals, such as voltage and current, can extract the maximum value, minimum value, and average value, but for vibration signals, except for time In addition to domain features, the magnitude of the frequency domain after Fourier transform can also be extracted.

[0043] Divide the equipment into a multi-level subsystem structure, and these subsystems constitute a relatively independent part in terms of structure or function; use this hierarchical structure of the equipment to establish a corresponding multi-level stacked CMAC model, so that each CMAC corresponds to a subsystem, The input of each CMAC can be reduced, which meets the situation that CMAC is suitable for inputting 3-5 feature quantities, and avoids the storage problem caused by too much input of CMAC.

[0044]Using this model can solve the problem

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap