Container centring weighing mechanism

A weighing mechanism and container technology, applied in the direction of weighing, measuring devices, instruments, etc., can solve the problems of increasing logistics transfer time and reducing logistics efficiency, so as to reduce logistics transfer time, facilitate installation, reduce operation time and operation steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

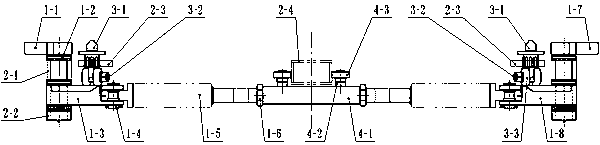

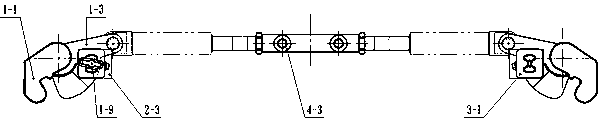

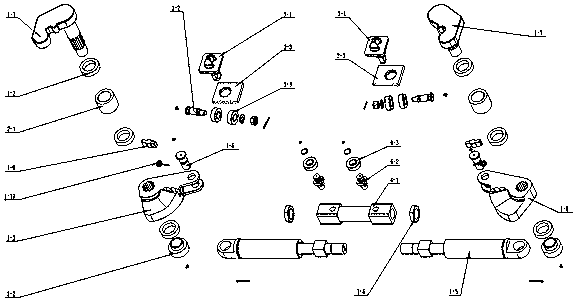

[0018] figure 1 , figure 2 , image 3 In the middle, the centering mechanism is composed of left centering hook 1-1, right centering hook 1-7, left weighing seat 1-3, right weighing seat 1-8, double-headed cylinder 1-5 and so on. The left centering hook 1-1, the right centering hook 1-7 are hinged with the upper shaft sleeve 2-1 and the lower shaft sleeve 2-2 on the platform 2, the left weighing seat 1-3, the right weighing seat 1- 8 It is fixedly connected with the left centering hook 1-1 and the right centering hook 1-7 through a spline, and a thrust bearing 1- is installed between the planes contacting the upper bushing 2-1 and the lower bushing 2-2. 2. The double-headed cylinder 1-5 is hinged with the left weighing seat 1-3 and the right weighing seat 1-8 through the pin 1-4. The weighing mechanism 3 is connected with the spline sleeve 2-3 on the platform 2 through the spline on the lifting cone 3-1, so that it can only move up and down, and the lifting cone 3-1 and the suppo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap